One Up Aluminum Bars - AA1100 C.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

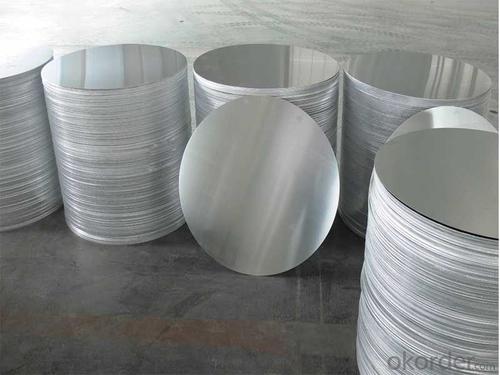

1.Structure of AA1100 C.C Mill Finished Aluminum Circles used for Cookware Description

AA1100 C.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1100 C.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1100 C.C Mill Finished Aluminum Circles used for Cookware

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

3.AA1100 C.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1100 C.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1100 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1100 C.C Mill Finished Aluminum Circles used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

How to guarantee the quality?

---Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1100 C.C Mill Finished Aluminum Circles used for Cookware.

- Q: What should be used in grinding wheel and grinding fluid. Please enlighten master.Because the aluminum rod is soft in the grinding process of grinding cutting aluminum is easy to stick to the surface of the wheel, causing the surface blackening of aluminium rods or rough, we have tried what you said, not the key to solve the problem, I can have the method of experts can provide professional.We are processing the printer core shaft of the company, the product's high precision polishing may not be realized.

- The key method of aluminum rod grinding you. My Baidu space have introduced mill aluminum bar, you can go and see.

- Q: Ask Xi'an where there are aluminum bars, 60-65 of them. If there is a price, probably more money

- Dong Yuan Road No. 70 has sold about 38 yuan / kg in Wei Di apps fear damage

- Q: What fuel does the aluminum rod heater cost most?

- Look at the quality you require. If the quality is not very high, it should be the cheapest gas.

- Q: 1000t extruder, the largest can squeeze 6061 aluminum bars of large diameter

- It depends on the diameter of the extrusion barrel and the cross-section of the extruded profiles. Like you, with about 130 of the cast rod diameter.

- Q: 4.2 of drill bit, drill bit, old broken... Material (aluminum bar).. please help me, how to do it will do well

- The main reason is that the chip removal is not timely! The speed should not be too high, the force should not be too fierce, to drill, retire frequently, not because it is aluminum, that can be hard to drill, and hard to drill, one is to fold the drill bit, and the other is the Kong Zuanpian

- Q: I would like to know the benefits of the aluminum bar homogeneous process and some related knowledge, know the master, please let me know, thank you!

- Homogenizing furnace is an indispensable equipment for improving the quality of aluminum products. After homogenizing the aluminum bars, the internal components (Mg2Si and Fe) are uniform.

- Q: Aluminum bar furnace to the temperature does not cease fire, what's the matter?

- Abnormal judgement and basic maintenance of aluminium rod furnace temperature control instrument:1, to determine whether the normal temperature control instrument, at the time of heating will lower the temperature to the temperature control table, to see whether the burning burning machine, to check whether the normal temperature table, under heating condition, the lower the temperature to the temperature below the temperature, and then look at the burner is not in combustion, if not that there was no abnormal combustion temperature table, otherwise please repair personnel to repair. ?2, regular temperature table surface dust wipe clean, do not let the thermostat with water or other stolen goods. Check thermocouples regularly to see if there is any abnormality.

- Q: What are the diameters of the aluminum bars sold on the market?

- On the market, the general aluminum rod diameter 5, 6, 8, 10, 12, 15, 18, 20mm, 25, 30~95, 100mm (5mm interval), 100~200 (10mm interval), basically extrusion aluminum rod.

- Q: Can the internal and external grinding mill grind the aluminum bar?

- There is no problem with outer grinding, you are not a step, but a cone, and there is no interference

- Q: Can the iron core of an electromagnet be replaced by a steel bar and an aluminum bar?

- The core of DC electromagnet can be used instead of steel bars, but note that this rod must be "iron bar", otherwise the remanence is too big, can't release power.The core of an alternating current electromagnet cannot be replaced by a steel bar because it is heated by a larger eddy.No electromagnet can be used to make an iron core with an aluminum bar.

Send your message to us

One Up Aluminum Bars - AA1100 C.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches