AA1XXX Mill-Finished C.C Aluminum Bars for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction Description

AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction Description is cut from aluminum coils 1xxx. The aluminum content of aluminum sheets 1xxx C.C quality is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

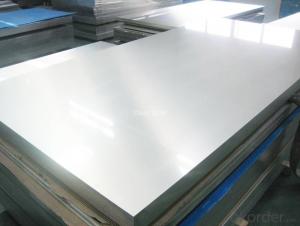

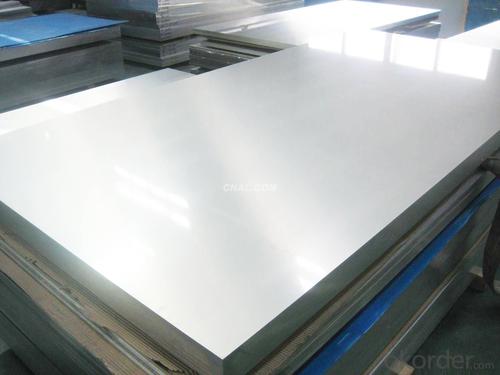

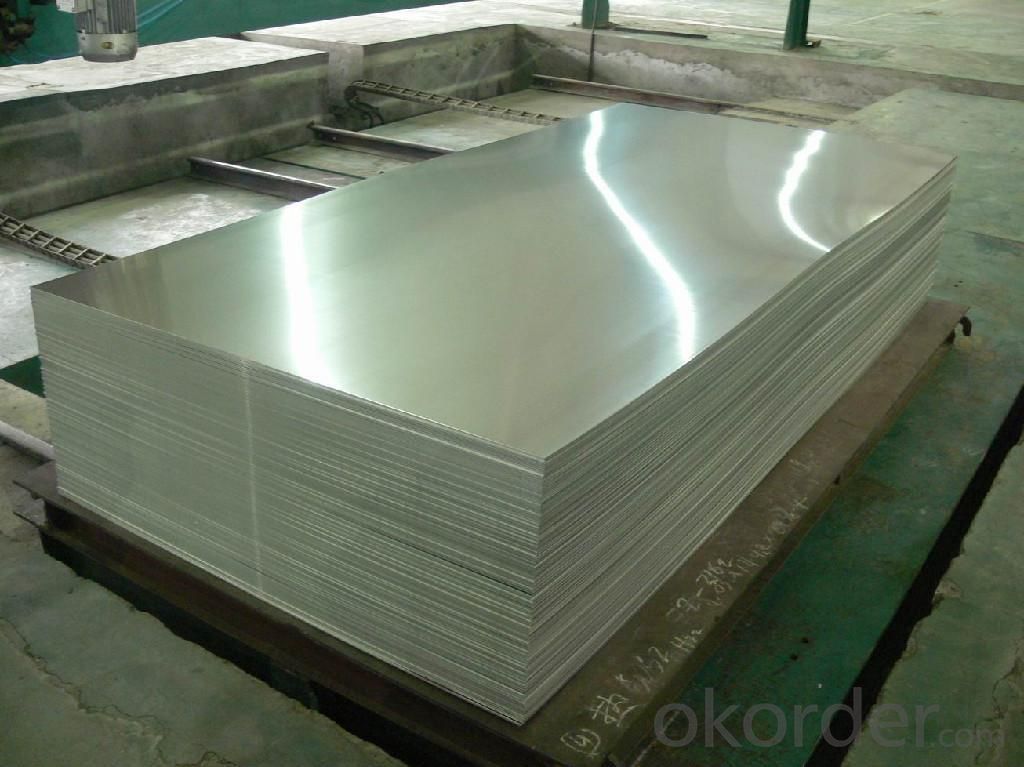

3.AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction Images

4.AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction Specification

Alloy | AA1xxx |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction.

B.When will you deliver the products?

AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Influence of cooling water temperature on surface segregation layer of aluminum rod

- Why not shiny aluminum rod: rust generated three two aluminum oxide (Al2O3) removal method: three oxidation reaction of two aluminum material with 1 examples: sodium hydroxide (NaOH) 1, three two aluminum oxide and sodium hydroxide, aluminum hydroxide, aluminum hydroxide 2 generation 3 heating decomposition example 2: low concentration of dilute salt acid solution (HCL) 1 such as, alumina leaching dilute hydrochloric acid in low concentration.

- Q: such as squatting, forging, swing, roll, spinning, heat treatment and mechanical processingForged wheels is a heating temperature of 460 degrees in the aluminum rod by high-end technology after the squat swinging, spinning, forging, heat treatment and mechanical processing, forging Aluminum Alloy wheel through the inspection and the resulting coating. Share with you, where there is no room for supplementation

- Look, you can't change it this way:The hub is a kind of precision forging, precision forging, the aluminum bar heating by high-end technology spinning, heat treatment and NC machining, and then after the product inspection process to eliminate defects strictly, finally produce high quality precision forging Aluminum Alloy hub.

- Q: Why is the 6063 aluminum bar not shiny?

- The aluminum rod surface is oxidized, polished aluminum, light, in the air will be oxidized, luster degree decreased gradually. In the liquid oxidation method can uniformly, forming a layer of aluminum oxide protective film. After processing or a layer of wax or varnish to protect.

- Q: Automatic blanking (formerly under copper machine)

- Clip the aluminum bits out with the pliers. The number of saw teeth should be 60 red or 50 red, and you must cut the aluminum bar with sparse teeth. Too close will stick. I've been in the cutting industry for 8 years.

- Q: What's the difference between cast aluminum bars and extruded aluminum bars?

- Production process of standard extruded aluminium barsThe aluminum bar production line can be divided into casting workshop, mould workshop, extruding workshop (1) / (two), aging workshop and packing workshopWarehouse and aluminium bar warehouse. The company's general production process is: casting workshop, aluminium bar warehouse, extrusion workshop, aging workshop, packingWarehouse to finished warehouseThe following analysis focuses on the casting workshop, extrusion workshop and Aging Workshop. (1) the casting processThe final purpose of casting process is the production to meet the requirements of the aluminum rod, and to produce the aluminum rod, to go through the process of melting, casting, cutting bar, aluminum rod casting workshop process of smelting process, uniform cooling, washing bar, aluminum rod into the warehouse,.

- Q: What can make the aluminum bar surface shiny?

- Aluminum is more complex. Aluminum itself is soft. Hand polishing is difficult to reach the mirror surface. Generally, the grinding force of the machine at high speed is used to reach the mirror surface

- Q: A man standing on an aluminum ladder and hitting a high tension wire with aluminum bars, will he be in danger?

- If the foot is an aluminum ladder, line to touch 0.4kV voltage or zero line is not electrified, but if it is hit more than 1kV high voltage, is dangerous, the basic insulation aluminum ladder has no effect on high voltage, if to touch the high voltage and high voltage is equal to the to the earth to form a loop, this is very dangerous.

- Q: Does the aluminum bar react with washing powder?

- No chemical reaction, because the main components of washing powder is twelve sodium, with good detergency, and very easy to use, so loved by the people.

- Q: Where are aluminum bars used mainly? What if the process is used?

- Generally used in the case of lower strength than steel, the main parts are shaft, pipe, flange parts, the main processing methods for the car, milling processing!

Send your message to us

AA1XXX Mill-Finished C.C Aluminum Bars for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches