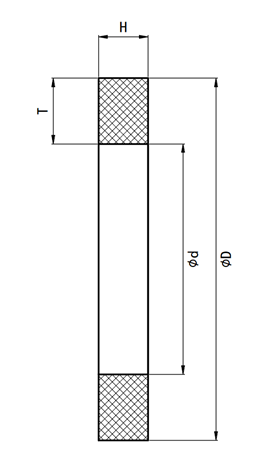

Polytetrafluoroethylene add glass fibre add oxide PTFE gaskets liner Shim Spacer Pads customized

- Loading Port:

- SHENZHEN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Material:

ptfe add glass fibre add oxide

If you need a large quantity of products, different materials or sizes, please contact customer service.

High quality factory, focus on high-end seals! Fast shipping!

A gasket is a material or combination of materials clamped between two separate joints (flanges) and serves to maintain a seal between the two joints for a predetermined service life. The gasket must be able to seal the joint surfaces and ensure that the sealing medium is impermeable and non-corrosive, and can withstand temperature and pressure, etc.

- Q: What are the causes of cracks in vulcanized rubber products?

- When vulcanized rubber products are cracked, it shows that high sulfidation temperature, poor material flow, short scorch time, and partial scorch of rubber compound cause cracks.

- Q: Rubber Mooney value is what meaning, what is the role of

- In accordance with the provisions of the standard GB 1232 (Mooney viscosity), rotation expressed by the symbol Z100 C 1+4. Where Z rotational viscosity; 1, preheating time is 1min; 4 - rotation time is 4min; 100 C - test temperature of 100 degrees.In our country, usually with ML100 or MS100 1+4 to 1+4 DEG C said. M said L Mooney, represented by the greater trochanter, S said with a small rotor.1 preheat for 1 minutes, 4 said that the test for 4 minutes. The larger the value of Mooney viscosity, said, the plastic is widely used as a low. Index control process performance of rubber.

- Q: What advantage does ethylene propylene rubber with three yuan compare to two yuan ethylene propylene rubber?

- In recent years, the third monomer and new technology development, foreign developed 1 7- octadienoic, 6, 5, two 10- methyl -1, 9- eleven, 7- two three ene 3, methyl -1, 6- octadienoic, 5 7-, two methyl -1, 6- octadienoic, 7- methyl -1, 6- octadiene as the three EPDM third monomer, the performance of three Yuan rubber has been enhanced. The monomer and content of third monomer in three yuan ethylene propylene rubber have direct influence on vulcanization rate and vulcanizate property. Among them, dicyclopentadiene (DCPD) as the third monomer, although the price is low, but the three Yuan rubber vulcanization speed is slow, difficult and high degree of unsaturation diene rubber and use; to ethyiidenenorbomene (ENB), 6 10-, two methyl -1, 5, third monomer three Yuan rubber vulcanization speed 9- eleven three ene as fast, the former has become the main varieties of three yuan of ethylene propylene rubber. The third monomer content in iodine said three EPDM iodine value is generally 6-30, mostly around 15. The iodine value is 6-10, curing speed is slow, difficult and high unsaturated rubber; iodine value is 25-30, for ultra high speed curing type, available in any proportion and high unsaturated diene rubber and use. Therefore, three yuan ethylene propylene rubber and other rubber in use, should pay attention to choose the appropriate three yuan ethylene propylene rubber varieties.

- Q: How can the frictional properties of rubber improve?

- The viscoelastic parameter tan delta has a direct influence on the friction force, while the decrease of the rubber cross degree makes the tan delta increase. Therefore, the friction coefficient increases, and the friction coefficient and wear increase as well. From a physical and chemical point of view, the weaker the cross-linking, the higher the rate of wear is due to a lower degree of cross-linking which is easily caused by mechanical stress. It is found that the crosslinking degree of ethylene propylene three - element rubber increases with the irradiation of electron beam, which reduces the friction.

- Q: Aging of rubber parts for automobiles

- Due to the comprehensive effect of various internal and external factors, rubber products will deteriorate the chemical properties and mechanical properties of this kind of phenomenon is realized by rubber aging, cracking, sticking, hardening, powder, mold. Shute rubber reminder, especially the rubber parts on the vehicle, due to the complex use of the environment, aging accelerated more obvious.

- Q: What are the rubber parts for the car?

- Filter rubber parts, cloth (diaphragm), injection pump sealing ring, car frame sealing strip, door seal..... There are many, the car inside the big, small, a lot of rubber products. Watch more and you'll see.

- Q: What is the size of the scorch time of the rubber?

- Rubber is a mixture of organic and inorganic compounds. The main component is organic matter, and the scorch time can reflect the weather resistance and fire resistance of the product.

- Q: Half finished rubber film surface white is going on

- Rubber is a latex made from rubber, tree, rubber, and grass. It is made of flexible, insulating, impermeable and air. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: How to identify the tire rubber is raw or cooked

- Rubber is a kind of polymer material with high elasticity, is the parent material manufacturing of rubber products, generally refers to the rubber unvulcanized. A nearly neutral liquid produced by a rubber tree and added with 0.05%~0.1% ammonia water to make latex (for a short period of time). Most of the latex need processed dry glue, all kinds of natural rubber is often said.

- Q: What kind of rubber does TPE belong to?

- Thermoplastic elastomer TPE (Thermoplastic, Elastomer) is a kind of material with high elasticity, high strength, high resilience, and has the characteristics of injection molding. Nontoxic security, wide range of hardness, with excellent color, soft touch, weather resistance, fatigue resistance and temperature resistance, excellent processing performance, without curing, can reduce the cost of recycling, can be two times of injection molding, and PP, PE, PC, PS, ABS and other base materials the adhesive, can also be a separate molding.

Send your message to us

Polytetrafluoroethylene add glass fibre add oxide PTFE gaskets liner Shim Spacer Pads customized

- Loading Port:

- SHENZHEN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords