Aluminum Roofing Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

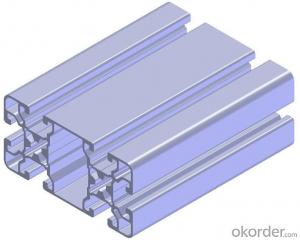

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

- Q: I have everything I need to make fruit leather except nonstick liner and was wondering aluminum foil would workI also have parchment paper

- Yea.Foil will workI use it when I run out of parchment or wax paperIt will peel right off! ;)

- Q: Do you get AWS certified on a specific type of welding machine and material? Or does it only differ on certification class? At work they want me to pass a 6G certification and it's using the mig welder with a 1/2 aluminum pipeI don't have much experience with the mig welderI do however have years of experience with the TIGObviously the TIG isnt strong enough for 1/2 inch alluminumI was wondering if I could take the 6g test with a thinner material and using the TIG welderWould it be equivalent???Thanks for your help in advance.

- It goes back in time infinitely! Lice can't create themselves - they just crawl from one warm head to the next at every opportunity.

- Q: I just bought brachs carmel candiesdo you melt them on a stoveDo you add evaporated milk? HELP HELP HELP!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- 6 Granny Smith apples 6 wooden sticks 1 (14 ounce) package individually wrapped caramels, unwrapped 2 tablespoons water 1/2 teaspoon vanilla extract Insert wooden sticks 3/4 of the way into the stem end of each applePlace apples on a cookie sheet covered with lightly greased aluminum foilCombine caramels and water in a saucepan over low heatCook, stirring often, until caramel melts and is smoothDip each apple into the caramel and gently run apples around insides of saucepan to scrape off some of the caramelScrape excess caramel from the apple bottoms using the side of the saucepanPlace on the aluminum foil and chill until ready to serve.

- Q: What types of aluminum sheets are recommended for outdoor applications?

- <p>Yes, there are specific types of aluminum sheets suitable for exterior use. These include aluminum sheets with a protective coating, such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a Kynar 500庐 PVDF coating are highly resistant to UV rays, making them ideal for exterior applications. Marine-grade aluminum is also recommended for exterior use due to its superior corrosion resistance, especially in coastal areas. These types of aluminum sheets are designed to withstand harsh outdoor conditions and maintain their integrity over time.</p>

- Q: standard kitchen aluminum foil has two sides per sheet one is shiney the other is dull bake on?

- Actually, both sides are the sameThe only difference is that when the aluminum is rolled up, the part that touches the rolling mechanism becomes shinyIt doesn't make a difference what side you use, as aluminum will cook well on either sideIf however, you want it to reflect well, you should use the shiny side towards what you want it to reflect.

- Q: why does my chicken taste like metal when i put aluminum foil in the bottom of the pan?

- Maybe the chicken absorbs mild rust from the foil

- Q: What is the typical thermal expansion coefficient for aluminum coils?

- The typical thermal expansion coefficient for aluminum coils is around 23.1 x 10^-6 per degree Celsius (or 23.1 x 10^-6/°C). This coefficient represents the change in length of an aluminum coil per degree Celsius increase in temperature. It is important to note that this value may vary slightly depending on the specific alloy and composition of the aluminum coil.

- Q: Had this problem: every time i use a removable bottom pan, it drips in my oven, smoke comes out, and i either have to stop baking or deal with the smoke alarm!??!?! I can't understand! And if i keep baking, then i have to spend a lot of time cleaning the oven, from the burnt sugar that had formed on the bottom.Any ideas?

- The only suggestion I would give, is to wrap heavy duty aluminum foil around the outside of the pan before placing your ingredients into the panCover the bottom with foil and bring it up around the edges, then crimp it around the top edge of your panI do this every time that I make cheesecake, because I place the cheesecake in a water bath in the oven and don't want the water seeping into my springform panAlthough I do it for a different reason, it would definitely prevent any leaks, and would keep you from having to clean up a mess afterwardsGood luck! :)

- Q: I have some store bought paste but that is entirely too much workSurely there is a better way and if you know what it is please share your secret with me.

- Step1 Place a piece of aluminum foil (shiny side up) in a glass dish, such as a 9x13 glass baking dishStep2 Place your silver jewelry pieces on top of the aluminum foil and cover the jewelry with boiling waterBe careful that you don't splash the hot water on yourselfStep3 Add 2 Tablespoons of Baking Soda and 1 teaspoon of Salt to the hot waterSoak silver jewelry pieces for 30 minutesYou will, almost immediately, see how the chemical reaction of the foil, baking soda and salt magically make the tarnish disappearStep4Using salad tongs, remove the silver jewelry from the hot waterYou can also just drain the jewelry into a colanderRinse the jewelry with sudsy water, dry and buff with a soft clothVoila!! Your silver looks beautiful!

- Q: okay so I have a limit to what I can use, the materials listed below, no more, no lessMy teacher said that the secret is the staws but I'm not exactly sure what he means? Rules of the Challenge: The egg and your safety device will be dropped from a height of 5 meters.Your safety device should not contain a parachuteAll of the materials you use to make the safety device must fit into the brown lunch bag.Your safety device does not need to survive the impact-only the eggYou do not need to use all of the materials (although you may use the materials in any way that you will including tearing/breaking)Materials Provided : 1 brown paper lunch bag3 Ziploc plastic bags (sandwich size)1 piece of newspaper2 pieces of paper towel1 meter of masking tape1 30cm piece of string5 cotton balls1 styrofoam cup1 sheet of aluminum foil (30 cm)Please HelpI already tried out my ideas and they didn't work!

- my best advice is to think of 'crush zones' similar to that of a modern caranother idea is to make sure that the impact happens all in one spotwhat i would do is take the cup.crumple up the zip lock bags and put them in the bottom of the cup, then put on top of that the paper towel, then on top of that the cotton balls and then make a spot for the egg to go on top of those itemsmake sure that the cup is bottom heavy and put some trailers on top of them cup to make sure the bottom of the cup hits the groundgood luck!

Send your message to us

Aluminum Roofing Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords