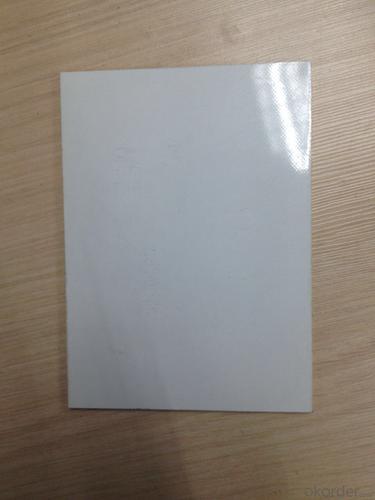

Food Industry White Food Grade PVC PU Conveyor Belting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Industry White Food Grade PVC PU Conveyor Belting

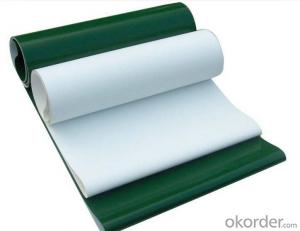

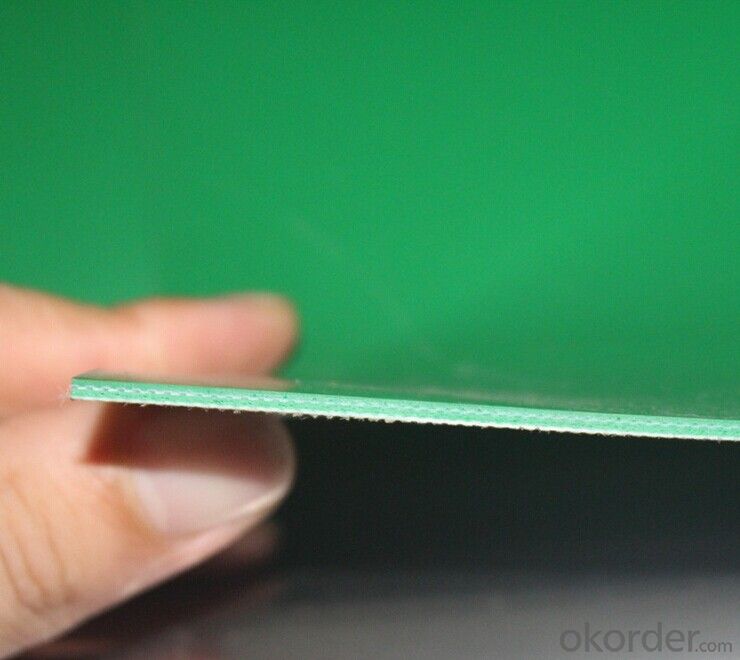

Conveyor Belt Description:

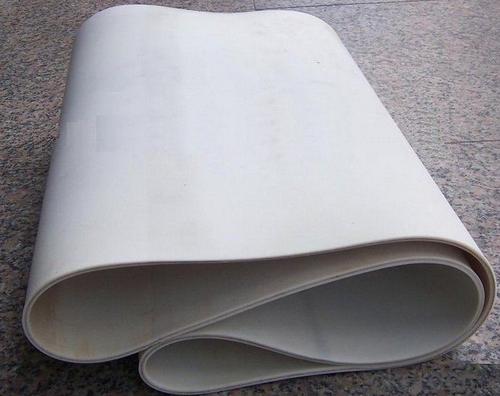

Light Duty Conveyor Belts for food industry are excellent resistant to oil and fat, non-toxic, healthy and easy to clean. The type of belts conforms with FDA, USDA and EU regulations, can be used in many applications in the following industries: bakery, confectionary, meat and poultry, fish, fruit and vegetables, dairy, agriculture etc.

Color: black, white, green, blue etc.

Thickness: 0.8~5MM customization

Maximum width: 4000MM

Strength: can be customized according to requirements

Conveyor Belt Specifications

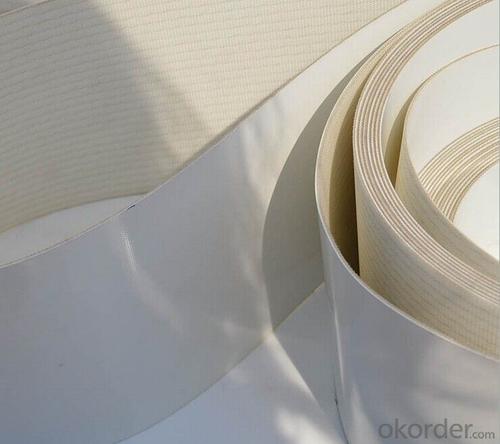

Thickness: PVC Belting (1~7mm) PU Belting (0.8~4mm)

Width: 200mm ~ 4000mm

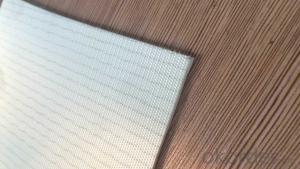

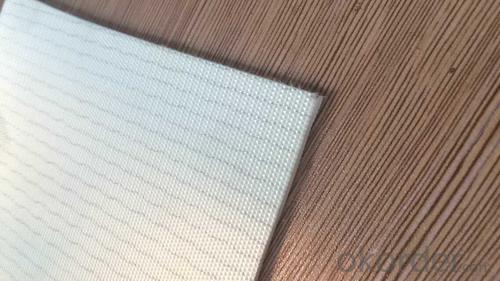

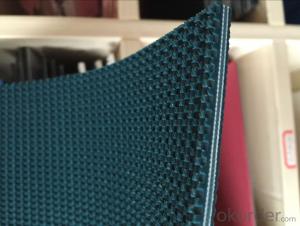

Appearance: Flat surface, diamond pattern, lawn pattern, golf pattern,etc.

Colors: Green, blue, gray, white, black, blue, dark green, transparent,etc.

Subsequent machining technology: It can add baffle, skirt, sponge, guide bar,etc.

Application:

PVC Belting: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines.

PU Belting: Most applicable to the food industry and other industries .

Working environment:

1. the working environment, conditions and conditions

2.Need to consider the time of day every day operation, the operating frequency, the service life of the belt conveyor, feeding and unloading methods.

3.Work environment, conditions: ambient temperature, outdoor or indoor, environmental requirements, mobile or fixed, telescopic requirements.

Conveyor Belt Application

Food conveyor belt

Plate conveyor belt

Printing machine of conduction band

Oil resistant conveyor belt

Knife edge conveyor belt

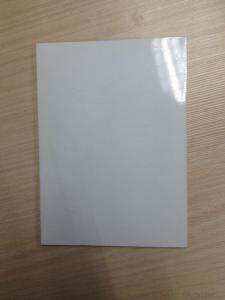

Conveyor Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: How does an olive net affect the overall crop yield in the olive grove?

- An olive net can significantly impact the overall crop yield in an olive grove. By placing the netting over the trees, it helps to protect the olives from birds, pests, and adverse weather conditions. This protection reduces the risk of damage, loss, or contamination of the olives, resulting in a higher yield. Additionally, the netting can also prevent the olives from falling prematurely, allowing them to fully ripen and mature before harvest. Therefore, an olive net positively contributes to the overall crop yield by ensuring a healthier and more abundant harvest.

- Q: How do olive nets prevent olives from being damaged by rodents?

- Olive nets prevent olives from being damaged by rodents by creating a physical barrier that rodents cannot penetrate. The tightly woven netting covers the olive tree branches and trunk, preventing access to the olives. This effectively keeps the olives safe from rodent infestation and damage.

- Q: Can olive nets be used in combination with bird repellents?

- Yes, olive nets can be used in combination with bird repellents. Olive nets serve as a physical barrier to prevent birds from accessing and damaging olive crops, while bird repellents help to deter birds from approaching the area. Using both methods together can enhance the effectiveness of bird control in safeguarding the crops.

- Q: How do olive nets prevent bird droppings from contaminating olives?

- Olive nets prevent bird droppings from contaminating olives by creating a physical barrier between the birds and the fruit. The nets are spread over the olive trees, preventing birds from accessing the olives and reducing the likelihood of droppings falling onto the fruit.

- Q: Can olive nets be used in different types of olive orchards?

- Yes, olive nets can be used in different types of olive orchards. Olive nets are designed to protect the olives from birds, insects, and other pests, and can be used in various orchard setups including traditional groves, high-density plantations, or even in pots for small-scale cultivation. The nets are versatile and can adapt to different orchard structures and sizes to ensure the safety and quality of the olives during the growing season.

- Q: Can olive nets be used on olive trees grown in arid climates?

- Yes, olive nets can be used on olive trees grown in arid climates. Olive nets are commonly used in olive orchards worldwide, including those in arid regions, to protect the olive trees and their fruit from birds and other pests. The nets help prevent damage and ensure a higher yield by providing shade and reducing water evaporation, which is particularly beneficial in arid climates where water conservation is crucial.

- Q: Can olive nets be used on trees with a dense foliage?

- Yes, olive nets can be used on trees with dense foliage. Olive nets are specifically designed to catch olives during harvest, regardless of the density of the tree's foliage. The nets are typically spread out underneath the tree, allowing olives to fall onto the net while preventing them from contacting the ground.

- Q: Can olive nets be used in areas with high wind speeds?

- Yes, olive nets can be used in areas with high wind speeds. However, it is important to ensure that the nets are properly secured and supported to withstand the strong winds. Additionally, using stronger and more durable nets specifically designed for high wind areas can provide better protection and longevity.

- Q: How does an olive net affect the overall fruit texture in the olive grove?

- An olive net affects the overall fruit texture in the olive grove by providing protection to the olives from external factors such as wind, pests, and excessive sunlight. This helps in maintaining the integrity and quality of the fruit, resulting in a smoother and more consistent texture.

- Q: Sponge does not belong to foam plastics

- There is a similarity between them, but the process is different and the uses are different.

Send your message to us

Food Industry White Food Grade PVC PU Conveyor Belting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords