Coated Aluminum Pipes Coil-AA3105

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

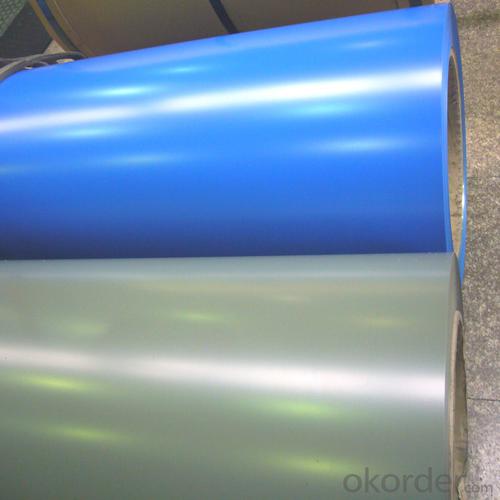

1.General Information of Color Coated Aluminium Coil with Competitive Prices

Aluminum coil is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-4.0mm |

Width: | 10mm- 2000mm |

Coating | PE(Polyester) |

Painting Thickness | Standard 16-25 microns, max 40 microns |

Color | Acording to Ral colors or customer’s samples |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

PE(polyester) Coating

PE(polyester) coating:high molecular polymer as monomer and addition of alkyd, is an UV-resistant coating. It can be classified matt and glossy according to coating gloss. The compact molecule structure, makes paint surface luster and smooth,which assure good printing on the panel surface. With an warranty of 8-10 years for weather resistance, it is specially applied for internal decoration and sign board.

2 Usage/Applications of PE Coated Aluminum Coil/Sheet

Our company's PE Coated Aluminum Coil/Sheet have been widely used in the fields of construction and decoration(garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipe, sanwich panels and drainage, etc.

- Q: What is the specific welding process of T6 aviation aluminium pipe?

- The welding of T6 aerial aluminum pipe is not easy to weld. It is easy to crack. What is the wall thickness? The wall thickness of thin welding also need to fear, in order to ensure the strength of welding after welding, the best immediately after water cooling. It is difficult to distinguish between the ordinary aluminum tube and the eye.

- Q: 502 glue to aluminum and plastic cement do

- The 502 is not the ordinary aluminum and plastic cement, with more than 98% pure sticky metal glue is designed

- Q: Can aluminum pipes be used for brewery equipment?

- Yes, aluminum pipes can be used for brewery equipment. Aluminum is a lightweight, corrosion-resistant material that is suitable for various applications in the brewing industry. However, it is important to consider the specific requirements of the brewery equipment and ensure that the selected aluminum pipes meet those requirements in terms of size, thickness, and compatibility with the brewing process.

- Q: How to weld air conditioning round aluminum tube

- Welding air conditioning thin aluminum tube is mainly a few aspects1, thin aluminum pipe appear grinding leakage, appear big hole2, use for a long time, the needle hole fatigue3, because of corrosion caused by the hole

- Q: Aluminum seamless aluminium oxidation welding line how to do?

- If you decide to buy is seamless aluminium oxide, it is certainly not possible after the welding line, if there is a welding line, that is the hot extrusion of aluminum, aluminum is seamed we usually say, if it is oxidized welding line, there is no way to solve, can't use it can only be scrapped in fact, the hot extruded aluminum tube also can avoid the welding line, this time you have to order and that of the factory, this can be solved above the mold! At least your eye is very ugly after oxidation of a welding line. In fact, seamed pipe and seamless pipe mainly is the surface quality, but the mechanical properties!

- Q: Can aluminum pipes be used for scaffolding?

- Yes, aluminum pipes can be used for scaffolding. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, making it suitable for scaffolding applications. It is resistant to corrosion, easy to handle, and can be assembled quickly, making it a popular choice for scaffolding systems.

- Q: How do you usually process hollow aluminum tubes? I want to make aluminum tubes myself

- An ordinary lathe can be used if continuous casting can be used in large quantities

- Q: Where does the refrigerator copper tube come from? How to distinguish

- Refers to the inside of the condenser tube, in the refrigerator, from the outside can not distinguish,

- Q: Freezer aluminium tube can be used for several years

- This material can be seen, usually screen tube, that is, Bondi tube (iron pipe)It's plate-like or aluminium.Under normal circumstances can use 10 years, this is tested, while others are in the middle may be bad.

- Q: Can aluminum pipes be threaded?

- Aluminum pipes, indeed, have the capability to be threaded. Due to its versatility, aluminum proves to be a material that can undergo machining and threading with ease. To accomplish this, the threading process entails carving helical grooves onto the pipe's exterior surface, enabling connection with other pipes or fittings. For accurate and precise threading, the utilization of suitable tools, such as a threading die, becomes imperative. However, it is crucial to acknowledge that aluminum, being a softer metal in comparison to materials like steel, demands caution to prevent excessive force or damage while threading.

Send your message to us

Coated Aluminum Pipes Coil-AA3105

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches