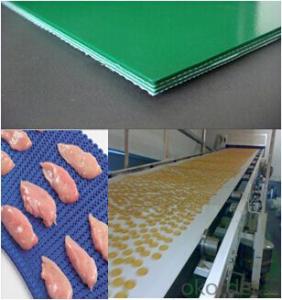

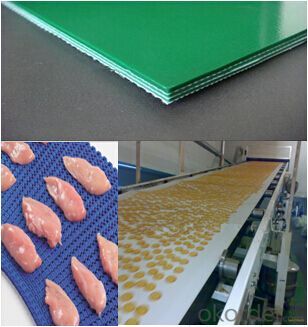

ISO Standard PVC Flat Conveyor Belt PVC Green Belt Conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ISO Standard PVC Flat Conveyor Belt PVC Green Belt Conveyor

Specifications

Anti-static and tearing resistant

Abrasion and oil/heat/fire resistant

Working temperature ranges from -10 to 80Deg.C

With advanced coating machine and other excellent facilities, we are professionally producing PVC&PU light conveyor belts, which are extremely suitable for light industry such as beer industry, paper making industry, food industry, textile industry etc.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

* Working temperature ranges from -10 to 80Deg.C

| code | Top cover | Bottom Cover | Thick | Characteristics | Fabrics | ||||

| Material | Colour | Surface | Material | Colour | Surface | mm | Plies | ||

| PVC conveyor belt | |||||||||

1/10 S/P W | PVC | White | Smooth | - | Natural | Fabric | 1.0 | Antistatic | 1 |

1/12 S/S BK | PVC | Black | Smooth | PVC | Black | Smooth | 1.2 | 1 | |

1/16 D/STF BK TM | PVC | Black | Diamond | - | Natural | Strong Fabric | 1.6 | Tread mill | 1 |

2/12 P/P W | Fabric | Natural | Fabric | Fabric | Natural | Fabric | 1.2 | Antistatic | 2 |

2/18 P/P W | Fabric | White | Fabric | - | Natural | Fabric | 1.8 | Antistatic | 2 |

2/20 D/P AG | PVC | Apple Green | Diamond | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/2O S/P AG | PVC | Apple Green | Smooth | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/20 S/P PG | PVC | Petrol Green | Smooth | - | Natural | Fabric | 2.0 | No-antistic | 2 |

2/20 M/P BK | PVC | Black | Matt | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/20 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 2.0 | FDA | 2 |

2/20 S/P W | PVC | White | Smooth | - | Natural | Fabric | 2.0 | 2 | |

2/20 S/P BK | PVC | Black | Smooth | - | Natural | Fabric | 2.0 | 2 | |

2/25 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 2.5 | FDA | 2 |

2/30 S/FF PG | PVC | Petrol Green | Smooth | - | Natural | Flexible Fabric | 3.0 | Cold-Resistant | 2 |

2/30 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 3.0 | FDA | 2 |

2/30 S/P AG | PVC | Apple Green | Smooth | - | Natural | Fabric | 3.0 | Antistatic | 2 |

2/30 LR/SF AG | PVC | Apple Green | Longitudinal Lib | - | Natural | Silent Fabric | 3.0 | 2 | |

2/30 S/D W FDA | PVC | White | Smooth | PVC | White | Diamond | 3.0 | FDA | 2 |

2/30 S/D W | PVC | White | Smooth | PVC | White | Diamond | 3.0 | 2 | |

2/30 S/D AG | PVC | Apple Green | Smooth | PVC | Apple Green | Diamond | 3.0 | Antistatic | 2 |

2/38 S/P W | PVC | White | Smooth | - | Natural | Fabric | 3.8 | 2 | |

2/46 TS/P AG | PVC | Apple Green | Saw Tooth | - | Natural | Fabric | 4.6 | Antistatic | 2 |

2/50 RT/P AG | PVC | Apple Green | Rough Top1 | - | Natural | Fabric | 5.0 | No-antistic | 2 |

3/30 C/C W | Cotton | Natural | Cotton | Cotton | Natural | Cotton | 3.0 | 2ply cotton 1ply fabric | 3 |

3/40 S/P TAN | PVC | TAN Colour | Smooth | - | Natural | Fabric | 4.0 | No-antistic | 3 |

3/50 S/D AG | PVC | Apple Green | Smooth | PVC | Apple Green | Diamond | 5.0 | Antistatic | 3 |

3/40 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 4.0 | FDA | 3 |

| PU conveyor belt | |||||||||

1/08 S/P W U FDA | PU | White | Smooth | - | Natural | Impreg-nated | 0.8 | Antistatic | 1 |

2/15 M/P W U FDA | PU | White | Matt | - | Natural | Impreg-nated | 1.5 | Antistatic | 2 |

2/14 M/P PG U FDA | PU | Petrol Green | Matt | - | Natural | Impreg-nated | 1.4 | Antistatic | 2 |

2/21 S/P W U FDA | PU | White | Smooth | - | Natural | Fabric | 2.1 | Antistatic | 2 |

2/21 S/P W U KE | PU | White | Smooth | - | Natural | Fabric | 2.1 | Knife Edge Application | 2 |

2/30 S/P

W U FDA | PU | White | Smooth | - | Natural | Fabric | 3.0 | Antistatic | 2 |

Pls contact me freely if any inquiry or questions,thank you!

- Q: What's the difference between rubber and silicone?

- In choosing rubber, it requires specific performance requirements such as hardness, tensile strength, compression, deformation, wear, tear, use of the environment, etc..

- Q: What is the specific gravity of natural rubber?

- Natural rubber is composed of rubber, hydrocarbon, water, resin, protein, sugar and inorganic salts, and its specific gravity is 0.90~0.93. The natural rubber without impurities is transparent and yellowish, with good viscosity and dielectric properties, and its tensile properties are generally higher than those of synthetic rubber. Soluble in benzene, solvent naphtha, carbon disulfide, carbon tetrachloride, chloroform, turpentine, etc., but not soluble in ethanol and acetone. With halogen, oxygen, ozone, peroxide, sulfur and so on. Widely used in the manufacture of rubber products, such as tires, rubber shoes, hose, tape, wire and cable insulation materials.

- Q: Rubber Mooney value is what meaning, what is the role of

- In accordance with the provisions of the standard GB 1232 (Mooney viscosity), rotation expressed by the symbol Z100 C 1+4. Where Z rotational viscosity; 1, preheating time is 1min; 4 - rotation time is 4min; 100 C - test temperature of 100 degrees.In our country, usually with ML100 or MS100 1+4 to 1+4 DEG C said. M said L Mooney, represented by the greater trochanter, S said with a small rotor.1 preheat for 1 minutes, 4 said that the test for 4 minutes. The larger the value of Mooney viscosity, said, the plastic is widely used as a low. Index control process performance of rubber.

- Q: What are the forming methods of rubber products?

- In these methods, injection molding has the significant advantages of simplifying process, reducing the number of operators; second, reduce the energy consumption of about 10%; the production efficiency is improved by 4 ~ 7 times; improve product uniformity, stability, size precision and the qualification rate; reduce the flash, saving material and convenient operation;, low labor intensity, high degree of mechanization and automation. Therefore, in recent years, more and more attention has been paid to injection molding technology, and it has been developed rapidly in rubber products production

- Q: What is rubber damping material?

- Butyl rubber, butyl bromide and butyl chloride are the main ones!! Need to design, sell rubber products, can find me!

- Q: How to improve the hardness of rubber?

- Increasing the degree of crosslinking (increasing the dosage of vulcanizing agent and prolonging the curing time properly);Increase the dosage of reinforcing agent, or choose reinforcing agent with high structure and large specific surface area;Hardening resin, high styrene and other hardening agent;

- Q: Can the rubber surface be painted with paint?

- Rubber surface of the original jet printing pattern, etc., how to remove clean, and does not affect the appearance and rubber layer: the way is solvent oil!

- Q: How do you remove the rubber on your new slippers?

- Different types of rubber deodorant by different chemical AO and effect, can effectively remove all kinds of rubber, including all kinds of recycled rubber smell in the processing and use of rubber products, improve the level of environmental protection, applicable to all kinds of rubber molding process. The use of low odor, high efficiency, safe and non-toxic, by Ma'anshan Keli chemical technology development and production company.

- Q: What kind of rubber is suitable for waterproof aprons?

- The vulcanized rubber is a linear or branched structure, because of its low strength, little elasticity, hardening of the cold, softening of the heat, dissolution of the solvent, etc., which makes the products useless. Therefore, the rubber products must be vulcanized, deformed, meshed or of a shape structure to be of practical value.Proper vulcanization of the rubber can maintain the high elasticity of the rubber and the strength of the rubber. At the same time, in order to increase product hardness, strength, wear resistance and tear resistance, while adding inert filler in the process (such as Zinc Oxide, clay, chalk and barite etc.) and reinforcing filler (such as carbon black).

- Q: How to solve the spray of rubber products?

- For the problem of rubber surface frost spray, Siyuan shoe material company targeted to develop the corresponding treatment agent productionProduct: SY-210C series of rubber, cream, spit and yellow treatment agent, can clean and keep the original surface of rubber products thoroughlyIn two, secondary processing products, but also increase the surface adhesion of the adhesive joint.

Send your message to us

ISO Standard PVC Flat Conveyor Belt PVC Green Belt Conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords