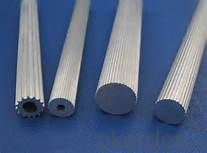

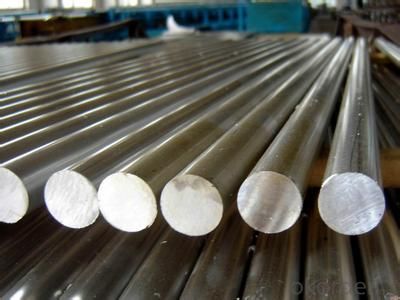

Aluminum rod

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Weare the largest aluminum profile manufacture in

The detail descriptions ofaluminum profile as bellowing:

Material | Alloy Aluminum 2xxx series, 6xxx series,7xxx series or customer nominated |

Temper | -- |

Surface | Mill |

| Size | According to the drawings |

Length | Not more than 12 meters |

Good Package | Standard packing |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

- Q: How to deal with the burning of 6061 aluminum bars in hard oxidation?

- Small spots appear in the anodic oxide film on the spot, after the dissolution and loss gradually expanded around. Overheating may be due to the electrical contact area is not enough, the distance between cathode and anode too close, mixing insufficient or incomplete mixing caused by uneven temperature in sulfuric acid electrolyte of aluminum content is too high.

- Q: What's the effect of manganese on aluminum bars?

- Al-Mn alloy flat part in the equilibrium phase diagram of the eutectic temperature of 658, manganese in solid solution in the body for the maximum solubility strength of 1.82%. alloy increased with the increasing solubility, manganese content is 0.8%, the elongation rate reached the maximum value of.Al-Mn alloy is non hardening alloy that can be strengthened by heat treatment.

- Q: Negative effects of zinc on aluminum bars

- The equilibrium phase diagram of Al-Zn alloy shows that the solubility of zinc in aluminium is 31.6%, while the solubility of aluminum decreases to 5.6% at 125 when the rich aluminum fraction reaches 275.When zinc is added to aluminum alone, the strength of aluminum alloy increases very much under the condition of deformation, and the tendency of stress corrosion cracking exists at the same time, which limits its application.The addition of zinc and magnesium to aluminum forms a strengthening phase, Mg/Zn2, which has an obvious strengthening effect on the alloy.

- Q: How does an ordinary lathe do a tensile test? A round aluminum bar

- full grading test optional speed; group sample statistical analysis calculation, curve superposition analysis, tensile stress;Power down memory, overload protection, etc.

- Q: Aluminum bar flaw detector which good?

- Consider Suzhou diamond electronic technology limited company, engaged in the series of eddy current flaw detector, sorting instrument, ultrasonic flaw detector, tube bar, metal parts, auto parts R & D automatic flaw detection system of production, provide a complete detection method and process of product quality to meet user requirements to improve the quality of all the rapid detection for customers, products widely for electric power, aerospace, military industry, metallurgy, 112379.jpg machinery manufacturing industry. Especially in the pipe, rod, wire and other metal parts, auto parts nondestructive testing in the leading position in china.

- Q: What material is produced by electrolytic water experiment of aluminum rods of iron rods?

- When the aluminum rod is used as the anode of the power supply, the negative pole of the iron rod is connected with the cathode of the power supply as the cathodeBecause aluminum is a living metal, aluminum will lose electrons as an anodeThe anodic reaction leads to the loss of aluminum to trivalent aluminiumThe cathode react with hydrogen ions to change electrons into hydrogenIf water is to be produced by electrolysis of water, oxygen should be used as anode and the cathode material connected to the negative electrode of the power supply does not matterI hope my answer will be helpful to you

- Q: How to calculate the length of aluminium alloy by extrusion machine?

- Extrusion = (actual length / upsetting coefficient excess pressure) * extrusion coefficientExtrusion factor = extrusion barrel area / finished cross section areaMaterial length = number of nodes x fixed lengthEnd = extrusion lengthBar length = ((number of nodes x fixed length + cut end) / extrusion coefficient + residual pressure) * upsetting coefficient

- Q: Can aluminum rod heating furnace be free of exhaust gas and no exhaust?

- Heating by electricity can be, but that kind of calculation has not been seen, generally burning coal and burning gas, if burning coal and burning gas, there must be exhaust exhaust areas, mainly carbon dioxide and sulfur and dust

- Q: Which material is hard, 7075 aluminum bar or 6065 aluminum bar?

- The hardness of 7075 aluminum bars is higher than 6065 aluminum bars

- Q: Is it 76012000, 76042900 or 7604291010? Thank you very much! Urgently!! FiveIs it 76012000, 76042900 or 7604291010? Thank you According to our engineers might be unwrought Aluminum Alloy, but from the cylindrical shape should be cylindrical solid Aluminum Alloy, the two different export tariffs, were 0 and 15, we export alloy ingots are written Aluminum Alloy unwrought aluminum bar, whether can also write this? In fact, these two processes are the same. Thank you for your advice, thank you! Urgently!!!

- Only at 76012000 and 7604291010, which should be forged;Personally think it should be the first 76012000

Send your message to us

Aluminum rod

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords