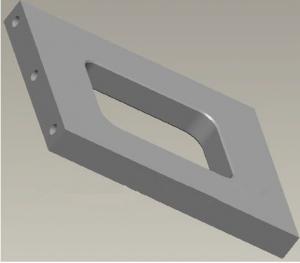

Customized Die Casting Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 200 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.FOB:US$100-1000/set

2.MOQ:1set

3.Supply Ability:200set/month

4.ISO9001/TS16949:2009

5.Product Material:steel,aluminium

Die Casting Mold ,Pressure Die Casting Mold:

Meet your "short delivery time", "high precision", "good quality", "low price" request for mould making service

1.CAD/CAE/CAM computer-aided design, simulation, manufacturing integration

2. High-quality materials to meet good quality

3.Application of advanced equipment in mould making to meet high precision

4. Application of advanced surface treatment technology to improve the life of the mould

5. High-speed milling technology significantly improve the mould processing efficiency

We can supply various die casting mould, cast molds

Production Process:

Tooling--Die Casting--CNC Machining,CNC Milling---Stamping---Painting and powder coating---Drying---Inspection---Package--Delivery

| Mold Material |

P20, C45# or Customized Steel |

| Mold Design | According to Technical Drawing or Sample |

| Mold Lifespan | 550,000shots |

Lead Time | Approximate 20 days |

| Package | Packed in plywood or Customized packing |

| Dimensions | Customized |

| Shippment | By sea, by air and by post |

| Specification | OEM,ODM Welcome |

- Q: White plastic products used for a long time will be yellow, how to do?

- There is a white board cleanser on the market, and it works well. For example, when the computer has turned yellow, it will be good to wipe with this.

- Q: Can olive nets be used in hot climates?

- Yes, olive nets can be used in hot climates. The nets help protect the olives from direct sunlight and excessive heat, which can negatively impact their quality. Additionally, the nets also aid in reducing evaporation and conserving moisture in the soil, which can be beneficial in hot and arid climates.

- Q: Are olive nets suitable for integrated pest management strategies?

- Yes, olive nets are suitable for integrated pest management strategies. Olive nets provide physical protection to olive trees, preventing pests from accessing the fruits and causing damage. This reduces the need for chemical pesticides, aligning with the principles of integrated pest management, which aim to minimize the use of harmful chemicals and promote natural pest control methods. Additionally, olive nets can also help to control the spread of diseases carried by insects.

- Q: How do you install an olive net?

- To install an olive net, start by measuring the area where you want to place the net. Next, attach sturdy support poles or anchor points around the perimeter of the area. Then, spread the netting over the support structure, making sure it is taut and covers the desired area. Finally, secure the netting in place by tying it to the support poles or using clips or ropes.

- Q: Can olive nets be used in regions with high disease pressure?

- Yes, olive nets can be used in regions with high disease pressure. Olive nets provide physical protection to the olive trees, preventing direct contact of the fruit with pathogens or pests. However, it is important to note that while olive nets can offer some level of protection, they should be used in conjunction with other disease management practices such as regular monitoring, proper sanitation, and the use of appropriate pesticides or fungicides to effectively combat diseases in high-pressure regions.

- Q: Are there any specific techniques for maintaining soil fertility when using olive nets?

- Yes, there are specific techniques that can be used to maintain soil fertility when using olive nets. One technique is to regularly monitor and adjust irrigation practices to ensure that the soil receives adequate moisture. Additionally, incorporating organic matter such as compost or manure into the soil can help improve its fertility. Crop rotation and cover cropping are also effective techniques as they help replenish nutrients in the soil and prevent erosion. Finally, using proper pruning techniques and removing excess plant material can help minimize nutrient competition and enhance nutrient uptake by the olive trees.

- Q: How do olive nets affect air circulation in the orchard?

- Olive nets can hinder air circulation in the orchard by creating a physical barrier that limits the movement of air. This reduced air circulation can have various impacts on the orchard, including increased humidity levels, reduced sunlight penetration, and potentially increased risk of disease or pest infestation.

- Q: Can olive nets be used in hilly or sloped areas?

- Yes, olive nets can be used in hilly or sloped areas. The nets are designed to be adjustable and can be secured to adapt to the terrain, allowing them to effectively cover olive trees and prevent olives from falling on uneven surfaces.

- Q: EVA plastic products poisonous?

- Non-toxic。。For example, some foaming soles are also EVA. And foam gum, too.It seems that after foaming, it is more convenient to keep warm.I used to add EVA to LDPE as a drink straw, so I'm sure it's non-toxic.

- Q: Thinner can clean plastic products?

- Although very strong volatile solvent, but some corrosion for mobile phone plastic shell, a stimulating effect on the human skin, can cause chapped skin, it is not recommended to use thinner cleaning.

1. Manufacturer Overview

| Location | Sichuan,China |

| Year Established | 2006 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2000;ISO/TS 16949 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Chongqing,Shanghai,Shenzhen |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Customized Die Casting Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 200 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords