AISI304 201 316 321 430 stainless steel coil JIS EN DIN GB ASTM standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

AISI304 201 316 321 430 stainless steel coil JIS EN DIN GB ASTM standard

Product Description

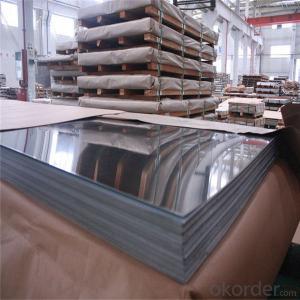

Description of stainless steel coil

Product name | AISI304 201 316 321 430 stainless steel coil JIS EN DIN GB ASTM standard |

Specification | Thickness: Cold rolled: 0.03-3mm, Hot Rolled: 3-120mm Width: 100-2000mm Length: 1000-6000mm or coil Customized sizes are accepted |

Standard | ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

Finish | NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish and so on |

Material | 201, 202, 304, 304L, 310S, 316, 316L, 309s, 321, 410, 420, 430, 441, 904L |

Brand Name | TISCO, Bao Steel, LISCO, JISCO, ZPSS, KRUPP |

Place of Origin | Shanxi of China (Mainland) |

Technical treatment | Cold Rolled, Hot Rolled |

Port of Loading | Tianjin, Shanghai, Ningbo, Guangzhou |

Terms of Delivery | FOB, CFR, CIF, CNF, EX-WORK |

Terms of Payment | L/C, T/T (30% deposit) |

Packing | Standard export sea-worthy packing |

Delivery time | Within 7-15 days after receive 30% deposit or as your requirement |

Stock | Ready in stocks |

What is stainless steel used for?

Stainless steels of various kinds are used in thousands of applications. The following gives

a flavour of the full range:

Domestic – cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

Architectural/Civil Engineering –cladding, handrails, door and window fittings, street furniture, structural sections, reinforcement bar,

lighting columns, lintels, masonry supports

Transport – exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

Chemical/Pharmaceutical – pressure vessels, process piping.

Oil and Gas – platform accommodation, cable trays, subsea pipelines.

Medical – Surgical instruments, surgical implants, MRI scanners.

Food and Drink – Catering equipment, brewing, distilling, food processing.

Water – Water and sewage treatment, water tubing, hot water tanks.

General – springs, fasteners (bolts, nuts and washers), wire.

Our Services

Stocks of stainless steel coil

| Stock Sizes | 0.3mmx1000mm / 1220mm / 1250mm 0.5mmx1000mm / 1220mm / 1250mm 0.8mmx1000mm / 1220mm / 1250mm 1.0mmx1000mm / 1220mm / 1250mm 1.2 mmx1000mm / 1220mm / 1250mm 1.5 mmx1000mm / 1220mm / 1250mm 2.0 mmx1000mm / 1220mm / 1250mm 2.5 mmx1000mm / 1220mm / 1250mm 3.0 mmx1000mm / 1220mm / 1250mm / 1500mm 4.0 mmx1000mm / 1220mm / 1250mm / 1500mm 5.0 mmx1000mm / 1220mm / 1250mm / 1500mm 6.0 mmx1000mm / 1220mm / 1250mm / 1500mm

|

Factory fecilities of stainless steel coil

Our company processing center is located in Tianjin.We have Nova cutting machine,

laser cutting machine,shearing machine,slitting machine,mirror polishing machine,

plate polishing machine,grinding machine,water jet cutting machine,red flower

machine,plasma cutting machine,large CNC milling machines,boring machines,

and many other processing equipment,we could provide a wide range of

personalized services according to customer needs.

Packaging & Shipping

5.Packaging--stainless steel coils

- Q: What is a stainless steel strip?

- A stainless steel strip is a thin, flat piece of stainless steel material that is typically manufactured in a continuous roll or coil form. It is commonly used in various industries due to its excellent corrosion resistance, strength, and durability. The strip is produced by cold rolling stainless steel sheets or coils to a precise thickness, resulting in a smooth and uniform surface. It can be further processed or fabricated into different forms, such as sheets, plates, or even precision components. Stainless steel strips find extensive applications in automotive, aerospace, construction, electronics, and many other sectors where high-quality and reliable materials are required.

- Q: Can stainless steel strips be used in chemical processing?

- Yes, stainless steel strips can be used in chemical processing. Stainless steel is known for its excellent corrosion resistance, making it suitable for various applications in the chemical industry. It is resistant to many aggressive chemicals, acids, and bases, and can withstand high temperatures and pressures. Stainless steel strips are commonly used in chemical processing equipment, such as reactors, heat exchangers, storage tanks, and piping systems. They provide durability, reliability, and long service life, making them a preferred choice for handling corrosive chemicals and maintaining product purity in chemical processing operations.

- Q: Are stainless steel strips suitable for HVAC systems?

- Yes, stainless steel strips are suitable for HVAC systems. Stainless steel is a corrosion-resistant material that can withstand the harsh environments and high temperatures commonly found in HVAC systems. It is durable, long-lasting, and provides excellent heat transfer properties. Stainless steel strips are often used for making ductwork, heat exchangers, and other components in HVAC systems due to their strength, resistance to corrosion, and ability to maintain cleanliness and hygiene. Additionally, stainless steel strips are easy to clean and maintain, making them a popular choice for HVAC applications.

- Q: Are stainless steel strips suitable for architectural facades?

- Yes, stainless steel strips are suitable for architectural facades. They offer a sleek and modern appearance, excellent durability, and resistance to corrosion, making them an ideal choice for both indoor and outdoor applications. Additionally, stainless steel can be easily manipulated into various shapes and sizes, allowing for creative and unique designs in architectural facades.

- Q: What are the factors affecting the electrical resistivity of 111 stainless steel strips?

- There are several factors that can affect the electrical resistivity of 111 stainless steel strips. 1) Composition: The chemical composition of the stainless steel, including the presence of various alloying elements, can have a significant impact on its electrical resistivity. Different alloying elements can alter the atomic structure and arrangement of the material, thus affecting the movement of electrons and the overall resistivity. 2) Temperature: The electrical resistivity of stainless steel can vary with changes in temperature. Generally, resistivity tends to increase with an increase in temperature due to the increased thermal vibrations of atoms, which hinder the flow of electrons. 3) Microstructure: The microstructure of the stainless steel, including factors such as grain size, grain boundaries, and dislocations, can influence its electrical resistivity. For instance, a smaller grain size can result in a higher resistivity due to increased grain boundary scattering of electrons. 4) Impurities and Defects: The presence of impurities and defects within the stainless steel structure can affect its resistivity. Impurities can create localized regions of different electrical properties, leading to variations in resistivity. Similarly, defects like dislocations can act as obstacles to the flow of electrons, increasing the resistivity. 5) Processing and Heat Treatment: The manufacturing process and subsequent heat treatment of stainless steel strips can affect their electrical resistivity. Factors such as cold working, annealing, and quenching can modify the microstructure and introduce changes in resistivity. 6) Magnetic Field: The application of a magnetic field can also influence the electrical resistivity of stainless steel. This phenomenon, known as the magnetoresistive effect, occurs due to the interaction between the magnetic field and the electrons in the material, altering their motion and resulting in changes in resistivity. Overall, the electrical resistivity of 111 stainless steel strips is determined by a combination of factors including composition, temperature, microstructure, impurities, processing, and the presence of a magnetic field. Understanding and controlling these factors is crucial for engineering and designing stainless steel strips with specific electrical resistivity properties.

- Q: Can stainless steel strips be heat treated?

- Yes, stainless steel strips can be heat treated. Heat treatment of stainless steel strips can help improve their mechanical properties, such as hardness and strength, as well as enhance their corrosion resistance. The specific heat treatment process and parameters may vary depending on the grade of stainless steel and the desired properties.

- Q: What are the different types of edges for stainless steel strips?

- Stainless steel strips can be manufactured with various types of edges, each serving a specific purpose and application. Some of the common types of edges for stainless steel strips include: 1. Mill Edge: This is the most common type of edge and is produced during the manufacturing process. It has a slightly rounded or curved edge, which is suitable for general applications. 2. Slit Edge: This edge is achieved by slitting the stainless steel strip into narrower widths. It is typically a straight edge, but it may have slight burrs or roughness. Slit edges are commonly used in industries where precision and tight tolerances are not critical. 3. Deburred Edge: To remove any burrs or roughness present on the slit edge, a deburring process is applied. This creates a smooth and rounded edge, ensuring safety and preventing damage during handling. 4. Rolled Edge: This edge is achieved by rolling the stainless steel strip, resulting in a smooth, rounded edge. Rolled edges are commonly used in applications where safety and aesthetics are important, such as in architectural and decorative applications. 5. Beveled Edge: A beveled edge refers to a sloping or angled cut made on the edge of the stainless steel strip. It is typically used in applications where welding or joining is required, as the bevel facilitates a better weld penetration and joint strength. 6. Sheared Edge: This type of edge is produced by shearing or cutting the stainless steel strip with a sharp blade. Sheared edges may have slight variations and irregularities but are suitable for applications where precision is not critical. 7. Custom Edges: Depending on specific requirements, stainless steel strips can be produced with custom edges. These edges are tailored to meet the unique needs of the application, such as special chamfers, grooves, or profiles. It is important to consider the intended use and requirements of the stainless steel strip when selecting the appropriate type of edge. The choice of edge can impact the strip's functionality, appearance, and compatibility with different manufacturing processes.

- Q: Can stainless steel strips be used in the aerospace manufacturing industry?

- Yes, stainless steel strips can be used in the aerospace manufacturing industry. Stainless steel strips possess excellent strength, corrosion resistance, and high-temperature resistance properties, making them suitable for various aerospace applications such as aircraft frames, structural components, engine parts, and fasteners.

- Q: Can stainless steel strips be used in chemical processing industries?

- Yes, stainless steel strips can be used in chemical processing industries. Stainless steel has excellent corrosion resistance, high strength, and durability, making it suitable for various chemical applications. It is commonly used in the construction of tanks, pipes, valves, and other equipment where it comes into contact with corrosive chemicals. Additionally, stainless steel's hygienic properties and easy cleanability make it a preferred choice in industries that require strict cleanliness and sterility standards, such as pharmaceutical and food processing.

- Q: Can 111 stainless steel strips be annealed for improved ductility?

- Indeed, it is possible to anneal a total of 111 stainless steel strips to enhance their ductility. Annealing entails subjecting the material to a precise temperature and subsequently gradually cooling it. This procedure serves to alleviate any internal tensions within the material and facilitates the reorganization of atoms, leading to increased ductility and decreased hardness. Through the annealing process, the stainless steel strips can acquire greater malleability and become more manageable, rendering them suitable for numerous applications that prioritize enhanced ductility.

Send your message to us

AISI304 201 316 321 430 stainless steel coil JIS EN DIN GB ASTM standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords