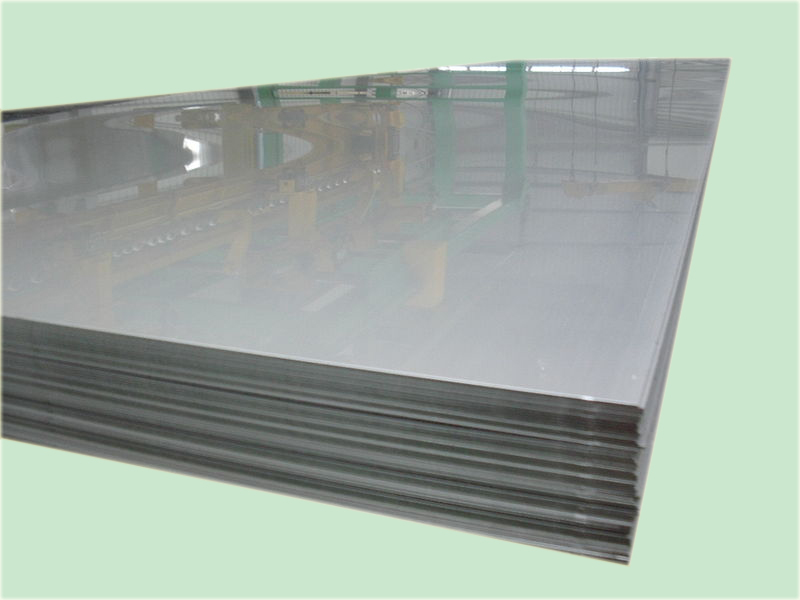

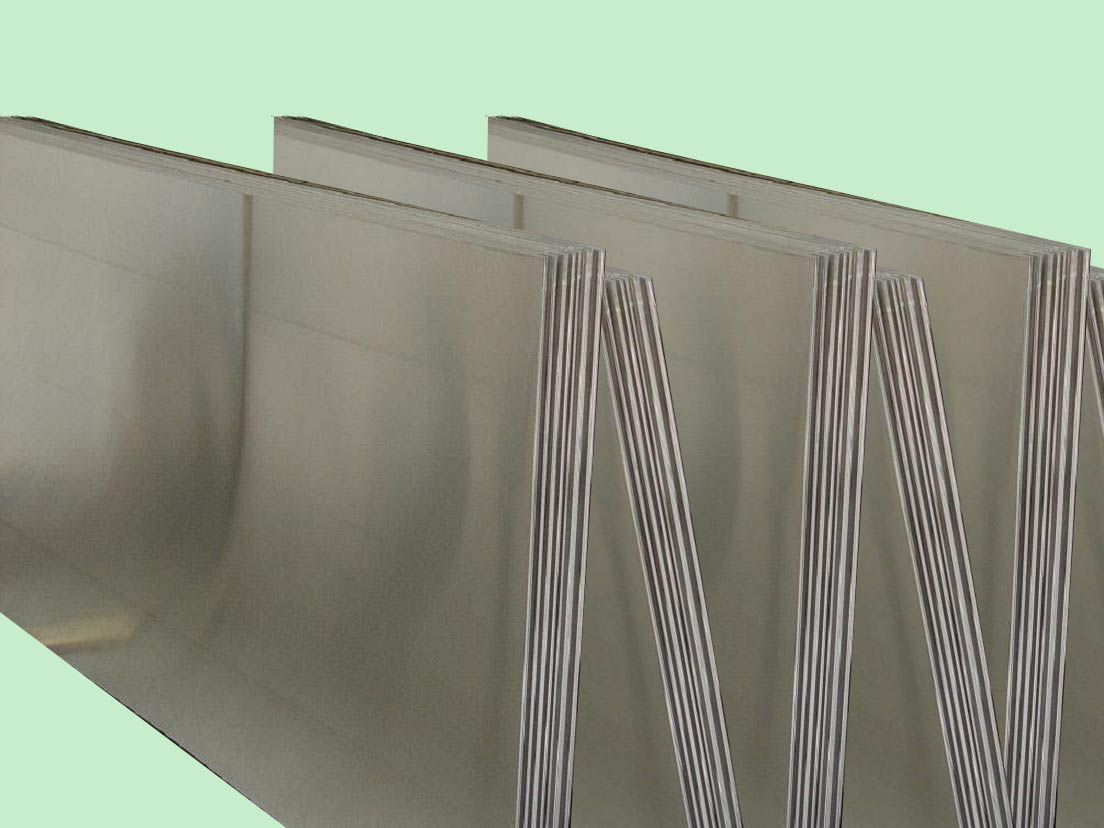

SUS304L stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

304L stainless Steel Sheet

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

Max0.03 |

Max1.00 |

Max2.00 |

Max0.045 |

Max0.03 |

9.0-13.0 |

18.0-20.0 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥175 |

≥480 |

≥40 |

≤200 |

≤90 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q: Are stainless steel strips suitable for decorative trim?

- Stainless steel strips are indeed appropriate for decorative trim. This versatile material boasts a sleek and modern aesthetic, which explains its popularity in decorative applications. Its polished and reflective surface adds a touch of sophistication and elegance to any space. Moreover, stainless steel strips are known for their durability, corrosion resistance, and easy maintenance, making them perfect for low-maintenance areas. They can be utilized in various settings such as kitchens, bathrooms, and commercial spaces to create a contemporary and stylish atmosphere. Furthermore, stainless steel strips offer endless design possibilities as they can be easily customized and fabricated into different shapes and sizes. In conclusion, stainless steel strips are an excellent choice for enhancing the decorative aspect of any interior or exterior space.

- Q: What are the main stainless steel belt used in the industry and products?

- This is the fastest growing area of stainless steel applications. The use of high strength stainless steel car body structure can greatly reduce the weight of the car, and enhance the strength of the body structure, using stainless steel as vehicle panels and decorative parts, can reduce maintenance costs.The problem of water pollution during storage and transportation has been paid more and more attention. A great deal of practice has proved that stainless steel is the best choice for water preparation, storage, transportation, purification, regeneration, desalination and other water industry. The advantages are: corrosion resistance, earthquake resistance, water saving, sanitation (no rust and copper green), light weight (reduced 1/3), Shao Weixiu, long life (40 years service), life cycle cost (LCC) is low, Recyclable using green materials.

- Q: Are stainless steel strips resistant to hydrogen embrittlement?

- Yes, stainless steel strips are generally resistant to hydrogen embrittlement. Stainless steel is known for its excellent corrosion resistance, and this property also extends to its resistance against hydrogen embrittlement. Hydrogen embrittlement is a phenomenon where hydrogen atoms penetrate the steel's crystal lattice, causing it to become brittle and susceptible to cracking or failure. However, stainless steel contains a high amount of chromium, which forms a passive oxide layer on its surface. This oxide layer acts as a protective barrier, preventing hydrogen atoms from diffusing into the steel and reducing the risk of embrittlement. Additionally, stainless steel strips are often made with austenitic grades, which have a high nickel content that further enhances their resistance to hydrogen embrittlement.

- Q: Are stainless steel strips recyclable?

- Yes, stainless steel strips are recyclable. Stainless steel is a highly recyclable material and can be reused to manufacture new products.

- Q: What is the magnetic permeability of stainless steel strips?

- The magnetic permeability of stainless steel strips can vary depending on the specific grade and composition of the stainless steel. Generally, stainless steel is considered to have a low magnetic permeability, meaning it is not very responsive to magnetic fields. This is due to the presence of chromium, which forms a thin oxide layer on the surface of the stainless steel, reducing its magnetic properties. However, some stainless steel grades, such as 430 and 446, can exhibit slightly higher magnetic permeability compared to others. In summary, while stainless steel is not typically considered to be strongly magnetic, the exact magnetic permeability of stainless steel strips will depend on the specific grade and composition.

- Q: Can stainless steel strips be used in the food processing equipment industry?

- Yes, stainless steel strips can be used in the food processing equipment industry. Stainless steel is highly resistant to corrosion, easy to clean, and has excellent hygienic properties, making it suitable for use in food processing equipment. It is commonly used for manufacturing food handling and preparation equipment, such as conveyor belts, cutting blades, mixing tanks, and storage containers.

- Q: Can stainless steel strips be used in the automotive industry?

- The automotive industry can make use of stainless steel strips, which are versatile and durable. Stainless steel is a material that offers numerous advantages for automotive applications. It possesses excellent corrosion resistance, making it capable of withstanding harsh environmental conditions and exposure to road salts or chemicals. Moreover, stainless steel strips are resistant to heat and can endure high temperatures, making them suitable for various automotive components like exhaust systems and engine parts. Additionally, they possess high strength and can provide structural support and reinforcement for automotive frames and body panels. Furthermore, they can be utilized for decorative purposes, enhancing the aesthetic appeal of vehicles. All in all, stainless steel strips are a dependable and valuable material choice for the automotive industry.

- Q: What are the factors affecting the strength of 111 stainless steel strips?

- The strength of 111 stainless steel strips can be influenced by various factors. These factors include the composition of the steel, the heat treatment process, the amount of cold working applied, the grain size, the surface finish, the environmental conditions, the manufacturing process, and the design considerations. Regarding composition, the strength of the steel can be greatly impacted by the chemical composition, particularly the levels of elements such as nickel, chromium, and molybdenum. Higher amounts of these elements generally result in increased strength. The heat treatment process used during manufacturing is another significant factor. Annealing, quenching, and tempering can alter the microstructure of the steel, leading to changes in strength. The amount of cold working or deformation applied to the steel during processing is also important. Cold working can enhance strength by introducing dislocations, but excessive cold working can cause brittleness. The grain size of the steel is another influential factor. Smaller grain sizes tend to result in higher strength due to increased grain boundaries, which hinder dislocation movement. The surface finish of the steel can affect its strength, particularly in terms of fatigue resistance. Smooth and polished surfaces tend to improve the material's fatigue strength. The environment in which the steel is used can impact its strength as well. Factors such as temperature, humidity, and exposure to corrosive substances can lead to degradation and reduced strength over time. The specific manufacturing process employed can also influence the strength of the steel. Variables such as rolling techniques, annealing processes, and cold reduction methods can all have an impact. The design of the steel, including factors like thickness, width, and the presence of surface defects or notches, can also affect strength. Proper design considerations should be made to ensure optimal strength and performance. It is important to note that these factors are interconnected, and changes in one factor can influence the others. Manufacturers and engineers must carefully consider all these factors to achieve the desired strength and performance of 111 stainless steel strips.

- Q: What are the common thicknesses available for stainless steel strips?

- The specific requirements and applications determine the varying common thicknesses of stainless steel strips. In the market, one can commonly find thicknesses like 0.2mm, 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, and 3.0mm. These thicknesses serve various purposes including the production of appliance components, automotive parts, construction materials, and numerous industrial applications. One must note that these thicknesses can differ among suppliers and manufacturers. Hence, it is advisable to verify the availability of the desired thickness with the specific supplier.

- Q: Can stainless steel strips be used in the oil refinery equipment?

- Yes, stainless steel strips can be used in oil refinery equipment. Stainless steel is highly resistant to corrosion and high temperatures, making it suitable for use in the harsh conditions of an oil refinery. It has excellent strength and durability, which allows it to withstand the corrosive and abrasive nature of oil refining processes. Additionally, stainless steel strips can be easily formed and fabricated into various shapes and sizes required for oil refinery equipment.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

SUS304L stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords