White Green PVC Conveyor Belt PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

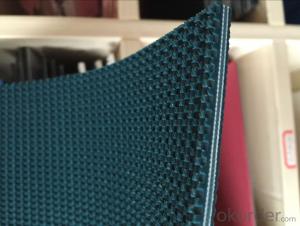

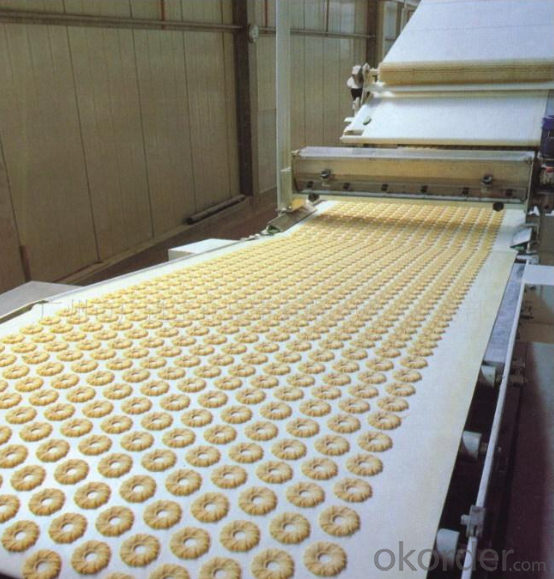

White Green PVC Conveyor Belt PU Conveyor Belt

Light Duty Conveyor Belts for food industry are excellent resistant to oil and fat, non-toxic, healthy and easy to clean. The type of belts conforms with FDA, USDA and EU regulations, can be used in many applications in the following industries: bakery, confectionary, meat and poultry, fish, fruit and vegetables, dairy, agriculture etc.

PVC/PU conveyor belt/FDA

1. material: PVC/PU

2. color: white,dark green,sky bule,etc

3. surface: smooth,matt

Features:

1)Low stretch;

2)Low maintenance;

3.Anti-static;

4)Flexible;

5.Lightweight;

6)Impervious to moisture,acids,oils,gases,sunlight;

7)Excellent fastener holding;

8)Excellent resistance to tearing,peeling and impact;

9)Endless belt splicing;

10)Special wear resistant edge design;

Specification:

1.Belt curves are developed by our company has the domestic advanced technology level of quality .

2.products.Whether driven tensioning tapered roller precision machining, or the fan belt anti-deviation

adjustment

3.techniquesare reflected in the technical and process my company on the lead position.

4.Turning belt can be made into 90 °, 180 ° or even user needs at any angle. The turning radius according to the size and weight of the object conveyor may be designed to 300MM/600MM/900MM/1200MM/1500MM/2000MM/3000MM other specifications.

5.Curve conveyor belt with the straight line, to achieve the perfect

angle transporting goods during transport can maintain its relative position

synchronized conveyor. Particularly for use in the delivery of irregular items,

such as bags, bulk, small parts.

Product Photos

For more informations,please contact us freely,thank you.

- Q: How do you prevent olive nets from causing damage to nearby structures or buildings?

- To prevent olive nets from causing damage to nearby structures or buildings, there are a few measures that can be taken. Firstly, ensuring that the nets are securely installed and properly tensioned is crucial. This will minimize the chances of the nets sagging or coming into contact with nearby structures. Additionally, regular inspection and maintenance of the nets is important to identify any potential issues, such as tears or loose attachments, which should be promptly repaired. Lastly, using protective padding or barriers between the nets and structures can provide an extra layer of protection against any accidental contact.

- Q: Do olive nets require any maintenance during the growing season?

- Yes, olive nets do require maintenance during the growing season. They need to be regularly inspected and adjusted to ensure they are properly covering the olive trees and preventing birds from accessing the fruits. Additionally, any damaged or torn portions of the nets should be repaired or replaced promptly to maintain their effectiveness.

- Q: Can olive nets be used in regions with high disease pressure?

- Yes, olive nets can be used in regions with high disease pressure. Olive nets are primarily used to protect the olives from birds and other animals, but they also provide some protection against certain diseases. However, it is important to note that olive nets alone may not provide complete protection against all diseases, and additional measures may be required to effectively combat high disease pressure in olive-growing regions.

- Q: Are there any specific techniques for spreading olive nets over large areas?

- Yes, there are specific techniques for spreading olive nets over large areas. One common technique is using mechanical devices, such as net-laying machines, which can efficiently and evenly distribute the nets. These machines are often attached to tractors and can cover large areas quickly. Another technique involves using a team of workers to manually spread the nets by hand, particularly in areas with difficult terrain or uneven ground. Both methods require careful coordination and expertise to ensure the nets are properly and uniformly spread to protect the olive trees and facilitate harvesting.

- Q: How do olive nets affect air circulation in the orchard?

- Olive nets can hinder air circulation in the orchard by creating a physical barrier that limits the movement of air. This reduced air circulation can have various impacts on the orchard, including increased humidity levels, reduced sunlight penetration, and potentially increased risk of disease or pest infestation.

- Q: What are the raw materials used in the production of plastic products?

- Cling film, plastic film are such materials, heat resistance is not strong. Usually qualified PE cling film will appear hot when the temperature exceeds 110 degrees, and will leave some plastic preparations which can not be decomposed by human body. And wrapped with plastic wrap food heating, food grease is easy to preserve the harmful substances dissolved in the film. Therefore, the food into the microwave oven before, to remove the cling film wrapped.

- Q: How does an olive net affect the overall fruit flavor in the olive grove?

- An olive net can positively impact the overall fruit flavor in an olive grove. By providing shade and protection, it helps maintain a stable microclimate, preventing excessive sun exposure and reducing stress on the trees. This can lead to better fruit quality, as the olives are less prone to drying out or becoming damaged by extreme weather conditions. Additionally, the netting acts as a barrier against pests, preventing infestations that could negatively affect the flavor of the olives. Ultimately, the use of an olive net can contribute to a more favorable and consistent flavor profile in the olives grown within the grove.

- Q: Can olive nets be used on trees with a wide canopy?

- Yes, olive nets can be used on trees with a wide canopy. Olive nets are specifically designed to cover the entire tree canopy, ensuring that the olives are caught and protected during harvesting. The nets are easily adjustable and can accommodate trees with varying sizes and shapes, including those with wide canopies.

- Q: Can olive nets be used in areas with frequent frost?

- Olive nets can be used in areas with frequent frost, but certain precautions need to be taken. The nets should be removed before the frost sets in to prevent damage to the olive trees. Additionally, using nets with a mesh size that allows air circulation can help minimize frost-related issues.

- Q: How do olive nets prevent damage from strong sunlight?

- Olive nets prevent damage from strong sunlight by providing shade and reducing the direct exposure of the olive trees to the intense rays of the sun. This helps to regulate the temperature and moisture levels around the trees, minimizing the risk of sunburn and dehydration. Additionally, the nets act as a barrier, blocking harmful ultraviolet (UV) rays that can cause damage to the leaves and fruits.

Send your message to us

White Green PVC Conveyor Belt PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords