Aluminum Coil for Any Use

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

Aluminium foil has a shiny side and a matte side. The shiny side is produced when the aluminium is rolled during the final pass. It is difficult to produce rollers with a gap fine enough to cope with the foil gauge, therefore, for the final pass, two sheets are rolled at the same time, doubling the thickness of the gauge at entry to the rollers. When the sheets are later separated, the inside surface is dull, and the outside surface is shiny. This difference in the finish has led to the perception that favouring a side has an effect when cooking. While many believe that the different properties keep heat out when wrapped with the shiny finish facing out, and keep heat in with the shiny finish facing inwards, the actual difference is imperceptible without instrumentation.The reflectivity of bright aluminium foil is 88% while dull embossed foil is about 80%.

We provide a full range of precision aluminum strip for almost any application. We produce aluminum strip in a wide variety of alloys, including clad composites. Our aluminum strip can be produced in standard dimensions or custom made to your special requirements. We produce both imperial and metric units. We manufacture in compliance with the main international specifications, and tighter tolerances or custom tempers are available upon request. We offer various surface conditions, custom finishes (painting, anodizing, embossing), special processing, and multiple packaging options to meet our customer's unique requirements. The following is a summary of our capabilities.

Manufactured in compliance with the main international specifications and standards, including: Aluminum Association, ASTM, EN, and DIN.

We can also manufacture in compliance with other international standards including:ASME, SAE, AMS, AWS, FED, MIL, QQ, ISO, BS, AFNOR, JIS and GOST.

Manufactured in compliance with the main international specifications and standards.

Tighter tolerances are available upon request.

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface. Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals. Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest.

Coal (from the Old English term col, which has meant "mineral of fossilized carbon" since the 13th century)is a combustible black or brownish-black sedimentary rock usually occurring in rock strata in layers or veins called coal beds or coal seams. The harder forms, such as anthracite coal, can be regarded as metamorphic rock because of later exposure to elevated temperature and pressure. Coal is composed primarily of carbon along with variable quantities of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Throughout history, coal has been used as an energy resource, primarily burned for the production of electricity and/or heat, and is also used for industrial purposes, such as refining metals. A fossil fuel, coal forms when dead plant matter is converted into peat, which in turn is converted into lignite, then sub-bituminous coal, after that bituminous coal, and lastly anthracite. This involves biological and geological processes that take place over a long period. The Energy Information Administration estimates coal reserves at 948×109 short tons (860 Gt).One estimate for resources is 18 000 Gt.

Coal is the largest source of energy for the generation of electricity worldwide, as well as one of the largest worldwide anthropogenic sources of carbon dioxide releases. In 1999, world gross carbon dioxide emissions from coal usage were 8,666 million tonnes of carbon dioxide.In 2011, world gross emissions from coal usage were 14,416 million tonnes.Coal-fired electric power generation emits around 2,000 pounds of carbon dioxide for every megawatt-hour generated, which is almost double the approximately 1100 pounds of carbon dioxide released by a natural gas-fired electric plant per megawatt-hour generated. Because of this higher carbon efficiency of natural gas generation, as the market in the United States has changed to reduce coal and increase natural gas generation, carbon dioxide emissions have fallen. Those measured in the first quarter of 2012 were the lowest of any recorded for the first quarter of any year since 1992.In 2013, the head of the UN climate agency advised that most of the world's coal reserves should be left in the ground to avoid catastrophic global warming.

Coal is extracted from the ground by coal mining, either underground by shaft mining, or at ground level by open pit mining extraction. Since 1983 the world top coal producer has been China.In 2011 China produced 3,520 million tonnes of coal – 49.5% of 7,695 million tonnes world coal production. In 2011 other large producers were United States (993 million tonnes), India (589), European Union (576) and Australia (416).[9] In 2010 the largest exporters were Australia with 328 million tonnes (27.1% of world coal export) and Indonesia with 316 million tonnes (26.1%),while the largest importers were Japan with 207 million tonnes (17.5% of world coal import), China with 195 million tonnes (16.6%) and South Korea with 126 million tonnes (10.7%).

- Q: Good rubber, shifters on downtube, good gel seat and handlebar tapeThis bike was ridden by a bike shop owner in Wisconsin and was rarely used by meIn very, good condition.

- This bike was actually a 1990 modelIt never left me stranded and was always up for the taskThe only things that I did to it during my time with my 1400 is upgrade from down tube to STI shifters and switched to 9 speed with Performance Forte Titan wheels (read my comments on those wheels that section) Kudos to Trek for making such a well-made frameNewer aluminum models may be lighter, but the attention to detail is better on this oneIt was one of the best bikes that I've ever ownedUnfortunately it was totaled when my wife drove into our garage with my bike on the roof of my Honda CR-VThere was a crack in the frame that was unrepairable and was not under warrantyTrek went out of their way in trying to rectify this problem buit the bike was too old and it was before the started the lifetime warranty on their bikesThe rep for Trek still went out of his way to help me over a five week span, calling me every other day to update me on the status of my claimI was so impressed that I bought a 5200 Trek after thatIf you find a Trek 1400 or 1500 (Trek still makes the 1500), you won't regret itI gave it a 4 out of 5 because they don't make the 1400 anymore.

- Q: i know what aluminum is but oxide is not found on the periodic table, and the teacher also gave us a list of common oxidation numbers for polyatomic ions and it is not there also, can anyone help me?

- Aluminum Oxide = Al2O3 Oxidation number of Al = +3 Oxidation number of O = -2 1 mol of Al weights 26.98 g | 1 mol of O weights 16 g You have to atoms of Al, so: 26.98 *2 = 53.96 g/mol You have 3 atoms of O = 16 *3 = 48 g/mol 53.96 + 48 = 101.96 g/mol == Molar mass of Al2O3 That means that in 1 mol of Al2O3 weights 101.96 g

- Q: 6063, aluminum pipe welding with what kind of welding rod?

- If there is an air hole, it will be repaired again, which will affect the efficiency of the finished product, and also need polishing treatment.This kind of pipe joint welding welding welding temperature you can use, your ultimate goal of the pipe joint is to ensure the final pressure, and molding soldering really save itself because the argon arc welding process of welding the meat which need to be addressed, and the joint strength itself don't require relatively low, so low welding is the mainstream, if you can get in touch with Wei Odin welding company, 022-28196887 further communication.

- Q: Are aluminum sheets suitable for interior design applications?

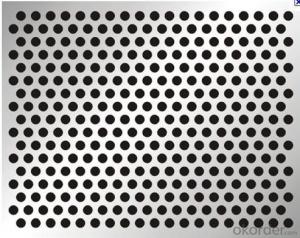

- Aluminum sheets are an excellent choice for interior design purposes. This material is both versatile and durable, allowing for various creative uses in enhancing the aesthetics of indoor spaces. Its malleability enables easy shaping, cutting, and manipulation, resulting in unique and contemporary designs. Different finishes, such as brushed, polished, or textured, further expand the design options. One major advantage of utilizing aluminum sheets in interior design is their lightweight composition. This feature simplifies handling and installation, reducing labor and transportation expenses. Additionally, aluminum's corrosion resistance makes it perfect for environments with high humidity or moisture, such as bathrooms or kitchens. Aluminum sheets find application in various aspects of interior design, including wall cladding, ceiling panels, room dividers, furniture, and decorative elements. The ability to paint or coat them in different colors allows seamless integration into any design scheme. Furthermore, perforation or engraving can create patterns or intricate designs, adding a distinct visual appeal to the space. Moreover, aluminum is a sustainable material with high recyclability. The recycling process consumes significantly less energy compared to the production of new aluminum, making it an environmentally friendly option for interior design applications. To summarize, the versatility, durability, lightweight nature, corrosion resistance, and manipulability of aluminum sheets make them highly suitable for interior design. They offer numerous design possibilities and can be used in various applications, rendering them a popular choice among designers and architects.

- Q: In extruded aluminum shapes, there are often voids that are created, in order to form structural ribsOther than secondary welding operations, by what process are these voids created in lengthy extruded structural shapes?

- Recycling pays for itself, the earnings made out of recyling waste is sufficient to pay for sequence and the recycling techniqueMy different placed up pertains to this, i herd on radio 4 of a ecu usa recycling and utilising the recycling salary to pay for the completed techniquethe united kingdom is probably going one in all the worst in europe for recycling as exchange into pronounced on the information this weekend, in spite of the certainty we are between the wealthiest countriesIf the ambience isn't an significant factor in determining who you vote for, the politicans and government wont do everywhere close to sufficient, as a substitute focusing on what you will vote them in forLike greater own wealth.

- Q: What are the different assembly options available for aluminum profiles?

- There are several assembly options available for aluminum profiles, including mechanical fastening methods such as screws, bolts, and rivets. Additionally, adhesive bonding and welding techniques can also be used to join aluminum profiles together. The choice of assembly method depends on factors such as the desired strength, aesthetics, and ease of disassembly if required.

- Q: Are you concerned about consuming or absorbing the neurotoxin aluminum? What measures do you take to avoid them?Sources:saltbaking powderAs well as in some: tooth fillingsdeodorantantacidsSome studies indicate that patients with Alzheimer's have traces of aluminum in their brains.

- The increased aluminum doesn't seem to be a consistent finding, and if there is a real association, it's only hypothetical that it might be causal, and if the association is causal, it's also only a hypothesis that decreasing absorption would make a difference. That's a long, long way from recommending any change in your life. Associations crop up in medicine on a routine basis and rarely turn out to be meaningful.

- Q: Is it safe to use aluminum coil for food storage?

- <p>Using aluminum coil for storing food is not recommended. Aluminum can react with acidic or alkaline foods, potentially leaching aluminum into the food. This can be harmful to health, especially over time. Instead, opt for food-safe materials like glass, stainless steel, or BPA-free plastics for food storage to ensure safety and prevent contamination.</p>

- Q: I just heard about it in passing and think it might be fun to tryHmmm? brownies with the fiber of beansgood ideaI am always trying to sneak a little extra nutrition into my cooking without my kids and grandkids knowing itLOL

- a couple of things: 1Tanishia - how does one become a great matchmaker/love columnist if they have such a great social anxiety that they don't leave the house? call it common sense, call it a degree in psychology, but generally speaking if a person has no ability to be social, how do they get a job? that would require talking to someone at some pointa better flaw would be like Raj from TBBT who can't talk with a girl presentthat being said there are ways to fix it, like making her afraid of falling in loveor making her a blogger in her parent's basement who lies and makes an ideal self profile, which someone takes and interest inlike catfish2back to the questionas i agree with most answers on here - come up with your own ideas instead of asking for themthat is called originalitythat being said, i'm gonna give you some free advicearead a book about storytellingbin case you are lazy and decide not to actually study how to write a story, here are the componentsstep onemake up a protagoniststep twogive the protagonist a personalitystep threegive the protagonist a flawor a fewstep fourgive the protagonist a goalstep fivemake up an antagonist to prevent that goaloptional step sixcreate a love interest or buddy for your protagonistthey can also be the antagonistcongratulations, you have the basics of a storynow writeand don't plagiarize.

Send your message to us

Aluminum Coil for Any Use

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords