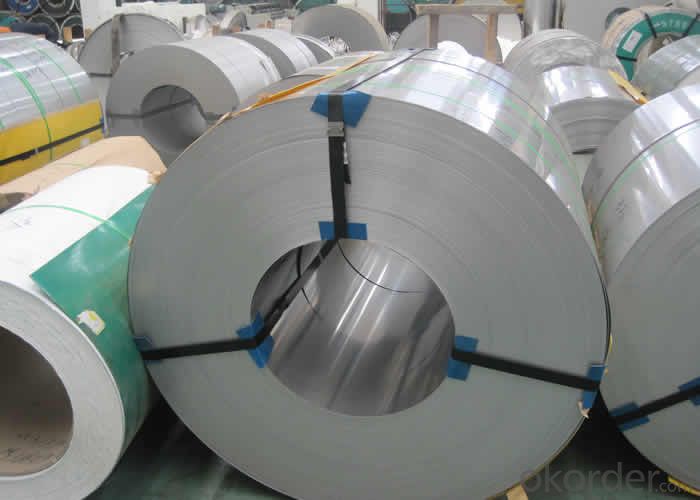

Stainless Steel Coil 304 Surface Finish No.1

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Grade: | 300 Series | Standard: | JIS,AISI,ASTM,GB,DIN,EN etc | Thickness: | 2.5mm, 3.0mm, 4.0mm |

Width: | 550mm-1500mm | Length: | according to weight | Place of Origin: | China (Mainland) |

Brand Name: | CNBM | Model Number: | 304 | Technique: | Hot Rolled |

Application: | industry, construction, furniture, repairing | Certification: | MTC | Finishing: | NO.1 |

Market: | globle area | Packaged: | wooden and bags in cases as standard | Payment: | TT & LC |

Delivery time: | 15 days | MOQ: | 100 tons | Advantage: | prime quality, competitive price |

Profession: | hot rolled | Charactor: | stainless steel coils | Material/Grade: | 304 |

Hot Rolled Stainless Steel Coil 304 Annealing and Pickling No.1 Finish

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

Hot Rolled Stainless Steel Coil 304 Specifications

1.surface:NO.1

2.standard:JIS, AISI, GB

3.width: 0.55m, 0.65m, 1.0m, 1.22m, 1.5m, 2m or requirement

Hot Rolled Stainless Steel Coil 304 Chemical Composition:

(%):C=0.07, Mn=2.00, P=0.045, S=0.030, Si=0.075, Cr=17.5-19.5, Ni=8.0-10.5, N=0.10

Hot Rolled Stainless Steel Coil 304 Physical Properties

Tensile strength σb (MPa) ≥ 520

the conditions yield strength σ0.2 (MPa) ≥ 205,

elongation δ5 (%) ≥ 40

Reduction of ψ (%) ≥ 50,

hardness: ≤ 187

HB; ≤ 90

HRB; ≤ 200H

Type | Hot Rolled Stainless Steel Coil 304 |

Thickness | 3.0mm-4.0mm |

Width | 550mm, 650mm, 1000mm, 1219mm, 1240mm, 1500mm |

Length | according to weight |

Brand name | CNBM |

Standard | ASTM, AISI, DIN, GB, JIS etc |

Material | 304 |

Application | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | Within 15 days since getting the deposit or LC origin |

Surface | NO.1 |

Productivity | 20000 tons/month |

- Q: Are stainless steel strips suitable for pharmaceutical equipment?

- Yes, stainless steel strips are suitable for pharmaceutical equipment. Stainless steel is highly resistant to corrosion, easy to clean, and has excellent durability, making it an ideal material for pharmaceutical equipment that requires high levels of cleanliness and hygiene. Additionally, stainless steel is non-reactive with most chemicals, ensuring the integrity and safety of pharmaceutical products.

- Q: Are stainless steel strips resistant to hydrogen embrittlement?

- Yes, stainless steel strips are generally resistant to hydrogen embrittlement due to their microstructure and high alloy content, which prevent hydrogen atoms from diffusing and causing embrittlement. However, certain factors such as high-strength grades or specific environmental conditions can still lead to hydrogen embrittlement in stainless steel strips.

- Q: Are stainless steel strips suitable for automotive fuel systems?

- Yes, stainless steel strips are suitable for automotive fuel systems. Stainless steel is known for its high corrosion resistance, making it an ideal choice for fuel systems in vehicles. It can withstand exposure to gasoline and other fuel types without corroding or degrading over time. Additionally, stainless steel's strength and durability ensure that it can withstand the high pressures and temperatures associated with automotive fuel systems. This material also has excellent heat resistance properties, which is crucial in preventing fuel leaks and maintaining the safety of the system. Furthermore, stainless steel strips can be easily formed and fabricated into various shapes and sizes, allowing for flexible design options in fuel system components. Overall, stainless steel strips offer the necessary qualities required for automotive fuel systems, making them a suitable choice for this application.

- Q: How do stainless steel strips perform in acidic environments?

- Stainless steel strips are highly resistant to corrosion in acidic environments due to the presence of chromium in its composition, which forms a protective oxide layer. This layer prevents the steel from reacting with acids, ensuring excellent performance and durability even in highly acidic conditions.

- Q: Are stainless steel strips suitable for chemical storage tanks?

- Yes, stainless steel strips are suitable for chemical storage tanks. Stainless steel is highly resistant to corrosion, making it ideal for storing chemicals that may be corrosive or reactive. It has excellent strength and durability, ensuring the tank can withstand the pressure and weight of the chemical contents. Additionally, stainless steel is non-porous, preventing the absorption of chemicals and avoiding contamination. It is also easy to clean and maintain, reducing the risk of cross-contamination between different chemicals. Overall, stainless steel strips provide a reliable and long-lasting solution for chemical storage tanks.

- Q: How do you join stainless steel strips together?

- Stainless steel strips can be joined together using various methods such as welding, soldering, or using mechanical fasteners such as screws or bolts. Welding is the most common and effective method, which involves melting the edges of the strips together to create a strong bond. Additionally, soldering can be used for thinner strips, where a filler metal is melted between the strips to join them. Mechanical fasteners provide a non-permanent solution and can be used when disassembly might be required.

- Q: Can stainless steel strips be used in architectural column systems?

- Yes, stainless steel strips can be used in architectural column systems. Stainless steel is a versatile material that offers several benefits for architectural applications. It is durable, corrosion-resistant, and has a sleek and modern appearance, making it an ideal choice for column systems in buildings. Stainless steel strips can be used to create decorative cladding or coverings for columns, providing an aesthetically pleasing and contemporary look. These strips can be easily shaped and formed to fit the design requirements of the column system, allowing for customized and unique architectural features. In addition to its visual appeal, stainless steel is also known for its strength and longevity. It can withstand various environmental conditions, including extreme temperatures, moisture, and UV exposure, without rusting or deteriorating. This makes stainless steel strips a reliable and low-maintenance option for architectural column systems, ensuring their longevity and durability. Furthermore, stainless steel is a sustainable material, as it is fully recyclable and can be reused or repurposed after its intended use. This aligns with the growing trend of incorporating sustainable and eco-friendly materials in architectural designs. Overall, stainless steel strips are a suitable choice for architectural column systems due to their durability, corrosion resistance, aesthetic appeal, and sustainability. Architects and designers can confidently use stainless steel strips to enhance the visual appearance and structural integrity of their column systems in various architectural projects.

- Q: Can stainless steel strips be used in architectural facades?

- Yes, stainless steel strips can be used in architectural facades. Stainless steel is a durable and versatile material that offers excellent resistance to corrosion, making it suitable for outdoor applications. Its sleek and modern appearance also adds aesthetic appeal to architectural designs.

- Q: What are the common methods of cutting stainless steel strips?

- The common methods of cutting stainless steel strips include using shears, power saws (such as band saws or circular saws), laser cutting, water jet cutting, and plasma cutting.

- Q: How do you prevent stress corrosion cracking of stainless steel strips?

- To prevent stress corrosion cracking of stainless steel strips, several measures can be taken. First, it is essential to ensure that the stainless steel is of high quality and has a suitable chemical composition. Next, controlling the environment in which the strips are exposed is crucial. This involves avoiding exposure to corrosive substances such as chlorides, acids, and alkalis. Additionally, maintaining appropriate levels of temperature and humidity can help minimize the risk. Proper cleaning and regular inspections also play a significant role in preventing stress corrosion cracking. Finally, applying protective coatings or using corrosion inhibitors can provide an extra layer of defense against this type of corrosion.

Send your message to us

Stainless Steel Coil 304 Surface Finish No.1

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords