Aluminum On Stainless Steel

Aluminum On Stainless Steel Related Searches

Stainless Steel Aluminum Stainless Steel To Aluminum Stainless Steel Or Aluminum Acetone On Stainless Steel Sublimation On Stainless Steel Chromium In Stainless Steel Annealing Stainless Steel Anodizing Stainless Steel Sublimating On Stainless Steel Painting On Stainless Steel Vinegar On Stainless Steel Sublimate On Stainless Steel Mold On Stainless Steel Magnets On Stainless Steel Anodized Stainless Steel Acid Stains On Stainless Steel Stainless Steel Metals Glue To Stainless Steel Annealed Stainless Steel Metal Stainless Steel Stainless Steel Elements Rust On Stainless Steel Magnet On Stainless Steel Stick On Aluminum Diamond Plate Aluminum Metal Plate Stainless Steel Alloys Metals Stainless Steel Steel Wool On Stainless Steel Painting Of Stainless Steel Painting Stainless SteelAluminum On Stainless Steel Supplier & Manufacturer from China

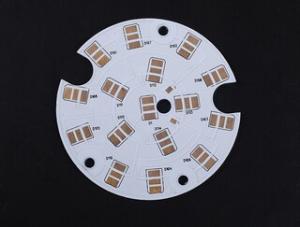

Aluminum on Stainless Steel is a composite material that combines the properties of aluminum with the strength and corrosion resistance of stainless steel. This unique combination results in a product that is both lightweight and durable, making it suitable for a wide range of applications. The fusion of these two materials provides a cost-effective solution for industries that require high-performance materials without compromising on quality.Aluminum on Stainless Steel is widely used in various industries, including automotive, aerospace, construction, and electronics. Its versatility allows it to be employed in applications such as heat sinks, radiators, and heat exchangers, where efficient heat dissipation is crucial. Additionally, it is used in structural components, decorative panels, and various other applications where both strength and light weight are essential. The product's ability to withstand harsh environments and resist corrosion makes it a popular choice for outdoor and marine applications as well.

Okorder.com is a leading wholesale supplier of Aluminum on Stainless Steel, offering a vast inventory of this high-quality material. With a commitment to customer satisfaction and a focus on providing reliable products, Okorder.com ensures that customers receive the best possible service and support. By partnering with Okorder.com, businesses can access a wide range of Aluminum on Stainless Steel products, ensuring that their projects and applications benefit from the superior performance and durability that this composite material offers.

Hot Products