Price of Aluminum Bars - AA1070 D.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1070 D.C Mill Finished Aluminum Circles used for Cookware Description

AA1070 D.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1070 D.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1070 D.C Mill Finished Aluminum Circles used for Cookware

1)Surface Quality : be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

2)Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3)Fine craftsmanship

4)Durable

5)Easy processing

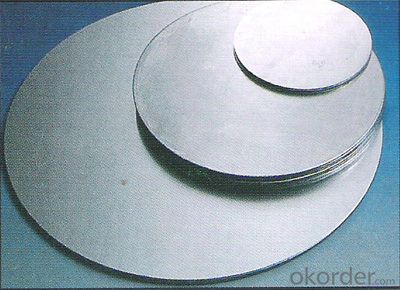

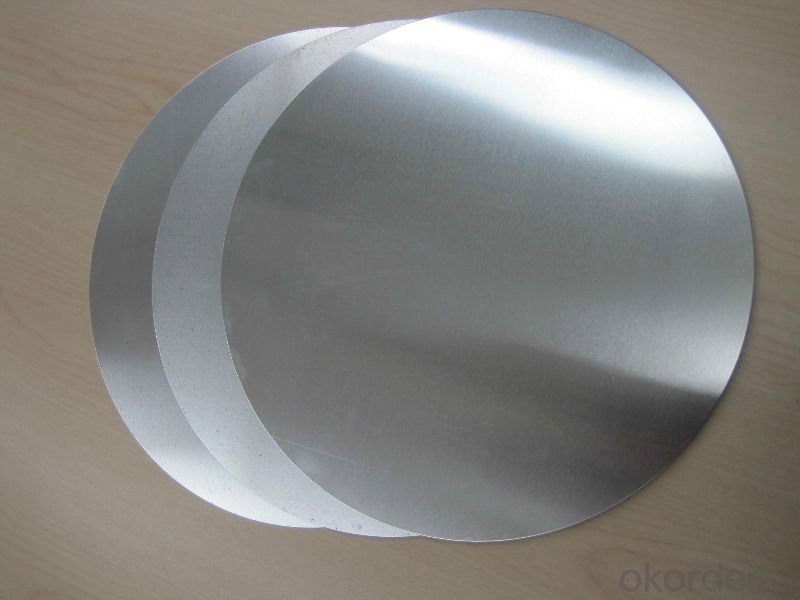

3.AA1070 D.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1070 D.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1070 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1070 D.C Mill Finished Aluminum Circles used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

- Q: How to deal with the burning of 6061 aluminum bars in hard oxidation?

- The burning of aluminum rod is caused by the appearance of excessive appearance when the current density is too large (possibly partial) during anodizing. This is the result of localized or universal catastrophic dissolution of the anodic oxide film, and at the same time, partial or total dissolution of the metal under the film may occur.

- Q: The difference between extrusion and drawing of aluminium bars

- The performance of the extruded bar is worse than that of the drawn bar, and the microstructure and properties of the extruded rod are not uniform.

- Q: How do we pay taxes on the export of raw materials and aluminum rods in the near future? As a matter of fact, we export some aluminum bars and need to pay export duties. I would like to ask: 1. export tariffs how to calculate it? We are trading companies, for example, we purchased 20 yuan / kg, profit: 2 yuan / kg. HS code:7604291099 export tariff rate is: 5%. Freight, customs and so on 1000 yuan. The total quantity is 1000 kilograms. What is the unit price I quoted? How much is the tax (per kilogram)? 2., how to pay export tariffs, is the customs declaration link? The more detailed, the better, thank you. Export duty

- It is common sense to import taxes and export rebates.Export tariffs are returned and no tax is paid. Examples: pesticidesCommodity code 3808911900Other brands of pesticide used in retail packagingTax rate informationMeasurement unit kgPreferential import tax rate of 10%Export tax rate 0%VAT 13%Provisional tax rateGeneral rate of import 35%Export tax rebate rate 5%The export tax rebate rate here is what the country refunded to you, so we must make it clear that only the import will pay taxes!

- Q: How to control the casting speed of casting 90 aluminium bars

- If the water temperature is greater than 40, the water temperature must be reduced in other ways.Looking for national casting orders, purchasing castings, foundry orders, and consulting foundry technology issuesCasting order network

- Q: Our company needs to make the aluminum bar 10 in diameter to be "U", which is done by hand, which is slow. Where is there such a bending device, or is it a fully automatic equipment?

- Ha ha, tell you there is a reward? 10 of the aluminum rod diameter is very small, you can consider using bending machine, or combined punching and shearing machine, punching machine or automatic equipment, how do you want to fully automatic method, to 6 meters of raw materials made directly over U segments, such a down nearly 100 thousand.

- Q: 1000t extruder, the largest can squeeze 6061 aluminum bars of large diameter

- It depends on the diameter of the extrusion barrel and the cross-section of the extruded profiles. Like you, with about 130 of the cast rod diameter.

- Q: Basic information of 6063 aluminum bar

- The role of 1.2 Si and the amount of Si that affect all Mg in the alloy can be in the form of Mg2Si phase, to ensure the full play of the role of Mg. With the increase of Si content, the grain of the alloy becomes thinner, the fluidity of the metal increases, the casting performance becomes better, the strengthening effect of heat treatment increases, the tensile strength of the section increases, while the plasticity decreases, and the corrosion resistance becomes worse.

- Q: Our company is to do aluminum extrusion, first of all, buy aluminum ingot processing into aluminum rods, and then back the company squeezed into aluminum, extrusion process has damaged, damaged from new processing into aluminum rod, how to do accounting entries?

- Outsourcing:Processing materials by entrustmentLoan raw materialPayment of processing fees:Processing materials by entrustmentTax payable - VAT - inputLoan bank depositTake back:Borrow raw materialsEntrusted processing materials

- Q: 6061 aluminum rod representative use

- Five, printing aluminum mainly used for making PS version, aluminum based PS version of the printing industry is a new type of material used in automatic plate making and printing. Aluminum Alloy basic status code: F free state for processing in the molding process, work hardening and heat treatment conditions for the special requirements of the product, the mechanical properties of the products are not specified (not common) O which is suitable for processing products in the annealed state completely annealing was the lowest strength (occasional) H hardening the State applies to improve the strength of the product through the hardening product in hardening after after (or not after) additional heat treatment. The strength decreased (the general non material heat treatment) W solid solution heat treatment state of an unstable state, only suitable for the solid solution after heat treatment. During natural aging at room temperature, the state code said only products in the natural aging stage (not common) T heat treatment (F, O, H in different states) for heat After work, the product is stabilized by (or without) working hardening. T code must be followed by one or more Arabia digital (usually heat treatment reinforced material), our common non heat treatment reinforced aluminum alloy behind the status code is usually the letter H plus two digits. Such as 1100 H14. The following brief describes the meaning of the following status code content. The letter H is followed by two digits: the first number indicates the method of work hardening.

- Q: What are the requirements of aluminium and copper friction welding for aluminum bars?

- There is not much demand, either pure aluminum or aluminum alloy can be welded, of course, the higher the purity, the higher the intensity after welding.Copper and aluminum friction welding machine, we have been doing it for many yearsFriction welding machineShanghai wins spring machinery

Send your message to us

Price of Aluminum Bars - AA1070 D.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches