Aluminum Foil Facing Insulation for Roofing and Walls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Aluminum Foil Facing

Aluminum Foil Facing is a kind of film, which is made of by the aluminum foil, fiberglass scrim and Kraft paper. Someone is made of by aluminum and PE woven fabric cloth.

Application of Aluminum Foil Facing

Our aluminum foil facing are mainly used as facing for glass wool insulation, rockwool ,mineral wool etc. Also aluminum foil facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter.

Advantage of Aluminum Foil Facing

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Aluminum Foil Facing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

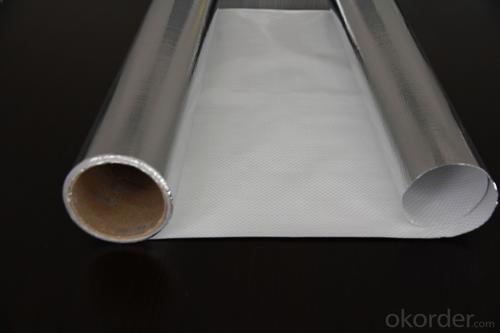

Pictures of Aluminum Foil Facing

Specification of Aluminum Foil Facing

CONSTRUCTION:

Aluminum foil: 7 microns

Tri-way fiberglass scrim: M.D: 8/100mm; X.D: 12/100mm

Adhesive: Polyethylene

Kraft paper: 50gsm (Natural)

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 88 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 110 50 | ASTM D828 |

Burst strength | N | 30 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of Aluminum Foil Facing and is one of the large-scale professional investment Aluminum Foil Facing bases in China. Annually more than 1000 containers of Aluminum Foil Facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: The user is asking if they can reuse their old aluminum foil facing to create new ones once it becomes worn out.

- <p>No, you cannot create new aluminum foil facings from old, worn-out ones. Aluminum foil facings are typically made from a specific type of aluminum that is bonded to a substrate. Once it wears out, the aluminum layer is compromised and cannot be reused to make new facings. Recycling old aluminum foil is the best option to reduce waste and conserve resources. You can recycle aluminum foil, which will then be processed and turned into new aluminum products.</p>

- Q: Is it safe to use aluminum foil as a wrapping material for food to be fried?

- <p>Yes, you can use aluminum foil to wrap food and fry it. Aluminum foil is heat resistant and can withstand high temperatures, making it suitable for frying. However, it's important to ensure that the foil is securely wrapped around the food to prevent any oil from seeping in and to avoid any foil from breaking off into the oil, which could be a fire hazard. Always follow safety guidelines when deep frying with aluminum foil to prevent accidents.</p>

- Q: This question asks for the correct method of storing aluminum foil to keep it from getting tangled or damaged.

- <p>To store aluminum foil facing properly, first ensure that the foil is clean and dry. Roll it tightly starting from the shiny side, which should be facing outward. Secure the roll with a rubber band or a piece of tape. Store the roll in a cool, dry place, away from direct sunlight to prevent damage and to maintain freshness. Some people also use a paper towel tube to help keep the foil roll compact and prevent it from unraveling.</p>

- Q: What are the safe and effective alternatives to aluminum foil for food packaging?

- <p>Yes, there are several substitutes for aluminum foil facing that are safe and effective for food packaging. One such alternative is parchment paper, which is non-toxic and can withstand high temperatures without releasing harmful chemicals. Silicone baking mats are also a good option, as they are reusable, non-stick, and can be used in both the oven and freezer. Additionally, beeswax wraps can be used as a natural, eco-friendly alternative for wrapping food, although they may not be suitable for high-temperature cooking. It's important to ensure that any substitute used is food-safe and can handle the intended cooking temperature to maintain food safety and quality.</p>

- Q: Is it safe to use aluminum foil with a reflective side for storing food?

- <p>Yes, aluminum foil facing can be used for food storage. It is commonly used to wrap, cover, or store food in the refrigerator or freezer. The reflective side of aluminum foil is safe for food contact as it is made of a food-grade material. However, it's important to ensure the foil is clean and free from any damage or sharp edges that could puncture other food packaging. It's also advisable to avoid using it in direct contact with acidic or alkaline foods, as this can cause the foil to corrode and potentially release aluminum into the food.</p>

- Q: What are some alternative uses for old aluminum foil that are not commonly known?

- <p>Yes, there are several creative uses for old aluminum foil. You can use it to clean stubborn grime from pots and pans, as it can effectively scrape off burnt-on food without scratching surfaces. Aluminum foil can also be used to sharpen scissors by cutting through it multiple times. It can be fashioned into a fire starter for camping, as it retains sparks and heat well. Additionally, it can be used to create a makeshift funnel for pouring liquids or to wrap around stems of plants to protect them from frost. These are just a few of the many potential uses for old aluminum foil.</p>

- Q: This question asks for the method to wrap a hot pan using aluminum foil, with specific instructions on how the foil should face.

- <p>To wrap a hot pan with aluminum foil, first ensure the pan is stable and on a heat-resistant surface. Take a large piece of aluminum foil, about twice the size of the pan. Hold one corner of the foil and drape it over the pan, allowing the shiny side to face the pan. Gently press the foil against the pan, working your way around the edges to cover the entire surface. Ensure the foil is snug but not too tight to avoid tearing. The shiny side facing the pan will help reflect heat and protect the pan's surface. Be cautious while handling the hot pan and aluminum foil to avoid burns.</p>

- Q: Explain the distinctions among various types of aluminum foil facing materials.

- <p>Aluminum foil facing can be categorized into several types based on their composition and application. Type 1 is plain aluminum foil, commonly used for food packaging and general wrapping. Type 2 is aluminum foil laminated with plastic, which offers better barrier properties and is used in flexible packaging. Type 3 is aluminum foil laminated with Kraft paper, providing a sturdier material for packaging and insulation. Type 4 is aluminum foil laminated with polyethylene, which is waterproof and used for construction and insulation. Each type has unique properties, such as barrier resistance, strength, and heat resistance, making them suitable for different applications.</p>

- Q: Explain the distinct characteristics of aluminum foil facing compared to other metal facings.

- <p>Aluminum foil facing is a type of metal facing material that is made from thin sheets of aluminum, known for its light weight, high reflectivity, and excellent heat resistance. It is commonly used in construction for insulation and moisture protection. In contrast, other types of metal facings, such as steel or copper, may offer different properties. Steel facings are often stronger and more durable but can be heavier and less resistant to corrosion without protective coatings. Copper facings are known for their natural resistance to corrosion and can be used in applications requiring antimicrobial properties or high thermal and electrical conductivity. Each type of metal facing has its unique advantages and is chosen based on specific application needs.</p>

- Q: This question asks for the optimal methods of storing food in containers not made of traditional food-safe materials.

- <p>The best ways to store food in containers made from alternative materials involve ensuring the containers are food-safe and do not impart any harmful substances to the food. For glass containers, ensure they are free of lead and are properly sealed to maintain freshness. For stainless steel containers, avoid those with non-food-grade coatings and ensure they are well-sealed to prevent spoilage. For silicone or plastic containers, look for BPA-free options and avoid high temperatures that could cause the material to leach chemicals. Always check for any odors or tastes that the container might impart to the food, and never store acidic foods in non-acid-resistant containers as this can lead to chemical reactions and contamination.</p>

Send your message to us

Aluminum Foil Facing Insulation for Roofing and Walls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords