Hot Rolled Stainless Steel Coil 304 Narrow Strip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

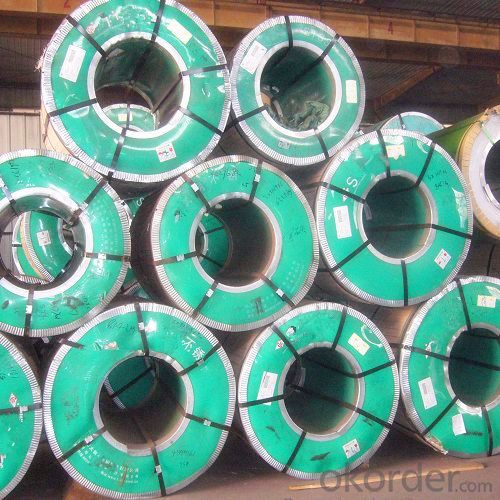

Hot Rolled Stainless Steel Coil 304 Narrow Strip

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.my company long-term

supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Specifications

1.surface:NO.1

2.standard:JIS, AISI, GB

3.width: 0.55m, 0.65m, 1.0m, 1.22m, 1.5m, 2.0m or requirement

ASTM 304

(%):C=0.07, Mn=2.00, P=0.045, S=0.030, Si=0.075, Cr=17.5-19.5, Ni=8.0-10.5, N=0.10

Physical Properties

Tensile strength σb (MPa) ≥ 520

the conditions yield strength σ0.2 (MPa) ≥ 205,

elongation δ5 (%) ≥ 40

Reduction of ψ (%) ≥ 50,

hardness: ≤ 187

HB; ≤ 90

HRB; ≤ 200H

Type | Hot Rolled Stainless Steel Coil 304 Narrow Strip |

Thickness | 2.5mm-4.0mm |

Width | 510mm, 550mm, 650mm |

Length | according to weight |

Brand name | CNBM |

Standard | ASTM, AISI, DIN, GB, JIS etc |

Material | 304 |

Application | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | Within 15 days since getting the deposit or LC origin |

Surface | NO.1 |

Productivity | 5000 tons/month |

- Q: Can stainless steel strips be used in musical instruments?

- Musical instruments can indeed utilize stainless steel strips. Stainless steel, a versatile and durable material, finds extensive use across multiple industries, including music. It boasts exceptional resistance to corrosion, high strength, and favorable mechanical properties, rendering it suitable for diverse musical instrument applications. Instruments such as guitars, pianos, drums, and other percussion instruments can incorporate stainless steel strips. For instance, stainless steel strips can serve as frets on guitars, delivering a smooth surface for the strings to facilitate clear and crisp sounds. Similarly, in pianos, they can function as keys or hammers, providing a consistent and reliable striking surface for the strings. Moreover, stainless steel strips can contribute to the construction of wind instruments. Brass instruments like trumpets or saxophones can incorporate stainless steel strips as reeds or valves. The corrosion resistance of stainless steel ensures durability and safeguards against moisture and saliva exposure during play, preventing deterioration. Overall, the utilization of stainless steel strips in musical instruments presents numerous advantages. They offer durability, corrosion resistance, and versatility, thereby ensuring optimal instrument performance and long-lasting quality.

- Q: Are stainless steel strips suitable for cryogenic applications?

- Indeed, cryogenic applications find stainless steel strips to be appropriate. Renowned for their remarkable mechanical properties, corrosion resistance, and thermal stability, stainless steel is favored across diverse sectors, particularly cryogenics. Stainless steel strips exhibit the capability to endure frigid temperatures sans compromising their structural integrity or succumbing to brittleness, an indispensable trait in cryogenic settings. Additionally, stainless steel boasts non-magnetic attributes and low thermal conductivity, both highly desirable in cryogenic applications that necessitate minimal heat transfer and magnetic interference. In summary, stainless steel strips emerge as a dependable and long-lasting choice for deployment within cryogenic applications.

- Q: What is the impact toughness after cryogenic treatment of stainless steel strips?

- The impact toughness of stainless steel strips is generally improved after cryogenic treatment. Cryogenic treatment involves subjecting the steel to extremely low temperatures, typically around -196°C (-321°F), to enhance its mechanical properties. This process causes a transformation of the steel's microstructure, resulting in increased hardness, strength, and resistance to wear. The impact toughness of a material refers to its ability to absorb energy and resist fracture under high-stress conditions. Cryogenic treatment helps to refine the microstructure of stainless steel, reducing the presence of brittle phases and improving its resistance to cracking or fracture when subjected to impact or high-stress situations. The low-temperature treatment also reduces residual stresses in the steel, which can further enhance its impact toughness. The reduction in residual stresses helps to improve the steel's ductility, making it less prone to sudden failure or fracture under impact or high-stress loads. Overall, the cryogenic treatment of stainless steel strips enhances their impact toughness, making them more suitable for applications that require high durability, resistance to cracking, and improved performance under impact or high-stress conditions.

- Q: How do stainless steel strips compare to other types of steel?

- Stainless steel strips have several advantages over other types of steel. Firstly, stainless steel is highly resistant to corrosion and rust due to the presence of chromium. This makes it ideal for applications where the steel will be exposed to moisture or harsh environments. In contrast, other types of steel may require additional coatings or treatments to achieve similar levels of corrosion resistance. Additionally, stainless steel strips have excellent strength and durability properties, making them suitable for a wide range of applications. They have a high tensile strength, which means they can withstand heavy loads without deforming or breaking. This makes stainless steel strips a popular choice for structural components in industries such as construction, automotive, and aerospace. Furthermore, stainless steel is known for its aesthetic appeal. It has a clean, shiny appearance that can be maintained even in harsh conditions. This makes stainless steel strips a preferred choice for applications where visual appeal is important, such as architectural and decorative purposes. Another advantage of stainless steel strips is their low maintenance requirements. They are relatively easy to clean and do not require regular painting or coating to maintain their appearance and durability. This can result in cost savings and reduced maintenance efforts compared to other types of steel. However, it is important to note that stainless steel strips may be more expensive initially compared to other types of steel. This is due to the higher production costs associated with the alloying elements, particularly chromium, which gives stainless steel its unique properties. Nonetheless, the long-term benefits and durability of stainless steel strips often outweigh the initial cost difference. Overall, stainless steel strips offer superior corrosion resistance, strength, durability, aesthetic appeal, and low maintenance requirements compared to other types of steel. These advantages make them a popular choice in various industries and applications.

- Q: What is the average lifespan of stainless steel strips?

- The average lifespan of stainless steel strips can vary depending on several factors, such as the grade and quality of the stainless steel, the environment in which the strips are used, and the level of maintenance and care they receive. In general, stainless steel is known for its durability and corrosion resistance, which can contribute to a longer lifespan compared to other materials. Stainless steel strips that are properly maintained and used in non-corrosive environments can last for several decades. However, if the strips are exposed to harsh chemicals, high temperatures, or abrasive conditions, their lifespan may be shortened. Regular cleaning and maintenance, such as removing any accumulated dirt or debris, can also help prolong the lifespan of stainless steel strips. It is important to note that the average lifespan is just an estimate and can vary depending on the specific application and usage conditions. If you are looking to use stainless steel strips for a specific project, it is recommended to consult with a professional who can provide more accurate information based on your specific requirements.

- Q: Are stainless steel strips suitable for jewelry making?

- Yes, stainless steel strips are suitable for jewelry making. Stainless steel is durable, resistant to tarnishing and corrosion, and has a sleek and modern look. It is also hypoallergenic, making it a great choice for those with sensitive skin. Additionally, stainless steel strips can be easily shaped and formed into various jewelry designs, making them versatile for creating unique and stylish pieces.

- Q: Can stainless steel strips be used in the construction industry?

- Yes, stainless steel strips can be used in the construction industry. Stainless steel is known for its high resistance to corrosion, durability, and strength, making it an ideal material for various construction applications. Stainless steel strips can be used for structural components, such as beams and columns, as well as for cladding, roofing, and facades. They are also commonly used for reinforcement purposes, such as in concrete structures or as support brackets. Additionally, stainless steel strips can be used in the construction of bridges, tunnels, and other infrastructure projects due to their ability to withstand harsh weather conditions and their low maintenance requirements. Overall, stainless steel strips offer numerous advantages in terms of longevity and aesthetic appeal, making them a popular choice in the construction industry.

- Q: Are stainless steel strips suitable for decorative embossing?

- Yes, stainless steel strips are suitable for decorative embossing. Stainless steel is a durable and versatile material that can be easily shaped and embossed to create intricate patterns and designs. It is often used in decorative applications such as architectural accents, signage, and artwork. The smooth and reflective surface of stainless steel also adds a sleek and modern aesthetic to any project. Additionally, stainless steel is resistant to corrosion and can withstand exposure to various weather conditions, making it a long-lasting option for decorative embossing.

- Q: Can stainless steel strips be used in the chemical manufacturing industry?

- Stainless steel strips have proven to be a valuable asset within the chemical manufacturing industry. This specific type of steel possesses exceptional corrosion resistance properties, making it an ideal option for environments where chemicals are prevalent. In the construction of chemical processing equipment, such as tanks, reactors, and piping systems, stainless steel strips are frequently utilized. The corrosion resistance of this material plays a crucial role in preventing any potential contamination of the chemicals being processed, thus ensuring the purity and integrity of the final product. Moreover, stainless steel strips exhibit remarkable resilience against high temperatures, enabling them to withstand the harsh conditions frequently encountered in chemical manufacturing processes. Furthermore, stainless steel boasts an advantage in terms of convenience, as it is easily cleaned and maintained. Consequently, this makes it a highly cost-effective and long-lasting choice for the chemical industry.

- Q: What is the difference between stainless steel strip and stainless steel sheet?

- The main difference between stainless steel strip and stainless steel sheet lies in their dimensions and applications. Stainless steel strip refers to a narrow, elongated piece of stainless steel with a consistent thickness, typically less than 6mm. It is commonly used in various industries such as automotive, electronics, and construction for manufacturing components like springs, clips, and connectors. On the other hand, stainless steel sheet is a flat, rectangular piece of stainless steel with a larger thickness, ranging from 6mm to several centimeters. It is often used in architectural, interior design, and industrial applications for cladding, countertops, and machinery parts.

Send your message to us

Hot Rolled Stainless Steel Coil 304 Narrow Strip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords