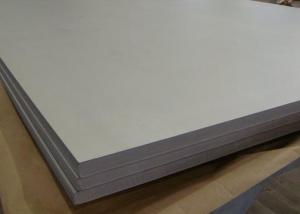

Stainless Steel Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 3500MT Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Are stainless steel strips suitable for elevator cabins?

- Yes, stainless steel strips are suitable for elevator cabins. Stainless steel is a popular choice for elevator cabins due to its durability, strength, and aesthetic appeal. It is resistant to corrosion, scratches, and stains, making it ideal for high-traffic areas like elevator cabins. Additionally, stainless steel is easy to clean and maintain, ensuring a hygienic environment for passengers. Its sleek and modern appearance also adds a touch of elegance to the overall design of the elevator. Overall, stainless steel strips are a reliable and stylish choice for elevator cabins.

- Q: How does stainless steel strip compare to other types of metal strips?

- Stainless steel strip is known for its exceptional corrosion resistance, high strength, and durability, which sets it apart from other types of metal strips. Unlike carbon steel or aluminum strips, stainless steel strip does not easily rust or stain, even in harsh environments. This property makes it ideal for applications where exposure to moisture, chemicals, or extreme temperatures is a concern. In terms of strength, stainless steel strip is often stronger than other metal strips, allowing it to withstand heavy loads and high stress applications. It also has excellent ductility, which means it can be easily formed and shaped into various configurations without losing its structural integrity. Another advantage of stainless steel strip is its aesthetic appeal. It has a sleek and polished appearance that is often desired in architectural, decorative, and industrial applications. Additionally, stainless steel strip is easy to clean and maintain, making it a popular choice in the food processing and medical industries where hygiene is critical. While stainless steel strip does have numerous advantages, it may not be suitable for every application. It tends to be more expensive compared to other metal strips such as carbon steel or aluminum. Additionally, stainless steel strip may have lower electrical and thermal conductivity compared to copper or other metals. Ultimately, the choice of metal strip material depends on the specific requirements of the application. Stainless steel strip is a preferred choice when corrosion resistance, strength, durability, and aesthetics are of utmost importance, but it is essential to consider other factors such as cost and conductivity when making a decision.

- Q: Do stainless steel strips require any special maintenance?

- Special maintenance is required for stainless steel strips. Although stainless steel is resistant to corrosion and staining, it is not completely immune to these problems. It is necessary to clean regularly in order to remove dirt, dust, and other substances that may potentially cause corrosion over time. To clean stainless steel strips, mild soap or detergent and warm water can be used, followed by rinsing and drying with a clean cloth. It is important to avoid using abrasive cleaners or materials that may scratch the surface of the stainless steel. Furthermore, it is recommended to refrain from using steel wool or other abrasive tools for cleaning. By performing regular maintenance and cleaning, the longevity and appearance of stainless steel strips can be ensured.

- Q: How do stainless steel strips resist stress corrosion cracking?

- Stainless steel strips resist stress corrosion cracking (SCC) due to their unique composition and properties. The primary factor that enables stainless steel to resist SCC is the presence of chromium. Chromium forms a passive oxide layer on the surface of the steel, which acts as a protective barrier against corrosive environments. This passive oxide layer, also known as the chromium oxide film, is self-repairing and continually forms even if it gets damaged or scratched. It effectively prevents the penetration of corrosive agents, such as chlorides, into the material, thereby inhibiting the initiation and propagation of stress corrosion cracking. Furthermore, stainless steel strips also contain nickel, molybdenum, and other alloying elements, which contribute to their enhanced resistance to SCC. Nickel improves the stability of the oxide layer and increases the overall resistance to corrosion. Molybdenum, on the other hand, enhances the material's resistance to pitting and crevice corrosion, which are often associated with SCC. The microstructure of stainless steel also plays a crucial role in its resistance to SCC. Stainless steel strips are typically engineered to have a fine-grained microstructure, which further enhances their resistance to corrosion. Fine grain size reduces the susceptibility to intergranular corrosion, a common precursor to stress corrosion cracking. In addition to the material composition, surface treatments and finishes can also contribute to the resistance against SCC. Passivation, pickling, or electropolishing processes can remove contaminants and enhance the formation of the protective oxide layer on the surface of the stainless steel strips. Overall, stainless steel strips resist stress corrosion cracking through the combined effects of the chromium oxide film, alloying elements, fine-grained microstructure, and appropriate surface treatments. These factors work together to provide excellent corrosion resistance, making stainless steel strips a reliable and durable material choice for various applications.

- Q: What is the difference between austenitic and martensitic stainless steel strips?

- Austenitic stainless steel strips have a face-centered cubic crystal structure, which provides high corrosion resistance, excellent formability, and good weldability. On the other hand, martensitic stainless steel strips have a body-centered cubic crystal structure, making them harder and more brittle than austenitic steel. Martensitic steel is known for its high strength and hardness, but it sacrifices some of the corrosion resistance and formability found in austenitic steel.

- Q: What are the factors affecting the creep resistance of 111 stainless steel strips?

- The factors affecting the creep resistance of 111 stainless steel strips can be numerous and include: 1. Composition: The chemical composition of the stainless steel strips, including the presence of alloying elements such as chromium, nickel, and molybdenum, can significantly impact its creep resistance. Higher levels of these elements generally improve resistance to creep deformation. 2. Microstructure: The microstructure of the stainless steel strips, including the size, distribution, and stability of the various phases and grain boundaries, can influence creep resistance. A fine and uniform grain structure with minimal grain boundary sliding is desirable for improved creep resistance. 3. Temperature: Creep resistance decreases as temperature increases. Higher temperatures promote the diffusion of atoms, resulting in increased creep deformation. Therefore, stainless steel strips intended for high-temperature applications should be designed to withstand the specific temperature range without significant creep deformation. 4. Stress level: The applied stress or load on the stainless steel strips can affect creep resistance. Higher stress levels can accelerate creep deformation, leading to reduced creep resistance. It is important to consider the stress levels that the strips will be subjected to during their intended service life. 5. Time: Creep resistance is time-dependent, meaning that the longer the stainless steel strips are subjected to a constant load or stress, the more susceptible they are to creep deformation. Therefore, the duration of the applied load or stress should be considered when assessing the creep resistance of 111 stainless steel strips. 6. Surface condition: The condition of the stainless steel strip's surface, including the presence of defects, scratches, or surface roughness, can influence its creep resistance. A smooth and defect-free surface can help minimize stress concentration and reduce the likelihood of localized creep deformation. 7. Environmental factors: The presence of aggressive environments, such as high-temperature gases or corrosive substances, can affect the creep resistance of stainless steel strips. Corrosion or oxidation can lead to the degradation of the material, reducing its creep resistance. 8. Heat treatment: The heat treatment process used during the manufacturing of stainless steel strips can significantly impact their microstructure and, consequently, their creep resistance. Proper heat treatment procedures, including annealing, quenching, and tempering, can optimize the material's creep resistance properties. It is important to note that these factors are interrelated and should be considered together when evaluating the creep resistance of 111 stainless steel strips.

- Q: Can stainless steel strips be bent or shaped?

- Yes, stainless steel strips can be bent or shaped. Stainless steel is a highly malleable material, meaning it can be easily manipulated into various forms and shapes. With the proper tools and techniques, stainless steel strips can be bent, curved, or formed into a desired shape. The bending or shaping process typically involves using specialized machines such as press brakes, rollers, or mandrels, which apply force to the stainless steel strip to achieve the desired shape. Additionally, the thickness and tempering of the stainless steel strip can also affect its bendability and shapeability. Overall, stainless steel strips offer a great amount of flexibility and can be easily manipulated to fit various applications and designs.

- Q: Are stainless steel strips suitable for automotive body panels?

- Yes, stainless steel strips are suitable for automotive body panels. Stainless steel has excellent corrosion resistance, durability, and aesthetic appeal, making it a popular choice for various automotive applications. It provides strength and can withstand harsh environmental conditions, ensuring the longevity and appearance of the vehicle's body panels.

- Q: What are the different types of stainless steel strips available?

- There are several different types of stainless steel strips available, including austenitic, ferritic, martensitic, and duplex stainless steel. Each type has its own unique properties and characteristics, making them suitable for various applications and industries.

- Q: Are stainless steel strips suitable for furnace parts?

- Indeed, furnace parts find stainless steel strips to be highly suitable. Renowned for its remarkable resistance to corrosion, heat, and oxidation, stainless steel emerges as an impeccable material for furnace components that endure extreme temperatures. These strips boast exceptional strength and durability, guaranteeing the endurance of furnace parts. Moreover, stainless steel's non-reactive properties render it compatible with diverse types of furnaces, spanning industrial, commercial, and residential applications. All in all, stainless steel strips stand as a dependable and effective option for furnace parts.

Send your message to us

Stainless Steel Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 3500MT Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords