Aluminum Ac Coil

Aluminum Ac Coil Related Searches

Aluminum Copper Coil Aluminum Alloy Coil Aluminum A Coil Aluminum Wire Coil Aluminum Coil Pipe Copper Aluminum Coil Air Conditioner Aluminum Coil Coil Aluminum Anodized Aluminum Coil Aluminum Tubing Coil Aluminum Siding Coil Aluminum Tube Coil China Aluminum Coil Aluminum Condenser Coil Aluminum Roof Coil Aluminum Evaporator Coil Pvc Aluminum Coil Buy Aluminum Coil Aluminum Fin Coil Aluminum Fascia Coil Aluminum Coil Pe All Aluminum Coil Coil Of Aluminum Aluminum Strapping Coil Aluminum Coil Price Coil Coating Aluminum Aluminum Gutter Coil Roll Aluminum Coil Aluminum Coil White Aluminum Coil WholesaleAluminum Ac Coil Supplier & Manufacturer from China

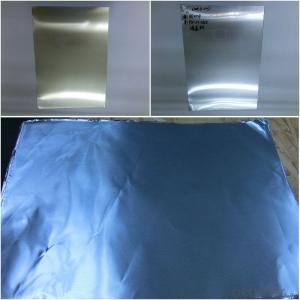

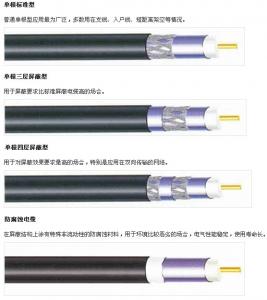

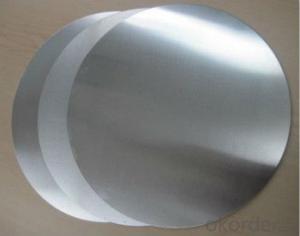

Aluminum AC Coil is a versatile product that consists of aluminum sheets or coils specifically designed for various applications in the construction, automotive, and manufacturing industries. These coils are known for their excellent strength, durability, and corrosion resistance, making them a popular choice for a wide range of uses. The product is available in different thicknesses, widths, and finishes, allowing customers to select the most suitable option for their specific requirements.The aluminum AC coil finds its application in numerous scenarios, such as in the production of air conditioning units, heat exchangers, and various other cooling systems. Its lightweight nature and high thermal conductivity make it an ideal material for these applications, ensuring efficient heat transfer and optimal performance. Additionally, the coils can be easily fabricated and shaped into various forms, making them suitable for a multitude of projects and designs.

Okorder.com is a reputable wholesale supplier of aluminum AC coil, boasting a vast inventory that caters to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that the aluminum AC coil they provide meets the highest industry standards. Their extensive range of products allows customers to find the perfect aluminum AC coil for their specific needs, making them a reliable choice for businesses and individuals alike.

Hot Products