Stainless Steel Sheet/Plate 420 for Surgery

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet/Plate 420 for Surgery

Description of Stainless Steel Sheet/Plate 420 for Surgery:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel Sheet/Plate 420 for Surgery:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Application of Stainless Steel Sheet/Plate 420 for Surgery:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many application

s.There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates,

bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipme

nt Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion re

sistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steam

cleaned and sterilized and does not need paint or other surface finishes..

Specifications of Stainless Steel Sheet/Plate 420 for Surgery:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics Stainless Steel Sheet/Plate 420 for Surgery:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

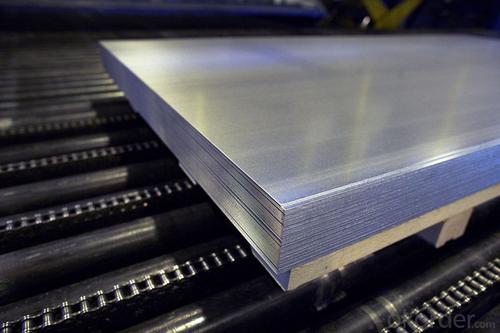

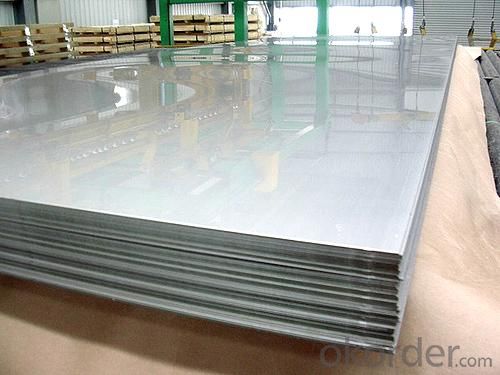

Images of Stainless Steel Sheet/Plate 420 for Surgery:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ of Stainless Steel Sheet/Plate 420 for Surgery:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What are the benefits of using perforated stainless steel sheets in acoustics?

- Perforated stainless steel sheets offer several benefits when it comes to acoustics. Firstly, they provide excellent sound absorption properties. The evenly distributed perforations in the stainless steel sheets help to break up and scatter sound waves, reducing their energy and preventing them from bouncing back into the room. This helps to minimize echo and reverberation, resulting in a more comfortable and intelligible acoustic environment. Additionally, perforated stainless steel sheets can be customized to meet specific acoustic requirements. The size, shape, and pattern of the perforations can be adjusted to achieve different levels of sound absorption. This allows for precise control over the acoustics of a space, making it suitable for a variety of applications such as concert halls, recording studios, theaters, or even office spaces. Furthermore, perforated stainless steel sheets are durable and long-lasting. Stainless steel is known for its corrosion resistance, which means that the sheets can withstand harsh environments without deteriorating over time. This makes them suitable for both indoor and outdoor applications, ensuring a consistent acoustic performance for years to come. Another advantage of using perforated stainless steel sheets is their aesthetic appeal. The perforations can be designed in various patterns and sizes, offering a visually pleasing and modern look. This makes them a popular choice for architectural and design applications, where both acoustics and aesthetics are important. In summary, the benefits of using perforated stainless steel sheets in acoustics include excellent sound absorption properties, customizable options, durability, and an attractive appearance. These qualities make them a versatile and effective solution for improving the acoustic performance of various spaces.

- Q: Are stainless steel sheets good for cryogenic storage?

- Yes, stainless steel sheets are suitable for cryogenic storage due to their excellent resistance to low temperatures and high strength. They can withstand extreme cold without becoming brittle or losing structural integrity, making them a reliable choice for storing materials at cryogenic temperatures.

- Q: What are the different types of stainless steel sheet edges available?

- There are several different types of stainless steel sheet edges available, each offering its own unique advantages and characteristics. 1. Mill Edge: This is the standard edge finish produced during the manufacturing process. It has a straight, sharp edge with no additional treatment or finishing. Mill edge stainless steel sheets are commonly used in industrial applications where aesthetics are not a priority. 2. Slit Edge: Slit edge stainless steel sheets are created by cutting the sheet along its length, resulting in a slightly rounded edge. This type of edge is commonly used in applications where safety is a concern, as it reduces the risk of sharp edges causing injury. 3. Sheared Edge: Sheared edge stainless steel sheets are created by cutting the sheet along its width using shearing blades. This process produces a clean, straight edge without any additional finishing. Sheared edge sheets are often used in applications where precise dimensions are required. 4. Deburred Edge: Deburred edge stainless steel sheets have gone through a process to remove any sharp or rough edges, resulting in a smooth and safe edge finish. Deburring is often done using abrasive materials or specialized machinery. These sheets are commonly used in applications where safety and aesthetic appearance are both important. 5. Rolled Edge: Rolled edge stainless steel sheets have a curved or rounded edge, created by rolling the sheet during the manufacturing process. This edge type is commonly used in applications where a smoother, more finished appearance is desired. Rolled edge sheets are also easier to handle and less likely to cause injury during installation. Overall, the choice of stainless steel sheet edge depends on the specific requirements of the application, including safety concerns, aesthetic preferences, and dimensional accuracy.

- Q: Are stainless steel sheets suitable for corrosive environments?

- Stainless steel sheets are well-suited for corrosive environments, given their corrosion resistance properties. They are an excellent choice for situations where moisture, chemicals, or other corrosive substances are present. This can be attributed to the inclusion of chromium in stainless steel, which creates a protective layer that prevents rusting or corrosion. Moreover, stainless steel sheets come in various grades, like 304 and 316, offering different degrees of corrosion resistance. Consequently, stainless steel sheets are widely employed in vital industries such as chemical processing, marine settings, food and beverage production, and pharmaceuticals, where safeguarding against corrosion is of utmost importance.

- Q: What is the ductility of stainless steel sheets?

- Stainless steel sheets possess a remarkable quality known as ductility. This quality enables them to endure tensile stress without succumbing to fractures or breaks. The stainless steel material is renowned for its outstanding ductility, which grants it the ability to withstand stretching, bending, or hammering without compromising its structural integrity. This exceptional attribute endows stainless steel sheets with great versatility, rendering them suitable for an extensive array of applications such as construction, automotive manufacturing, and kitchen appliances. The high ductility of stainless steel empowers it to be effortlessly molded into intricate shapes or rolled into thin sheets, making it an ideal choice for delicate designs or structures with thin walls. Moreover, the ductility of stainless steel also facilitates easy welding, solidifying its status as a favored option for fabrication processes.

- Q: How do you form stainless steel sheets into different shapes?

- Different shapes can be achieved with stainless steel sheets by employing various processes, including bending, rolling, and welding. The choice of method depends on the desired shape and the thickness of the sheet. To form stainless steel sheets into shapes like cylinders or boxes, bending is commonly used. This involves clamping the sheet between a punch and a die and applying force to create the desired bend. By adjusting the pressure and the distance between the punch and die, the angle and radius of the bend can be controlled. Rolling is another technique used to form stainless steel sheets into curved or cylindrical shapes. This process entails passing the sheet through a series of rollers, which gradually bend the material into the desired shape. The diameter and curvature of the final shape can be altered by changing the spacing and alignment of the rollers. For more complex shapes, welding is often combined with bending or rolling. Multiple stainless steel sheets are joined together using heat and pressure to create the desired form. This enables the creation of intricate shapes, such as cones or irregular geometries. In addition to these methods, specialized equipment like hydraulic presses or hydroforming can be employed to shape stainless steel sheets. These techniques involve applying high pressure or fluid pressure to the sheet, resulting in deformation and the desired shape. It is crucial to note that forming stainless steel sheets necessitates skilled operators and precise machinery to ensure accuracy and quality. Moreover, the properties of the stainless steel, such as thickness and composition, can also impact the feasibility and success of the forming process.

- Q: Can stainless steel sheets be used for magnetic shielding?

- To a certain extent, stainless steel sheets can be utilized for magnetic shielding. Although stainless steel is not intrinsically magnetic, it possesses some magnetic properties due to the presence of iron, a magnetic material, in stainless steel alloys. This enables stainless steel sheets to exhibit weak magnetic characteristics. Nevertheless, the magnetic shielding capabilities of stainless steel sheets are limited when compared to materials specifically engineered for magnetic shielding, such as mu-metal or nickel-iron alloys. These materials have a higher permeability, meaning they can redirect and absorb magnetic fields more efficiently than stainless steel. However, stainless steel sheets can still offer some level of magnetic shielding, particularly in environments with lower intensity magnetic fields. They can assist in reducing the transmission of magnetic fields from one area to another, which can be beneficial in certain applications. Nonetheless, for situations that require high-intensity or sensitive magnetic shielding, it is recommended to utilize specialized magnetic shielding materials for optimal effectiveness.

- Q: What are the different types of surface treatments available for stainless steel sheets?

- There are several types of surface treatments available for stainless steel sheets, each serving a different purpose and offering unique benefits. 1. Mill Finish: This is the most basic type of surface treatment and refers to the finish that is achieved directly from the mill after the stainless steel sheet is manufactured. It has a smooth, dull appearance and is often used when a clean, unadorned look is desired. 2. Brushed Finish: Also known as satin finish, this treatment involves brushing the stainless steel surface with a fine abrasive material to create a pattern of fine parallel lines. This finish provides a decorative, textured look while also hiding any surface imperfections or scratches. 3. Mirror Finish: As the name suggests, this treatment creates a highly reflective surface that resembles a mirror. It is achieved through a process of polishing the stainless steel sheet with progressively finer abrasives until a glossy, reflective finish is achieved. This finish is commonly used in decorative applications where a high level of shine is desired. 4. Bead Blasted Finish: This treatment involves blasting the stainless steel surface with tiny glass beads under high pressure. It creates a uniform, matte texture with a slightly rough feel. Bead blasted finish is often used in architectural applications to achieve a modern, industrial look. 5. Etched Finish: Etching involves applying an acid or chemical solution to the stainless steel surface to create intricate patterns or designs. This treatment allows for a high level of customization and is commonly used in architectural, signage, and decorative applications. 6. PVD Coating: Physical Vapor Deposition (PVD) is a process where a thin film of a specific material is deposited onto the stainless steel surface using a vacuum chamber. This coating can provide various colors and finishes, such as gold, black, or bronze, while also enhancing the durability and corrosion resistance of the stainless steel sheet. These are just a few examples of the different types of surface treatments available for stainless steel sheets. The choice of treatment depends on the desired aesthetic, functionality, and application requirements.

- Q: What about black titanium stainless steel?

- What I do is teaching: first, teach you how to make black stainless steel plate with mirror stainless steel plate. Second teach you how to remove this layer of black, revealing mirror stainless steel. These two items are the main processes for making black titanium plate labels.

- Q: Are stainless steel sheets resistant to saltwater corrosion?

- Stainless steel sheets possess a high level of resistance against corrosion caused by saltwater. The exceptional corrosion resistance of stainless steel is widely recognized, rendering it an ideal material for use in environments exposed to saltwater. The presence of chromium in stainless steel results in the formation of a protective oxide layer on the surface, effectively acting as a barrier against corrosion. This oxide layer serves to shield the steel from direct contact with saltwater, thus minimizing the risk of corrosion. Moreover, stainless steel grades such as 316 and 316L are specifically engineered to provide enhanced resistance against saltwater corrosion, further increasing their suitability for marine applications. In conclusion, the outstanding corrosion resistance properties of stainless steel sheets make them a dependable option for saltwater environments.

Send your message to us

Stainless Steel Sheet/Plate 420 for Surgery

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords