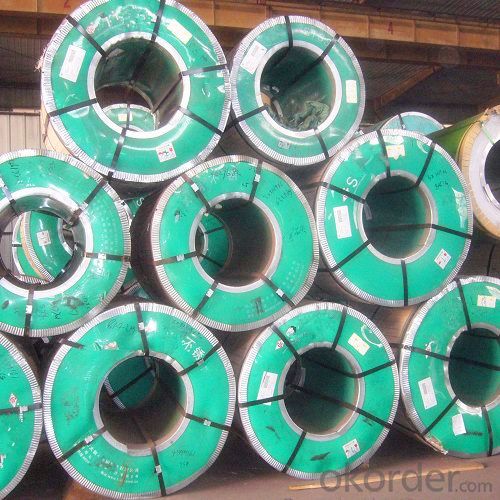

Hot Rolled Stainless Steel Coil 430 No.1 Finish

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Grade: | 400 Series | Standard: | JIS,AISI,ASTM,GB,DIN,EN | Length: | Coil |

Thickness: | 2.5mm,3.0mm, 4.0mm | Width: | 1000mm, 1219mm, 1240mm, 1500mm | Place of Origin: | China Mainland |

Brand Name: | CNBM | Model Number: | 430 | Type: | Coil |

Application: | Element Supports,Stove trim rings,Fasteners,Chimney Liners | Certification: | ISO | Certificate: | ISO9001:2008 |

Surface: | No.1 | Technique: | Hot Rolled | Experience: | About 20 years |

Stock Information: | In stock | Weight per coil: | 18-22 tons | Tolerance: | +/-0.1mm or less |

Model No.: | 430 |

|

|

|

|

Hot Rolled Stainless Steel Coil 430 No.1 Finish

Article | Hot Rolled Stainless Steel Coil 430R |

Grade | 400 series |

Specification | 1m, 1.2m, 1.5m |

Surface | No.1 |

Type | Sheet / Coil |

Width | 1000mm, 1219mm, 1240mm, 1500mm |

Thickness | 2.5mm,3.0mm, 4.0mm |

Brand name | CNBM |

Parking | seaworthy wooden pallets or wooden cases,in 20' or 40' container or as per customers' requirements |

Payment | 30% in advance,70% after shipping, or L/C at sight |

Delivery Time | Stock materials, within7-15 days after received the deposit of T/T or L/C |

Hot Rolled Stainless Steel Coil 430 No.1 Finish

Grade | C | Cr | Si | Mn | Mo | Ni | P | S |

| Max |

| Max | Max |

| Max | Max | Max |

430 | 0.12 | 16.0-18.0 | 0.75 | 1.00 | ----- | 0.6 | 0.04 | 0.03 |

- Q: What are the different types of finishes for stainless steel strips?

- Stainless steel strips offer a range of finishes, each with its own unique aesthetic and functional qualities. The most common finishes include: 1. No. 1 Finish, also known as hot rolled annealed and pickled (HRAP), involves annealing the strip and then pickling it to remove any roughness. This results in a dull, coarse surface. 2. No. 2B Finish, the most popular choice, features a smooth and reflective surface. It is achieved by cold rolling and annealing the strip, followed by a final light cold rolling pass for brightness. 3. No. 2D Finish is similar to No. 2B, but with a slightly duller and less reflective surface. This finish is obtained by cold rolling the strip to a thinner gauge. 4. No. 3 Finish, also known as a ground finish, is achieved by grinding the surface of the strip with increasingly finer abrasive materials. It creates a smooth, unidirectional grain pattern. 5. No. 4 Finish, a brushed or satin finish, provides a refined appearance. It involves mechanically polishing the strip with abrasive belts or brushes to create a consistent, fine-grained finish. 6. No. 5 Finish is similar to No. 4, but with a higher level of polish. It is achieved by using finer abrasives and additional polishing steps, resulting in a mirror-like, highly reflective surface. 7. BA (Bright Annealed) Finish is a mirror-like finish achieved by annealing the strip in a controlled atmosphere and then cold rolling it. It offers the highest level of reflectivity and is commonly used for decorative purposes. It's important to remember that the appearance and quality of these finishes may vary depending on the stainless steel grade and manufacturing process. The choice of finish depends on the intended application, desired aesthetics, and functional requirements of the strip.

- Q: Can stainless steel strips be used in the aerospace fasteners?

- Aerospace fasteners can indeed utilize stainless steel strips. Due to its exceptional resistance to corrosion, high strength-to-weight ratio, and ability to endure extreme temperatures, stainless steel is a frequently employed material in the aerospace sector. By shaping stainless steel strips into various forms and sizes, it becomes possible to fashion fasteners like screws, bolts, nuts, and rivets. These fasteners play a crucial role in connecting different aircraft components, ensuring both structural integrity and safety. Furthermore, stainless steel's non-magnetic properties make it a suitable option for applications where magnetic interference is a concern, such as avionics and electronic systems. All in all, stainless steel strips are a dependable and extensively used material for aerospace fasteners.

- Q: Can stainless steel strips be used for heat sinks?

- Yes, stainless steel strips can be used for heat sinks. Stainless steel has good thermal conductivity, which allows it to transfer heat efficiently. Additionally, stainless steel is resistant to corrosion, making it a durable option for heat sink applications. However, it is important to note that stainless steel has lower thermal conductivity compared to materials like copper or aluminum, which are commonly used for heat sinks. Therefore, stainless steel strips may not be as effective as other materials in dissipating heat in high-power applications.

- Q: What are the factors affecting the thermal expansion of 111 stainless steel strips?

- There are several factors that can affect the thermal expansion of 111 stainless steel strips. 1. Composition: The composition of the stainless steel, including the presence of alloying elements such as nickel and chromium, can impact its thermal expansion behavior. Different compositions can result in different rates of expansion when subjected to temperature changes. 2. Temperature range: The temperature range to which the stainless steel strips are exposed can significantly affect their thermal expansion. Higher temperatures generally cause materials to expand more, while lower temperatures can lead to contraction. The specific temperature range in which the strips are used or exposed will determine their thermal expansion characteristics. 3. Heat treatment: The heat treatment process applied to the stainless steel strips can also influence their thermal expansion. Various heat treatment methods, such as annealing or quenching, can alter the microstructure and crystal lattice of the steel, affecting its thermal expansion properties. 4. Grain size: The grain size of the stainless steel can impact its thermal expansion behavior. Smaller grain sizes generally result in lower thermal expansion coefficients, while larger grain sizes can lead to higher coefficients. The grain size can be influenced by factors such as the manufacturing process and heat treatment. 5. Surface finish: The surface finish of the stainless steel strips can affect their thermal expansion as well. Different surface finishes, such as polished or rough surfaces, can alter the thermal expansion characteristics by influencing the ability of the material to transfer heat. 6. Presence of impurities: The presence of impurities or foreign elements in the stainless steel can also affect its thermal expansion behavior. Impurities can disrupt the crystal lattice structure and introduce defects, which can impact the material's thermal expansion properties. 7. Mechanical stress: The presence of mechanical stress, either applied externally or generated internally due to manufacturing processes, can influence the thermal expansion behavior of the stainless steel strips. Mechanical stress can cause changes in the material's crystal structure and affect its ability to expand or contract uniformly. It is important to consider these factors when designing and selecting stainless steel strips for specific applications where thermal expansion characteristics are critical. By understanding and accounting for these factors, engineers can ensure that the stainless steel strips perform optimally under varying temperature conditions.

- Q: What are the common flatness tolerances for stainless steel strips?

- The common flatness tolerances for stainless steel strips typically range from 0.0015 to 0.003 inches per foot.

- Q: Can stainless steel strips be used for chemical reactors?

- Certainly! Chemical reactors can indeed utilize stainless steel strips. Stainless steel is widely preferred in the construction of chemical reactors owing to its exceptional resistance to corrosion, ability to withstand high temperatures, and overall durability. Its capacity to endure harsh chemical settings makes it an ideal choice for a diverse range of chemical reactions. When it comes to constructing reactors, stainless steel strips offer a flexible and economical solution as they can be effortlessly molded into desired configurations and dimensions. Additionally, stainless steel is simple to clean and maintain, guaranteeing the reactors' integrity while preventing any contamination during the chemical processes.

- Q: How do stainless steel strips resist erosion in abrasive environments?

- Stainless steel strips resist erosion in abrasive environments due to their unique composition and protective oxide layer. The high levels of chromium present in stainless steel form a passive film on the surface, which acts as a barrier against corrosion and prevents direct contact of the metal with the abrasive materials. This oxide layer is self-healing, meaning it can repair itself if damaged, further enhancing the steel's resistance to erosion. Additionally, stainless steel's high strength and hardness make it more resistant to wear and tear, allowing it to withstand the abrasive forces present in harsh environments.

- Q: What is the tensile strength of stainless steel strips?

- The tensile strength of stainless steel strips can vary depending on the specific grade and thickness of the material. However, stainless steel is known for its high tensile strength compared to other materials. On average, stainless steel strips have a tensile strength range of 515 to 2,000 megapascals (MPa). It is important to note that the tensile strength can also be influenced by factors such as the manufacturing process and any additional treatments applied to the stainless steel. Therefore, it is always advisable to refer to the specific technical data sheet or consult with a supplier to obtain accurate and detailed information about the tensile strength of a particular stainless steel strip.

- Q: What are the dimensions and thicknesses available for stainless steel strips?

- The dimensions and thicknesses available for stainless steel strips vary depending on the manufacturer and specific requirements. Common dimensions for stainless steel strips range from 0.1mm to 5mm in thickness and 10mm to 1000mm in width. However, it is important to note that there are numerous options available in the market to cater to different applications and customer needs.

- Q: Can 111 stainless steel strips be used in nuclear power plants?

- Yes, 111 stainless steel strips can be used in nuclear power plants. Stainless steel is commonly used in nuclear power plants due to its excellent corrosion resistance, high strength, and ability to withstand high temperatures. The specific grade, 111 stainless steel, may be suitable depending on the specific application and requirements within the nuclear power plant.

Send your message to us

Hot Rolled Stainless Steel Coil 430 No.1 Finish

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords