Food Grade Biscuit PVC Belt Oil Resistant Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Grade Biscuit PVC Belt Oil Resistant Conveyor Belt

Description

PVC conveyor belt elastic, and not deformed. Selection of high-strength high-quality cotton, nylon, polyester canvas with a core made with pure ingredients made from natural rubber clean white or light-colored, non-polluting, does not affect the smell of food hygiene cover. PVC conveyor belt reasonable formula designed to meet the health indicators, color modest, lightweight and durable. PVC conveyor belt is suitable for transporting bulk, canned food industry or the food sector, packing boxes of food or food to large size 400, throughput from 1 m3 / h to 6000 m3 / h.

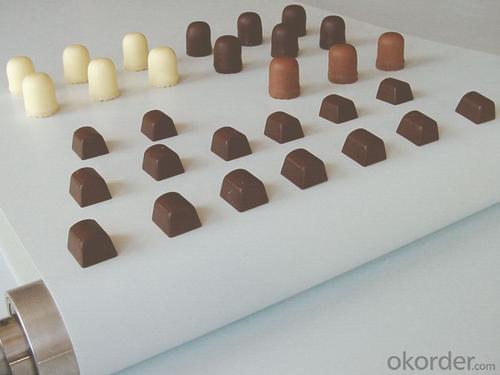

PVC food conveyor belt is widely used in the food industry or the food sector transport in bulk, canned, packed into boxes of food, cookies, candy, fruit and vegetable processing, poultry and meat processing and other related industries

Colors

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness

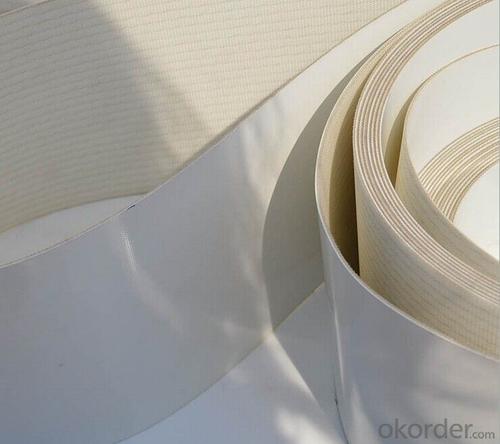

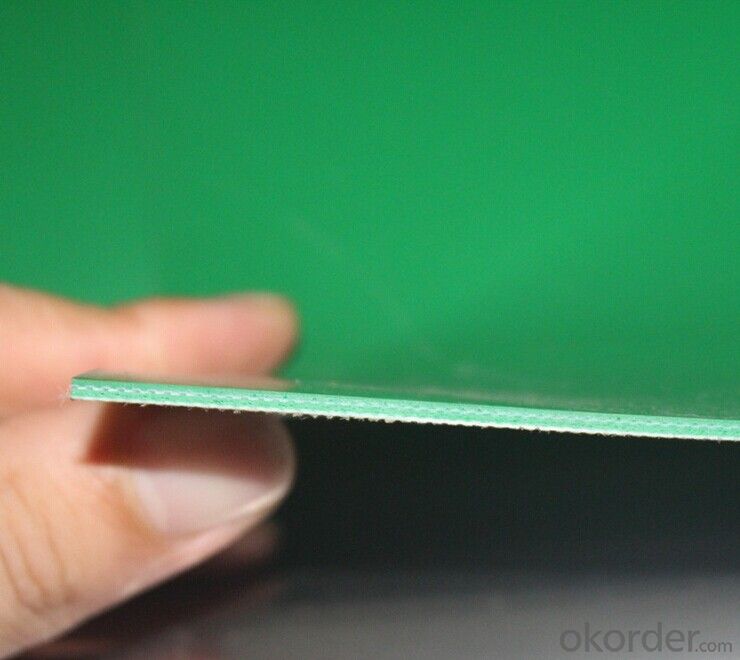

PVC (1~7mm) PU (0.8~4mm)

Appearance

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology

it can add baffle, skirt, sponge, guide bar and etc.

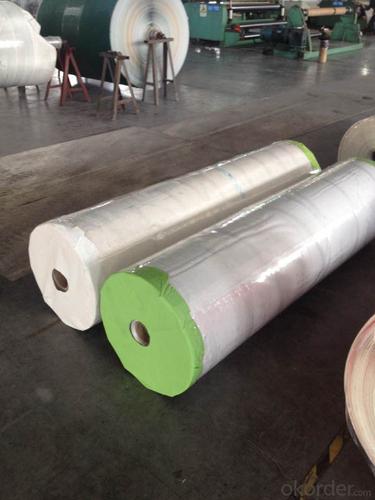

Conveyor Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Are olive nets safe for the environment?

- Yes, olive nets are generally considered safe for the environment. These nets are designed to protect the olives from birds and other pests, reducing the need for harmful chemical pesticides. They are made from biodegradable materials and can be reused or recycled, minimizing their impact on the environment. However, it is essential to use them responsibly, ensuring proper installation and removal to avoid any potential harm to wildlife or vegetation.

- Q: Can olive nets be used in both small and large-scale olive orchards?

- Yes, olive nets can be used in both small and large-scale olive orchards. Olive nets are versatile and can be adjusted to fit different orchard sizes. They are designed to protect the olives from pests and help with efficient harvesting, making them suitable for use in various orchard scales.

- Q: How does an olive net affect the overall nutrient management in the olive grove?

- An olive net can positively affect the overall nutrient management in an olive grove by providing protection from external factors that can affect nutrient levels. The net helps to prevent wind damage, which can lead to nutrient loss through leaf desiccation. It also acts as a barrier to pests and birds, reducing the risk of nutrient depletion caused by their feeding activities. Additionally, the net can help maintain a more consistent microclimate, allowing for better nutrient uptake and utilization by the olive trees. Overall, the olive net contributes to a more efficient and effective nutrient management system in the olive grove.

- Q: Can olive nets be used on olive trees in different geographical locations?

- Yes, olive nets can be used on olive trees in different geographical locations. Olive nets help protect the olives from birds and other pests, and this need exists regardless of the specific location where the olive trees are grown.

- Q: Why plastic is not environmentally friendly?

- Plastics burn easily and produce poisonous gases when they burn. For example, toluene combustion produces a small amount of polystyrene, this substance can cause blindness, vomiting and other symptoms of inhalation, PVC combustion will produce toxic gases, hydrogen chloride in combustion, is a high temperature environment, will lead to plastic decomposition of toxic components, such as benzene etc..

- Q: Are olive nets easy to repair if damaged?

- Yes, olive nets are generally easy to repair if damaged. They are often made of durable materials like polyethylene or nylon, which can withstand some wear and tear. In case of small tears or holes, they can be easily patched up using repair kits or by stitching them together. However, extensive damage may require more significant repairs or even replacement of the net.

- Q: How do olive nets prevent fruit damage during transportation?

- Olive nets prevent fruit damage during transportation by providing a protective barrier that prevents direct contact between the fruits and any external elements, such as rough surfaces or other objects. The nets act as a cushion, absorbing any impact or vibrations that may occur during transportation, thus reducing the risk of bruising or crushing the fruits. Additionally, the nets also help to maintain the integrity of the fruit by preventing them from rubbing against each other, minimizing the chances of abrasions or scratches. Overall, olive nets offer a reliable solution to ensure the safe transport of fruits and prevent any potential damage.

- Q: What is environmentally friendly engineering plastics?

- Now technically called environmentally friendly engineering plastics generally refer to halogen-free plastics,

- Q: Do olive nets come with any warranties?

- Yes, olive nets typically come with warranties that vary depending on the manufacturer or seller. It is recommended to check with the specific brand or retailer to determine the details and terms of the warranty coverage.

- Q: Can olive nets be used on olive trees grown in windy areas?

- Yes, olive nets can still be used on olive trees grown in windy areas. However, it is important to ensure that the nets are properly secured to withstand strong winds. Additionally, selecting a net with a smaller mesh size can help prevent wind damage to the olive trees and improve overall effectiveness.

Send your message to us

Food Grade Biscuit PVC Belt Oil Resistant Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords