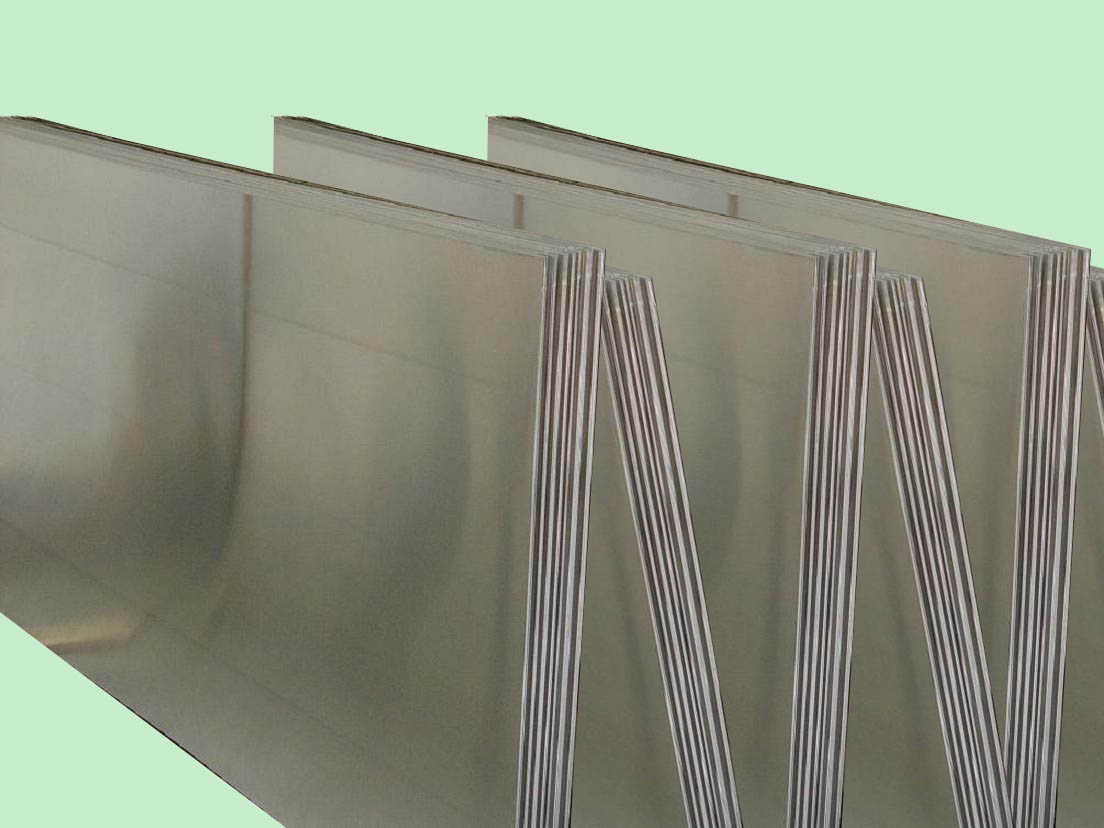

420 Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

420 Stainless Steel Sheet

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

0.16-0.25 |

max1.00 |

max1.00 |

max0.04 |

max0.03 |

--- |

12.00-14.00 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥225 |

≥520 |

≥ 18 |

≥234 |

≥97 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q: What are the common length tolerances for stainless steel strips?

- The common length tolerances for stainless steel strips typically vary depending on the specific industry standards and requirements. However, common length tolerances for stainless steel strips can range from +/- 0.005 inches to +/- 0.030 inches, or even tighter tolerances depending on the precision needed for the application.

- Q: How do you prevent intergranular corrosion of stainless steel strips?

- To prevent intergranular corrosion of stainless steel strips, several measures can be taken. One of the most effective ways is to use stainless steel that has been properly heat treated and solution annealed, as this helps to eliminate carbide precipitation at grain boundaries. Additionally, utilizing low carbon grades of stainless steel can also reduce the susceptibility to intergranular corrosion. Another crucial step is to ensure proper cleaning and passivation of the stainless steel strips, which removes contaminants and promotes the formation of a protective oxide layer on the surface. Regular inspection and maintenance, such as avoiding exposure to aggressive environments and promptly repairing any damages or defects, can further help in preventing intergranular corrosion.

- Q: How do you prevent stainless steel strips from rusting?

- To prevent stainless steel strips from rusting, it is important to regularly clean them using mild soap and water, and dry them thoroughly afterwards. Additionally, applying a thin layer of oil or a specialized stainless steel cleaner can help create a protective barrier against moisture and prevent rust formation.

- Q: Can stainless steel strips be used in heat-resistant furnaces?

- Yes, stainless steel strips can be used in heat-resistant furnaces. Stainless steel is known for its high temperature resistance, making it suitable for use in furnaces that require heat-resistant materials. It has excellent oxidation resistance, which enables it to withstand high temperatures without corroding or deforming. Additionally, stainless steel has good thermal conductivity, allowing it to distribute heat evenly throughout the furnace. Its durability and strength also make it a reliable choice for withstanding the harsh conditions inside a heat-resistant furnace. Overall, stainless steel strips are a suitable material for use in heat-resistant furnaces due to their high temperature resistance, corrosion resistance, thermal conductivity, and durability.

- Q: Are stainless steel strips suitable for high-temperature exhaust systems?

- Stainless steel strips prove to be a fitting option for high-temperature exhaust systems. Boasting resistance to corrosion and heat, stainless steel remains strong and intact even when exposed to elevated temperatures. Its remarkable ability to resist oxidation makes it ideal for scenarios where exhaust gases reach heightened temperatures. Stainless steel strips exhibit the capacity to endure the extreme heat generated by exhaust systems, ensuring their longevity and dependability. Moreover, stainless steel's immunity to corrosion and rust enables it to withstand the harsh conditions and corrosive elements present in exhaust systems. In conclusion, stainless steel strips are a suitable choice for high-temperature exhaust systems due to their heat resistance, durability, and corrosion resistance properties.

- Q: Can 111 stainless steel strips be coated or plated for added protection?

- Yes, 111 stainless steel strips can be coated or plated for added protection. Coating or plating the strips with a protective layer can enhance their resistance to corrosion, wear, and other forms of damage. The specific coating or plating material used will depend on the desired level of protection and the intended application of the strips. Common coating options for stainless steel include epoxy, acrylic, and powder coatings, while plating options may include nickel, chrome, or zinc. It is important to carefully consider the intended use and environment of the strips to select the most suitable coating or plating technique.

- Q: How do stainless steel strips resist intergranular corrosion in welding?

- The primary reason why stainless steel strips are resistant to intergranular corrosion during welding is the presence of chromium. Chromium forms a protective oxide layer on the surface of the steel, which acts as a barrier against oxygen and other corrosive agents. This oxide layer, also known as a passive film, prevents these agents from reaching the underlying metal. During the welding process, the high temperatures can cause the formation of chromium carbides at the weak grain boundaries of the stainless steel. These carbides can reduce the chromium content, making the steel vulnerable to intergranular corrosion. To prevent this, stainless steel strips are typically alloyed with elements such as niobium or titanium. These elements have a strong attraction to carbon. When combined with carbon, they form carbides, allowing the chromium to remain free and form the protective oxide layer. This process is referred to as carbide precipitation or sensitization. Furthermore, stainless steel strips can undergo a heat treatment process called solution annealing or sensitization annealing. This involves heating the steel to a specific temperature and holding it there for a certain period of time. This process allows the carbides to dissolve back into the steel matrix, restoring the chromium content at the grain boundaries and eliminating the susceptibility to intergranular corrosion. In conclusion, the combination of alloying elements and heat treatment plays a crucial role in maintaining the corrosion resistance of stainless steel strips during welding. They prevent the formation of chromium-depleted regions and ensure the integrity of the protective oxide layer.

- Q: Are stainless steel strips suitable for furnace parts?

- Yes, stainless steel strips are suitable for furnace parts. Stainless steel is known for its high heat resistance, durability, and corrosion resistance, making it a suitable material for furnace parts that are exposed to high temperatures and harsh environments.

- Q: Are 111 stainless steel strips suitable for heat recovery systems?

- Yes, 111 stainless steel strips are suitable for heat recovery systems. Stainless steel is known for its high heat resistance and durability, making it an excellent choice for heat recovery applications.

- Q: Can stainless steel strips be easily welded?

- Certainly, welding stainless steel strips is a breeze. Renowned for its remarkable weldability owing to its elevated melting point, limited thermal conductivity, and commendable heat resistance, stainless steel shines. TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding are the go-to techniques for welding stainless steel strips. These methods facilitate meticulous regulation of the welding procedure and yield robust and long-lasting welds. Furthermore, stainless steel strips frequently find their way into diverse sectors such as automotive, construction, and manufacturing, where welding serves as a prevalent method of joining.

1. Manufacturer Overview

| Location | Guangzhou,China |

| Year Established | 2001 |

| Annual Output Value | Above US$0.5 Million |

| Main Markets | Southeast Asia, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 10 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

420 Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords