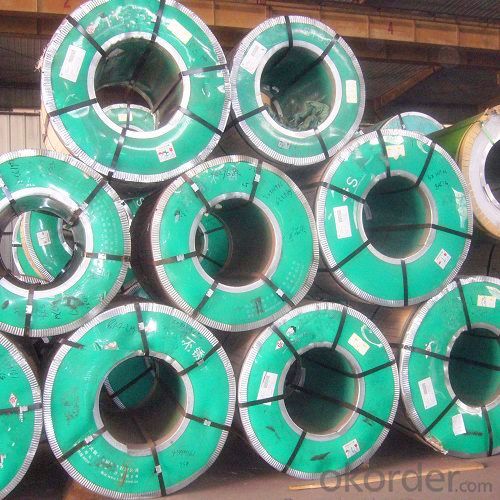

Hot Rolled Stainless Steel Coil 304 Narrow Strip No.1 Finish

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil 304 Annealing and Pickling No.1 Finish Narrow Strip

1.surface:NO.1

2.standard:JIS, AISI, GB

3.width: 0.55m

Hot Rolled Stainless Steel Coil 304 Chemical Composition:

(%):C=0.07, Mn=2.00, P=0.045, S=0.030, Si=0.075, Cr=17.5-19.5, Ni=8.0-10.5, N=0.10

Hot Rolled Stainless Steel Coil 304 Physical Properties

Tensile strength σb (MPa) ≥ 520

the conditions yield strength σ0.2 (MPa) ≥ 205,

elongation δ5 (%) ≥ 40

Reduction of ψ (%) ≥ 50,

hardness: ≤ 187

HB; ≤ 90

HRB; ≤ 200H

Type | Hot Rolled Stainless Steel Coil 304 |

Thickness | 3.0mm-4.0mm |

Width | 550mm |

Length | according to weight |

Brand name | CNBM |

Standard | ASTM, AISI, DIN, GB, JIS etc |

Material | 304 |

Application | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | Within 15 days since getting the deposit or LC origin |

Surface | NO.1 |

Productivity | 20000 tons/month |

Grade: | 300 Series | Standard: | JIS,AISI,ASTM,GB,DIN,EN etc | Thickness: | 2.5mm, 3.0mm, 4.0mm |

Width: | 550mm | Length: | according to weight | Place of Origin: | China (Mainland) |

Brand Name: | CNBM | Model Number: | 304 | Technique: | Hot Rolled |

Application: | industry, construction, furniture, repairing | Certification: | MTC | Finishing: | NO.1 |

Market: | globle area | Packaged: | wooden and bags in cases as standard | Payment: | TT & LC |

Delivery time: | 15 days | MOQ: | 100 tons | Advantage: | prime quality, competitive price |

Profession: | hot rolled | Charactor: | stainless steel coils | Material/Grade: | 304 |

- Q: What are the common length tolerances for stainless steel strips?

- The common length tolerances for stainless steel strips typically vary depending on the specific industry standards and requirements. However, common length tolerances for stainless steel strips can range from +/- 0.005 inches to +/- 0.030 inches, or even tighter tolerances depending on the precision needed for the application.

- Q: Can stainless steel strips be used in heat recovery systems?

- Indeed, heat recovery systems can make use of stainless steel strips. The reason behind stainless steel being a favored option for these systems lies in its remarkable resistance to corrosion and high temperatures. It is capable of enduring the elevated temperatures and challenging surroundings commonly encountered in heat recovery systems. Furthermore, stainless steel exhibits superior thermal conductivity, facilitating efficient heat transfer. Its robustness and durability render it a dependable choice for deployment in heat recovery systems, guaranteeing sustained effectiveness and minimal maintenance needs.

- Q: How do stainless steel strips perform in the presence of caustic solutions?

- In the presence of caustic solutions, stainless steel strips generally demonstrate good performance. This is due to the high chromium content in stainless steel, which provides it with a high level of resistance to corrosion and oxidation. As a result, stainless steel can withstand the harsh conditions typically found in caustic solutions. Additionally, stainless steel is renowned for its excellent chemical resistance, making it a suitable choice for applications involving caustic solutions. However, it is important to note that the performance of stainless steel strips may vary depending on the specific composition of the caustic solution and the duration of exposure. There are instances where prolonged exposure to highly concentrated or elevated temperature caustic solutions may cause localized corrosion or pitting on the surface of the stainless steel. Therefore, it is advisable to consult with experts or refer to technical specifications in order to determine the suitability of stainless steel strips for specific environments involving caustic solutions.

- Q: Can stainless steel strips be used in the automotive exhaust system industry?

- Yes, stainless steel strips can be used in the automotive exhaust system industry. Stainless steel is known for its high corrosion resistance and durability, making it an ideal material for exhaust systems that are exposed to extreme heat and various environmental conditions. Additionally, stainless steel strips can be easily formed and welded, making them suitable for manufacturing exhaust components such as pipes, mufflers, and catalytic converters.

- Q: What are the recommended safety precautions for handling 111 stainless steel strips?

- When handling 111 stainless steel strips, it is important to follow certain safety precautions to minimize the risk of accidents or injuries. Here are some recommended safety measures: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as gloves, safety glasses, and protective clothing, to protect yourself from potential hazards such as sharp edges or flying debris. 2. Proper Handling Techniques: Use proper lifting and handling techniques when dealing with stainless steel strips to prevent strain or back injuries. If the strips are heavy or bulky, consider using lifting equipment or asking for assistance. 3. Secure Storage: Store stainless steel strips in a secure and organized manner to prevent tripping hazards and ensure they do not fall and cause injuries. Use appropriate racks or shelves designed for storing metal strips. 4. Avoid Sharp Edges: Be cautious of the sharp edges commonly found on stainless steel strips. Handle them with care to avoid cuts or abrasions. Consider using gloves specifically designed for working with sharp-edged materials. 5. Fire Prevention: Stainless steel is non-combustible, but it can transfer heat effectively. Be cautious when handling hot strips or working in environments with open flames or sparks. Ensure fire prevention measures are in place, such as fire extinguishers and a clear evacuation plan. 6. Chemical Exposure: Some stainless steel strips might have been treated with chemicals or coatings. If you are unsure about the presence of any hazardous substances, consult the material safety data sheet (MSDS) or seek guidance from a supervisor or safety professional. 7. Proper Disposal: When disposing of stainless steel strips, follow local regulations and guidelines. Avoid throwing them in regular waste bins, as they can pose risks to sanitation workers or the environment. Consider recycling options or consult local authorities for proper disposal methods. Remember, these safety precautions are general guidelines, and it is important to consult specific safety instructions provided by the manufacturer or your employer.

- Q: Can 111 stainless steel strips be coated or plated for added protection?

- Yes, 111 stainless steel strips can be coated or plated for added protection.

- Q: What is the impact toughness after cryogenic treatment of stainless steel strips?

- The impact toughness of stainless steel strips is generally improved after cryogenic treatment. Cryogenic treatment involves subjecting the steel to extremely low temperatures, typically around -196°C (-321°F), to enhance its mechanical properties. This process causes a transformation of the steel's microstructure, resulting in increased hardness, strength, and resistance to wear. The impact toughness of a material refers to its ability to absorb energy and resist fracture under high-stress conditions. Cryogenic treatment helps to refine the microstructure of stainless steel, reducing the presence of brittle phases and improving its resistance to cracking or fracture when subjected to impact or high-stress situations. The low-temperature treatment also reduces residual stresses in the steel, which can further enhance its impact toughness. The reduction in residual stresses helps to improve the steel's ductility, making it less prone to sudden failure or fracture under impact or high-stress loads. Overall, the cryogenic treatment of stainless steel strips enhances their impact toughness, making them more suitable for applications that require high durability, resistance to cracking, and improved performance under impact or high-stress conditions.

- Q: Can stainless steel strips be used in food processing industries?

- Yes, stainless steel strips can be used in food processing industries. Stainless steel is highly resistant to corrosion, easy to clean, and has excellent hygiene properties, making it a preferred choice for equipment, machinery, and surfaces in food processing facilities.

- Q: Can stainless steel strips be heat resistant?

- Yes, stainless steel strips can be heat resistant. Stainless steel is known for its high resistance to heat and corrosion. Depending on the grade of stainless steel, it can withstand temperatures ranging from a few hundred degrees Celsius to over a thousand degrees Celsius. This makes stainless steel strips suitable for various applications where heat resistance is required, such as in automotive, aerospace, and industrial sectors. Additionally, stainless steel's heat resistance properties make it an ideal choice for cookware, oven components, and other household appliances that are exposed to high temperatures.

- Q: What type of stainless steel is magnetic stainless steel?

- Model with magnetic stainless steel: martensite or ferrite: such as 430, 420, 410 and so on, is magnetic.

Send your message to us

Hot Rolled Stainless Steel Coil 304 Narrow Strip No.1 Finish

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords