Aluminum Awning Windows

Aluminum Awning Windows Related Searches

Aluminum Awnings Aluminum Gates Steel Window Awnings Aluminum Wall Panels Insulating Aluminum Window Frames Exterior Metal Window Awnings Aluminum Exterior Wall Panels Mechanical Awnings Aluminum Wheels Aluminum Fence Panels Aluminum Wall Plate Aluminum Plate Wall Panels Folding Aluminum Chairs Aluminum Foil Wrap Aluminum Electrical Wiring Aluminum Winch Plate Aluminum Frame Tents Aluminum Foil Leaves Aluminum Wrapping Foil Aluminum Foil Insoles Aluminum Foil Blankets Aluminum Cover Plate Aluminum Plate Panels Aluminum Wall Panels Exterior Aluminum Foil Hats Aluminum Tape Aluminum Foil Wrap Sheets Roof Aluminum Foil Shop Front Awnings Aluminum Sealing TapeAluminum Awning Windows Supplier & Manufacturer from China

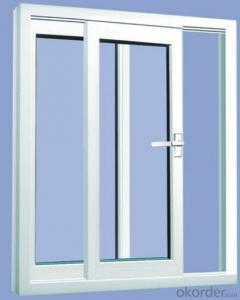

Aluminum Awning Windows are a type of window that features a unique design, characterized by their ability to open outwards and provide excellent ventilation and protection against rain. These windows are made from high-quality aluminum, ensuring durability and resistance to various weather conditions. They are an ideal choice for both residential and commercial properties, offering a combination of functionality and aesthetic appeal.Aluminum Awning Windows are widely used in various settings, such as homes, offices, and public buildings, where they provide a practical solution for natural light and air circulation. They are particularly popular in regions with frequent rainfall, as their design effectively prevents water from entering the interior space. Additionally, these windows can be easily integrated into modern architectural designs, enhancing the overall appearance of a building while maintaining their practical benefits.

Okorder.com is a leading wholesale supplier of Aluminum Awning Windows, boasting a vast inventory of this product to cater to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Aluminum Awning Window is manufactured to the highest standards, providing a reliable and long-lasting solution for any building project.

Hot Products