202 2B Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

202 Stainless Steel Sheet

1. Chemical composition

2.

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

max0.15 |

max1.00 |

7.50-10.50 |

max0.06 |

max0.03 |

4.00-6.00 |

17.00-19.00 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

245 |

590 |

40 |

218 |

95 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

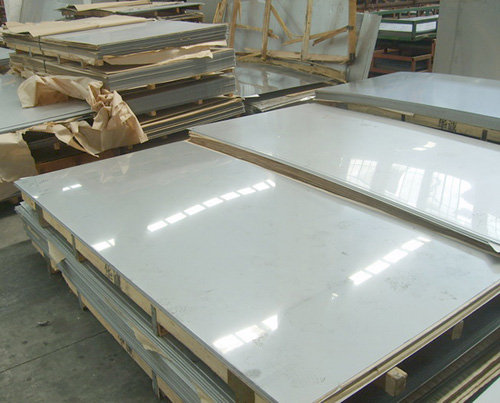

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q: Can stainless steel strips be used in the aerospace fasteners?

- Yes, stainless steel strips can be used in aerospace fasteners. Stainless steel is known for its corrosion resistance, strength, and durability, making it a suitable material for aerospace applications that require secure and reliable fastening.

- Q: How long do stainless steel strips last?

- Stainless steel strips have exceptional longevity and can last for decades or even a lifetime, as they are highly resistant to corrosion and wear.

- Q: Are stainless steel strips suitable for chemical reactors?

- Yes, stainless steel strips are suitable for chemical reactors. Stainless steel is known for its corrosion resistance, high temperature tolerance, and durability, making it a popular choice for various industrial applications, including chemical reactors. It can withstand the harsh chemical environments and provide long-lasting performance, making stainless steel strips a suitable material for use in chemical reactors.

- Q: What is the average lifespan of stainless steel strips?

- The average lifespan of stainless steel strips can vary depending on several factors, such as the grade and quality of the stainless steel, the environment in which the strips are used, and the level of maintenance and care they receive. In general, stainless steel is known for its durability and corrosion resistance, which can contribute to a longer lifespan compared to other materials. Stainless steel strips that are properly maintained and used in non-corrosive environments can last for several decades. However, if the strips are exposed to harsh chemicals, high temperatures, or abrasive conditions, their lifespan may be shortened. Regular cleaning and maintenance, such as removing any accumulated dirt or debris, can also help prolong the lifespan of stainless steel strips. It is important to note that the average lifespan is just an estimate and can vary depending on the specific application and usage conditions. If you are looking to use stainless steel strips for a specific project, it is recommended to consult with a professional who can provide more accurate information based on your specific requirements.

- Q: Can stainless steel strips be used in the nuclear industry?

- Yes, stainless steel strips can be used in the nuclear industry. Stainless steel is a popular material choice for various applications in the nuclear industry due to its excellent corrosion resistance and mechanical properties. It is commonly used in the construction of nuclear power plants, nuclear reactors, and related equipment. Stainless steel strips are used in the nuclear industry for a range of purposes. For instance, they can be used in the fabrication of nuclear fuel assemblies, which are crucial components of nuclear reactors. These fuel assemblies house the fuel rods that generate heat through nuclear fission. Stainless steel strips are used to provide structural support and ensure the integrity and safety of the fuel assemblies. Moreover, stainless steel strips are utilized in the construction of containment vessels and pressure vessels in nuclear plants. These vessels are responsible for containing radioactive materials and ensuring the safety of personnel and the surrounding environment. Stainless steel's resistance to corrosion and high-temperature environments makes it an ideal choice for these critical applications. Additionally, stainless steel strips are used in the manufacturing of various components such as piping systems, heat exchangers, valves, and pumps within nuclear facilities. These components require materials that can withstand harsh operating conditions, including high temperatures, radiation exposure, and corrosive environments. Stainless steel's durability and resistance to corrosion make it a reliable material for these applications. Overall, stainless steel strips are widely used in the nuclear industry due to their excellent properties, making them suitable for various applications. The industry relies on stainless steel's corrosion resistance, mechanical strength, and high-temperature tolerance to ensure the safety and efficiency of nuclear power generation.

- Q: Do stainless steel strips require any special handling or storage?

- Yes, stainless steel strips do require special handling and storage. They should be stored in a clean, dry, and well-ventilated area to prevent moisture buildup and corrosion. They should be handled with clean gloves to avoid contamination and should not be dragged or dropped to prevent damage. Additionally, stainless steel strips should be stored separately from other metals to prevent galvanic corrosion.

- Q: How do you clean stainless steel strips?

- To clean stainless steel strips, you can start by wiping them down with a soft cloth or sponge soaked in warm soapy water. For tougher stains or dirt buildup, you can use a non-abrasive cleaner specifically formulated for stainless steel. It's important to avoid using abrasive materials or harsh chemicals as they can damage the surface. After cleaning, make sure to rinse the strips thoroughly with water and dry them with a clean cloth to prevent water spots or streaks.

- Q: What is the hardness of stainless steel band 3/4?

- Hello, 3/4H stainless steel has too many materials, I don't know what kind of material you are talking about 301 and 304 are different. 3013/4H harder. 304 soft. And 201430, etc.... All different

- Q: How do stainless steel strips resist scaling?

- Due to the inclusion of chromium in their composition, stainless steel strips possess an inherent resistance to scaling. The chromium content within stainless steel produces a passive oxide layer on the surface, referred to as chromium oxide. This thin layer serves as a safeguarding barrier against oxidation, effectively preventing the metal from undergoing further reactions with environmental oxygen and thus deterring scaling. Furthermore, the incorporation of additional alloying elements like nickel and molybdenum boosts the corrosion resistance and scaling resistance attributes of stainless steel strips. The amalgamation of these elements results in the formation of a stable and long-lasting oxide layer, granting stainless steel remarkable resistance to scaling even when exposed to elevated temperatures.

- Q: Can stainless steel strips be used for wire mesh production?

- Yes, stainless steel strips can be used for wire mesh production.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

202 2B Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords