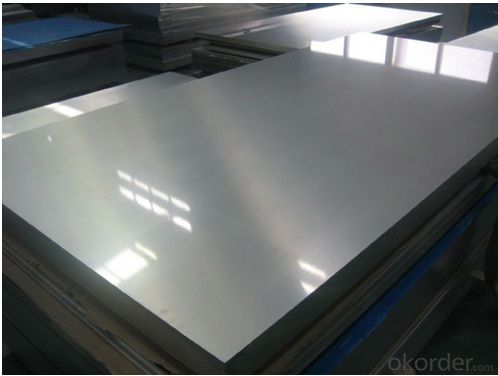

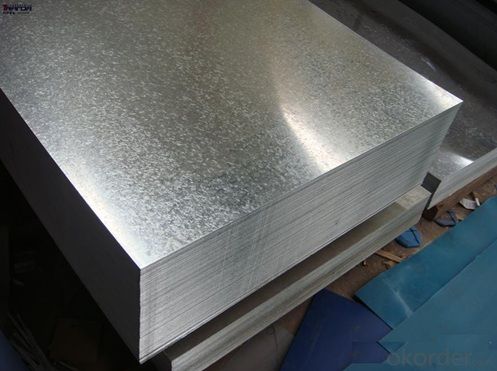

304 Stainless Steel Sheet & Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

304 Stainless Steel Sheet & Stainless Steel Plate

---Stainless steel plate applies to construction field, ships building industry, petroleum,

chemical industries, war and electricity industries, food processing and medical industry,

boiler heat exchanger,machinery and hardware fields.

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: 304/410/409/430/202/201

Thickness: 0.15mm~3.0mm,

Width: 1250,600-1250mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.160 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

1. How long will we receive the goods ?

45days after receiving workable L/C

1. how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: How do steel strips contribute to electrical conductivity in various applications?

- The high electrical conductivity properties of steel strips make them valuable in various applications where electrical conductivity is important. Steel, being a metal, contains a large number of free electrons that can move freely within its structure. This allows electric current to flow efficiently through the steel strips. In the realm of electrical applications, steel strips are widely used for manufacturing electrical conductors like wires and cables. The high electrical conductivity of steel strips ensures that electric current can easily pass through them with minimal resistance, resulting in efficient transmission of electrical power. Furthermore, steel strips are commonly utilized in the construction of electrical generators and transformers. These devices rely on the movement of magnetic fields to generate electricity or alter voltage levels. Due to their magnetic properties, steel strips help improve the efficiency of these devices by providing a path of low reluctance for the magnetic flux, thus enhancing overall electrical conductivity. Additionally, steel strips find applications in electrical grounding systems. Grounding is essential for electrical safety as it diverts excess electrical energy to the ground, preventing equipment damage and reducing the risk of electric shock. Steel strips used in grounding systems create a path of low resistance for the flow of fault currents, ensuring effective grounding and electrical conductivity. In conclusion, steel strips play a significant role in enhancing electrical conductivity in various applications. They possess high electrical conductivity, enabling efficient transmission of electrical power, enhancing the performance of electrical generators and transformers, and providing effective grounding solutions.

- Q: How are steel strips measured?

- Steel strips are typically measured by their thickness, width, and length using specialized instruments such as calipers, micrometers, or laser gauges.

- Q: Are steel strips prone to warping or distortion?

- Yes, steel strips are prone to warping or distortion under certain conditions.

- Q: How are steel strips processed for waterjet cutting?

- Steel strips are processed for waterjet cutting through a series of steps to ensure precision and accuracy. First, the steel strips are cleaned and prepared by removing any dirt, debris, or rust that may be present on the surface. This is done to ensure a clean and smooth cutting surface. Once the strips are cleaned, they are placed on a waterjet cutting machine. The machine is equipped with a high-pressure waterjet nozzle that shoots a stream of water mixed with an abrasive material, usually garnet, at extremely high speeds. This waterjet is capable of cutting through the steel strips with great precision. Before the actual cutting process begins, the waterjet cutting machine is programmed with specific cutting parameters. This includes the desired dimensions, shapes, and angles of the steel strips. The machine operator uses specialized software to input these parameters, which are then translated into instructions for the waterjet cutting machine. Once the cutting parameters are set, the machine operator starts the cutting process. The high-pressure waterjet is directed onto the steel strip, cutting through it with extreme accuracy. The waterjet can cut through various thicknesses of steel, ranging from thin strips to thicker plates, depending on the machine's capabilities. During the cutting process, the waterjet is constantly monitored to ensure the desired dimensions and shapes are being achieved. The machine operator may make adjustments to the cutting parameters if necessary to maintain accuracy. After the waterjet cutting is complete, the steel strips are carefully removed from the machine. They may undergo further processing, such as deburring or sanding, to ensure a smooth and finished edge. Overall, the process of waterjet cutting steel strips involves cleaning and preparing the strips, programming the cutting parameters, and using a high-pressure waterjet to precisely cut through the steel. This method is known for its accuracy, versatility, and ability to cut through various thicknesses of steel.

- Q: How are steel strips used in the production of electrical contacts?

- Steel strips are used in the production of electrical contacts as they provide the necessary strength and conductivity required for reliable electrical connections. These strips are typically made of high-quality steel alloys that offer excellent electrical conductivity while exhibiting good mechanical properties. The steel strips are first cut into precise dimensions and then undergo various manufacturing processes to shape them into the desired form of electrical contacts. They are often stamped or punched to create the required shape, such as flat or curved contacts. Once the contacts are formed, they are often plated or coated with a thin layer of precious metals like silver or gold. This plating enhances the electrical conductivity of the contacts and also provides corrosion resistance, ensuring long-term reliability of the electrical connections. Steel strips are also used as the base material for bimetallic contacts, which are commonly used in devices where temperature changes can affect the performance of electrical connections. Bimetallic contacts consist of two different metals bonded together, with one metal strip made of steel and another made of a material with a different coefficient of thermal expansion. This combination allows the contacts to expand and contract at different rates, ensuring reliable electrical connections even under varying temperature conditions. In summary, steel strips play a crucial role in the production of electrical contacts by providing the necessary strength, conductivity, and versatility required for various applications. Whether used as standalone contacts or as part of bimetallic structures, steel strips form the backbone of reliable electrical connections in a wide range of devices and systems.

- Q: What is the price of steel strips?

- The price of steel strips can vary depending on various factors such as the specific type of steel, the thickness and width of the strips, the quantity being purchased, and the current market conditions. It is best to consult with steel suppliers or manufacturers to get an accurate and up-to-date price quote for steel strips.

- Q: Are steel strips used in the production of medical instruments?

- Yes, steel strips are commonly used in the production of medical instruments. Steel strips are often used to construct various components of medical instruments such as surgical instruments, dental instruments, and diagnostic tools. The use of steel strips provides durability, strength, and corrosion resistance, making them suitable for medical applications.

- Q: How are steel strips processed for fastening?

- Steel strips undergo a series of steps to prepare them for various applications. It all begins by selecting high-quality steel, which is then rolled into thin strips of the desired thickness. These strips are cleaned through processes like degreasing or pickling to eliminate any impurities or contaminants. After the cleaning stage, the steel strips are annealed. This involves heating and slowly cooling them to relieve internal stresses and enhance their ductility. This makes the strips easier to work with and less likely to crack or break during fastening. Once annealed, the steel strips can be further treated based on specific requirements. For instance, they can be coated with protective layers, like zinc or galvanized coatings, to improve corrosion resistance. This is especially important for fastening applications where the strips will be exposed to harsh environmental conditions. To achieve the desired shape and dimensions, the steel strips are cut and shaped using methods like shearing, slitting, or stamping. These processes allow the strips to be tailored to the specific requirements of fastening, ensuring a precise fit and optimal performance. Finally, the processed steel strips are subject to quality control checks to ensure they meet the required standards. This involves testing for mechanical properties, dimensional accuracy, surface finish, and overall integrity. Overall, the processing of steel strips for fastening involves various steps, including cleaning, annealing, coating, shaping, and quality control measures. These steps ensure that the steel strips are well-prepared and suitable for a wide range of fastening applications, offering strength, durability, and reliability.

- Q: Are steel strips susceptible to magnetization?

- Yes, steel strips are susceptible to magnetization.

- Q: What are the common dimensions for steel strips?

- The common dimensions for steel strips vary depending on their intended use, but they typically range in thickness from 0.1mm to 5mm and in width from 10mm to 500mm. However, these dimensions can be customized to meet specific requirements in various industries.

Send your message to us

304 Stainless Steel Sheet & Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords