PVC/PU Conveyor Belt for Food Industry White PU Conveyor Belting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC/PU Conveyor Belt for Food Industry White PU Conveyor Belting

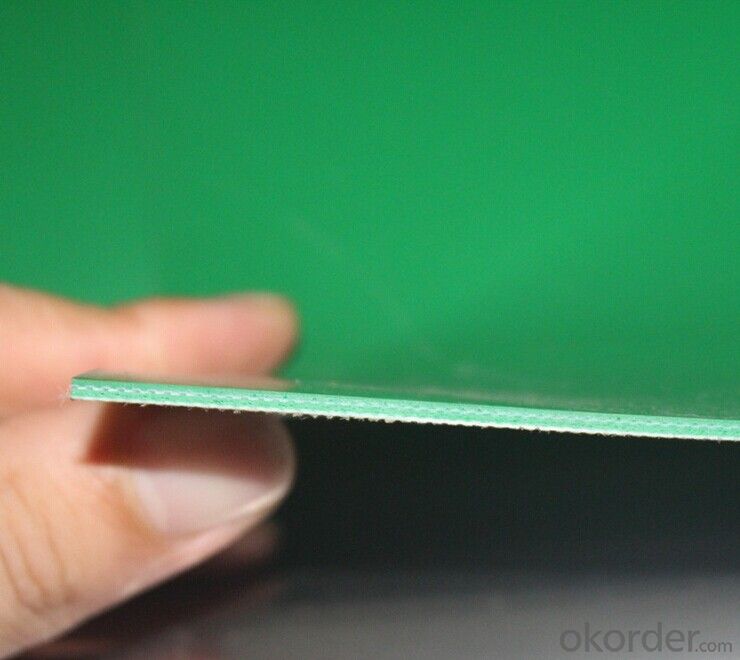

Conveyor Belt Descriptions

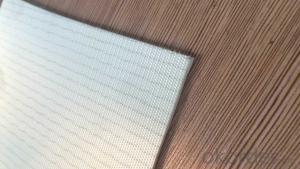

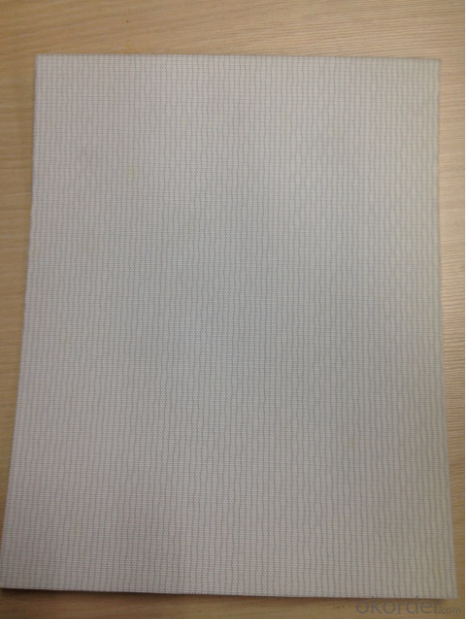

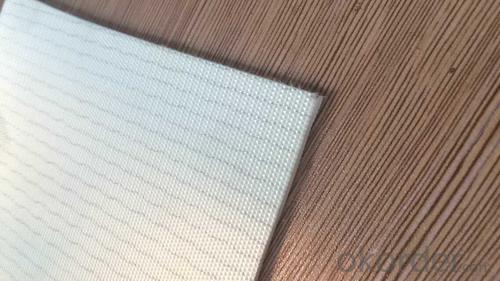

Thickness: PVC Belting (1~7mm) PU Belting (0.8~4mm)

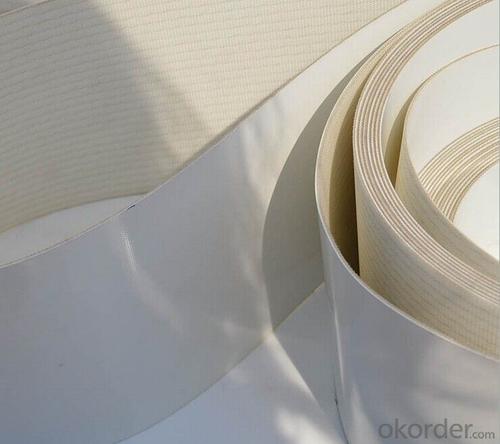

Width: 200mm ~ 4000mm

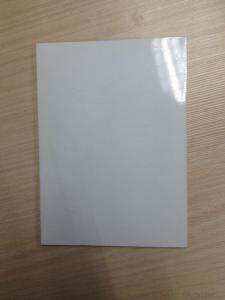

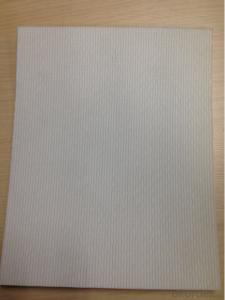

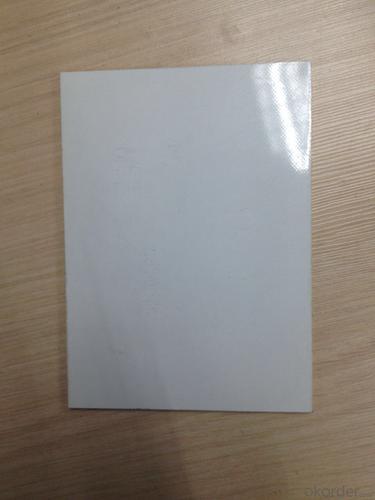

Appearance: Flat surface, diamond pattern, lawn pattern, golf pattern,etc.

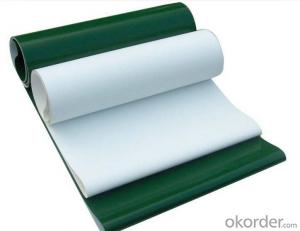

Colors: Green, blue, gray, white, black, blue, dark green, transparent,etc.

Subsequent machining technology: It can add baffle, skirt, sponge, guide bar,etc.

Application:

PVC Belting: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines.

PU Belting: Most applicable to the food industry and other industries .

Conveyor Belt Specifications

1.Belt curves are developed by our company has the domestic advanced technology level of quality .

2.products.Whether driven tensioning tapered roller precision machining, or the fan belt anti-deviation

adjustment

3.techniquesare reflected in the technical and process my company on the lead position.

4.Turning belt can be made into 90 °, 180 ° or even user needs at any angle. The turning radius according to the size and weight of the object conveyor may be designed to 300MM/600MM/900MM/1200MM/1500MM/2000MM/3000MM other specifications.

5.Curve conveyor belt with the straight line, to achieve the perfect

angle transporting goods during transport can maintain its relative position

synchronized conveyor. Particularly for use in the delivery of irregular items,

such as bags, bulk, small parts.

Working environment:

1. the working environment, conditions and conditions

2.Need to consider the time of day every day operation, the operating frequency, the service life of the belt conveyor, feeding and unloading methods.

3.Work environment, conditions: ambient temperature, outdoor or indoor, environmental requirements, mobile or fixed, telescopic requirements.

Conveyor Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Plastic long time to become sticky, how to remove?

- Plastic is polyolefin, easy to oxidize, long time to place it will become sticky.1, wipe the face oil coated, and wipe evenly, first use the nail to cut him off, and then take a wet towel, wipe off.2, use the hair dryer blow, the glue baking heat can be got down.3, with Fengyoujing rub, then try out.

- Q: Can olive nets be recycled?

- Yes, olive nets can be recycled. They are typically made of polyethylene or polypropylene, which are both widely recycled materials. However, it's important to check with your local recycling facilities to ensure they accept these types of nets. Some regions may have specific recycling guidelines for agricultural or industrial plastics.

- Q: Do olive nets come with a warranty?

- Yes, olive nets typically come with a warranty.

- Q: Can olive nets be used for olive trees in regions with limited labor availability?

- Yes, olive nets can be used for olive trees in regions with limited labor availability. Olive nets are designed to catch the olives as they fall from the trees during harvesting. By using these nets, the need for manual labor to pick the olives from the ground is significantly reduced. This makes it a practical solution for regions facing a shortage of labor. Additionally, olive nets help protect the fallen olives from being damaged and keep them clean, ensuring higher quality harvests.

- Q: How do olive nets affect pollination?

- Olive nets can potentially affect pollination by acting as a physical barrier that restricts the movement of pollinators such as bees and other insects. These nets are used to protect olive trees from pests and birds, but they can also unintentionally prevent pollinators from accessing the flowers, hindering the process of pollination. As a result, the use of olive nets may reduce the overall pollination success of olive trees, ultimately impacting their fruit production.

- Q: How do olive nets impact the natural pollination process of olive trees?

- Olive nets can have a negative impact on the natural pollination process of olive trees. The nets are often used to protect the olives from birds and insects, but they can also prevent pollinators like bees from accessing the flowers. As a result, the transfer of pollen between flowers may be limited, leading to reduced fruit set and lower overall pollination success. It is important to find a balance between protecting the olives and allowing for effective pollination to ensure optimal yields and maintain the health of the olive tree ecosystem.

- Q: What additives are used in plastics?

- The main requirements for plastic additives are: high efficiency: can effectively play its functions in the plastics processing and application. The comprehensive performance requirements should be based on the selection of additives mixing. The compatibility with synthetic resin better compatibility. The persistence: volatile in plastics processing and application process no exudation, does not migrate, dissolution. The chemical stability: no decomposition in plastics processing and application process, and the synthetic resin and other components of chemical reaction. The non-toxic, without any toxic effects on the human body. The price is low.

- Q: Can olive nets be used to reduce the risk of soil erosion in areas with high rainfall?

- Yes, olive nets can be used to reduce the risk of soil erosion in areas with high rainfall. These nets are commonly used in olive orchards to prevent soil erosion by trapping and stabilizing the soil. They act as a physical barrier that prevents rainwater from directly hitting the soil surface, reducing the impact and velocity of water flow. This helps to prevent the detachment and transportation of soil particles, thereby minimizing soil erosion. Olive nets also contribute to the conservation of moisture in the soil, improving water infiltration and reducing runoff.

- Q: Can olive nets be used for other fruit trees as well?

- Yes, olive nets can be used for other fruit trees as well. The nets are designed to protect the fruit from birds and other pests, so they can be effective for any fruit tree that faces similar threats.

- Q: Can olive nets be used for olive tree protection against herbicides?

- Yes, olive nets can be used for olive tree protection against herbicides. Olive nets provide a physical barrier that helps prevent herbicides from reaching the olive trees and causing damage. They can effectively shield the trees from herbicide drift, ensuring their protection and health.

Send your message to us

PVC/PU Conveyor Belt for Food Industry White PU Conveyor Belting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords