Aluminum Pipes - AA1060 D.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1060 D.C Mill Finished Aluminum Circles used for Cookware Description

AA1060 D.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1060 D.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1060 D.C Mill Finished Aluminum Circles used for Cookware

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

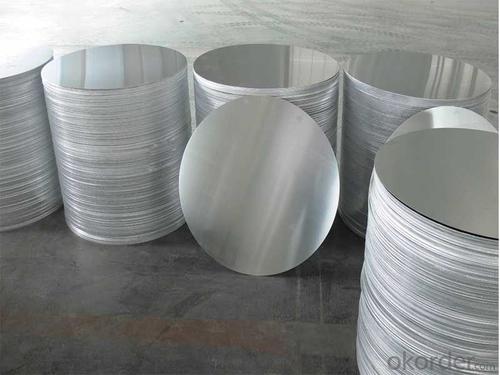

3.AA1060 D.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1060 D.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1060 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

How to guarantee the quality?

---Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1060 D.C Mill Finished Aluminum Circles used for Cookware.

- Q: What are the so-called "aluminum tubes" and "copper aluminum tubes" in air conditioners? Is it the pipe in the outer machine, or the connecting pipe between the outside machine and the inner machine?What materials are used in general external machines? For example, Panasonic, Midea, GREE, Haier, Changhong, CHIGO, Galanz, what are these materials used?

- Hello! Refers to the internal air conditioner and the external machine connecting pipe, the middle of the connecting pipe is an aluminum tube, both ends are made of copper, also known as the aluminum plastic pipe. At present, only GREE and the United States all use pure copper connection tube, other brands only high-end machine only use pure copper connection tube, the ordinary model is the aluminum plastic tube. I hope my answer can help you!

- Q: How can the aluminum pipe burr be convenient?Burr left by drilling

- The internal tube is burr! Not very long words can be a round drill clamp in the round head through a 1 mm wide and about 30 mm in the hole, and then put the paper cut up into 30 broad band card in the slot to rotate in the opposite direction wrapped up! Until Guan Zikong was slightly more than a little good! So you can clear burrs on the inner wall of the!

- Q: The difference between aluminium pipe and galvanized steel pipe

- The aluminum surface has a layer of oxide film, melting point at more than 2000 degrees, and the melting point of aluminum is only about 400 degrees. Galvanized sheet is a sheet of zinc plated on sheet iron or carbon steel.

- Q: External diameter 80mm, diameter 23mm, length 500mm, want to use iron pipe to do external mold, internal mold with iron pipe or solid iron rod processing into taper column (and spray boron nitride release agent), do not know such a practice, OK? In this mode with the taper approach in the aluminum liquid after solidification can easily remove aluminum (because the coefficient of thermal expansion than iron, I am afraid after cooling tubes will (lock core) trouble experienced teacher for advice! Thank you! StopWell, I'll make a small tube of plaster. If the inner mold is not working, will it be stuck together with the aluminum parts? It's not good to clean it

- Where do you put a solid round bar and drill it?.What the middle of the hole diameter of 23 long 500, do much to the taper, also can not play what role of draft.

- Q: What is the chemical composition of aluminum pipes?

- Aluminum pipes are primarily composed of aluminum, which is a chemical element with the symbol Al and atomic number 13. Aluminum is a lightweight and versatile metal known for its corrosion resistance, high thermal conductivity, and excellent strength-to-weight ratio. It is commonly alloyed with other elements to enhance its properties. Some common alloying elements used in aluminum pipes include copper, silicon, magnesium, and zinc. These alloying elements can improve the strength, hardness, and machinability of the aluminum pipe. The specific chemical composition of aluminum pipes can vary depending on the desired properties and application requirements.

- Q: What's the good quality of the aluminum tubes used for air conditioning?

- In fact, in process and technology now, and what is not with aluminum brass difference, only manufacturers reduce the cost, and users are influenced by the traditional view that no aluminum copper good, that their interests are hurt.

- Q: Are aluminum pipes suitable for power plants?

- Yes, aluminum pipes can be suitable for power plants depending on the specific application and requirements. Aluminum pipes offer advantages such as high corrosion resistance, lightweight, and ease of installation. However, their suitability will depend on factors like the type of power plant, operating conditions, and specific needs of the system. It is important to consider factors like temperature, pressure, and compatibility with other materials before determining the suitability of aluminum pipes for power plants.

- Q: An aluminum tube, about 3 meters long, 5 cm in diameter, what is the price?

- Would you like to know how large and thick the aluminum tube you are talking about, and the 6061 material is generally 24 yuan a kilogram

- Q: Aluminium tube production and equipment. What are the production techniques and what equipment are needed? How much will it cost?.

- Familiar with TS16949 quality management system, master of the world's most advanced welding equipment maintenance, equipment procurement and acceptance leading technology used debugging, equipment maintenance and leadership team, prepare equipment maintenance work instruction form, prepare equipment.

- Q: How can the hose of the air conditioner be tightly connected with the aluminum tube?

- A band of stainless steel. Xuyi Europe and America insulation tube Co., ltd.. The main production of automobile air conditioning tube insulation jacket.

Send your message to us

Aluminum Pipes - AA1060 D.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches