White PVC PU Conveyor Belt in Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White PVC PU Conveyor Belt in Food Industry

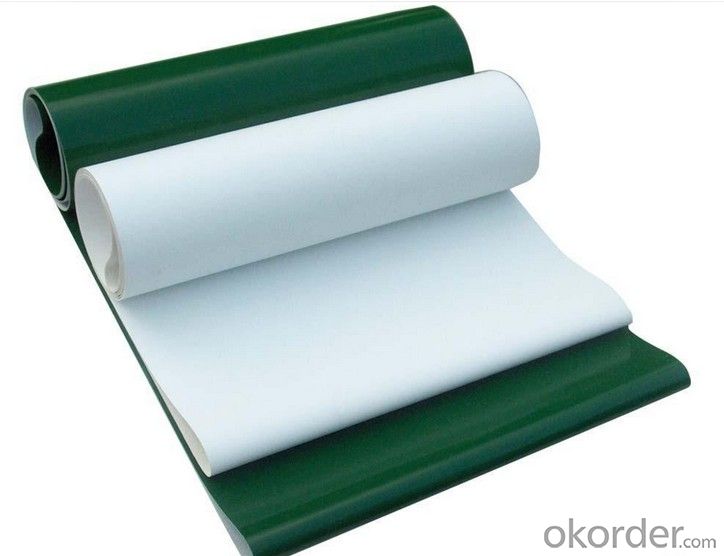

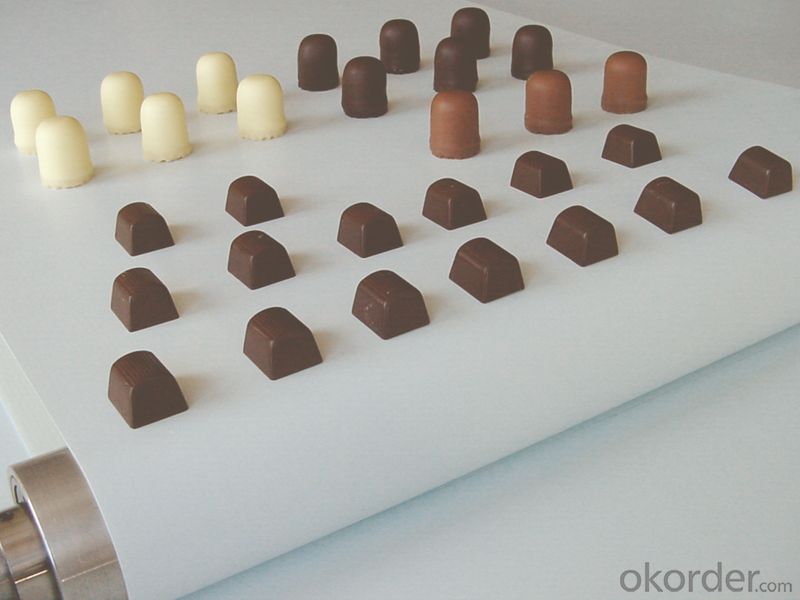

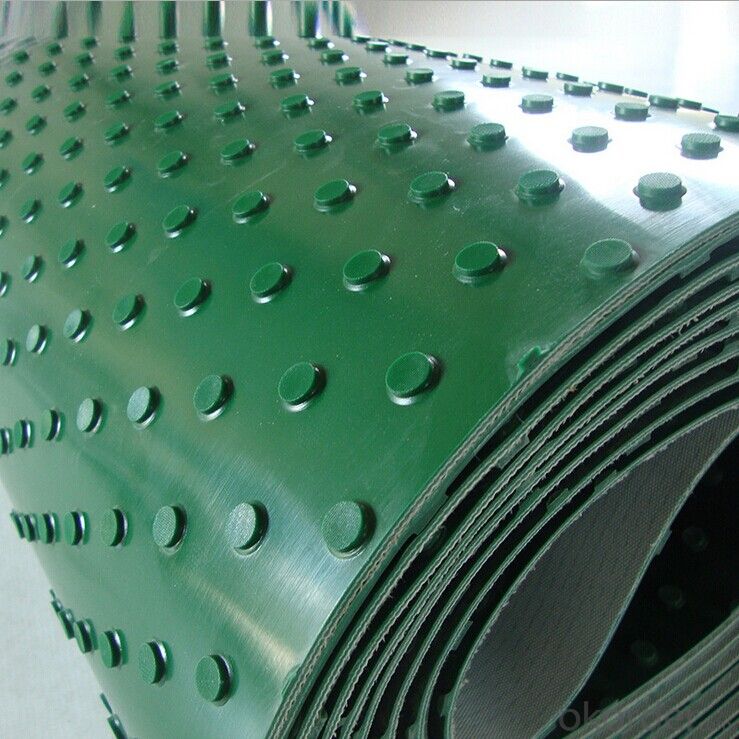

Descriptions of White PVC PU Conveyor Belt

1.mainly used for granular materials bulk conveying ascension. Such chips, peanut, sweets, dried fruits, vegetables, frozen food, vegatables,chemical and other granular or block items.

2.Hoist hopper is made of food-grade polypropylene (PP)

3.with artistic looking

4.deformation difficult

5.resistance heat and cold

6.can be used as a continuous or batch-type weighing machine or packaging production line by connecting with other facilities

7.simple maintenance

8.disassembling easy

9.convenient cleaning

10.custom-made size

Application areas of White PVC PU Conveyor Belt

Office automation equipments

Medical equipment

Packaging machinery

Swimming pool cleaning robots

Plotters

Money changers

Optical instruments

Robotic arms

Electric appliances

Vacuum systems

Vending machines

Food machinery

Textile machinery

DIY equipments

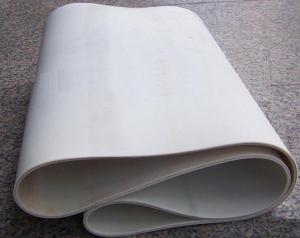

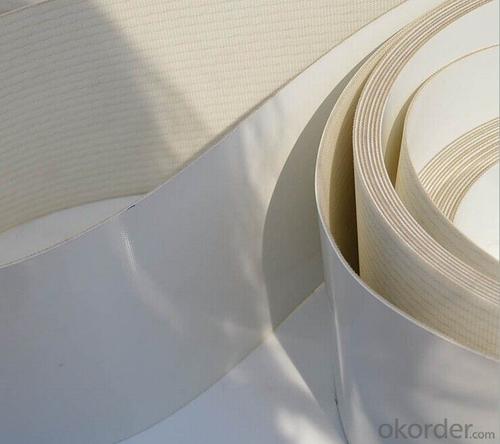

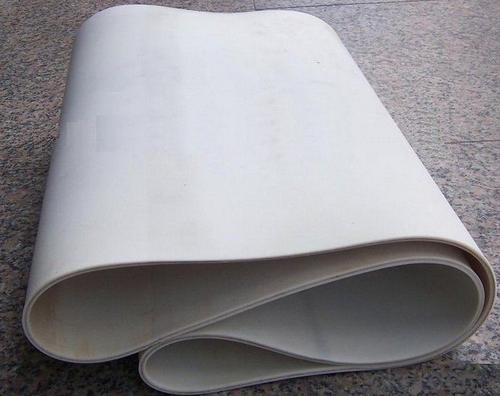

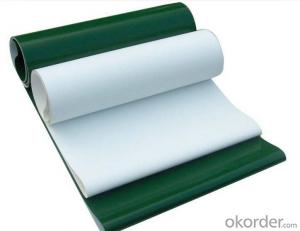

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What is the tensile strength of silicone rubber?

- The tensile strength range of silicone rubber is 3.4-14.7Mpa, depending on the formula!

- Q: What solvent is used to clear the melted rubber layer?

- Dry glue in water does not exceed 1%, in the process can be volatile, but the moisture content is too long, will not only make the rubber easy to mildew during storage, but also the impact of rubber processing, such as mixing with the agent is easy to agglomerate; easy to blister calendering and extrusion process, the bubble or a sponge the curing process etc..

- Q: How can I remove the rubber flavor on rubber products? It smells terrible

- This odor is stubborn, more difficult to solve in a short timeThe peculiar smell of a small rubber component in my car used for a week before cleaning it. If the price is not high, I suggest you change it.

- Q: How much is the recipe for Buddha's rubber?

- Rubber products were analyzed by infrared spectroscopy (FTIR), nuclear magnetic resonance (1H, NMR), mass spectrometry (MS), X diffraction analysis (XRD), ICP-MS, X fluorescence spectrometry, ion chromatography analysis, and other means. Through these testing methods can be a good solution for rubber products formulations, rubber products in the role of a detailed understanding of the more convenient for each enterprise research and development, grasp the market dynamics.

- Q: Process for producing rubber products

- Rubber elastic, lack of necessary processing plasticity properties, therefore not easy to process. In order to improve the plasticity, so the rubber mastication, so the mixing of ingredients easily dispersed in rubber, which also helps to improve the permeability of the fabric into rubber and molding in rolling and molding process. The long chain molecular degradation were called plasticity forming process of mastication. Mechanical plastication and mixing two kinds of thermoplastic plastic mixing method of rubber. Mechanical plasticization is the reduction of long chain rubber molecules at shorter temperatures through the mechanical extrusion and friction of the extruder, which changes from a high elastic state to a ductile state. Hot hot mastication is to pass into the rubber in the compressed air in the heat and oxygen under the effect of the degradation of long chain molecules to obtain shorter plasticity.

- Q: What kind of rubber products are expensive?

- Other technologies, processes, and logistics all determine the cost

- Q: How to enhance the performance of water resistant silicone rubber products

- In general, silicone rubber is almost free from the influence of free steam and moisture without pressure. The same is true when the steam is under low or moderate pressure. However, as the vapor pressure rises, the impact on the mechanical properties of the rubber becomes larger. Therefore, silicone rubber is not recommended for long-term use in situations where steam is more than 50psi.

- Q: How to make white rubber products do not yellow or delay yellowing time?

- The process of yellowing resistance is very complicated and involves many aspects, but the prevention of a certain point is not up to standard.Yellow change is mainly formed by aging. Controlling yellowing is the process of controlling aging.

- Q: The difference between plastic rubbers and rubber boots.

- Plastic and rubber are high molecular material, mainly composed of two kinds of carbon and hydrogen atoms, and some contain a small amount of oxygen, nitrogen, chlorine, fluorine, silicon, sulfur atoms, its special properties, use is also special. At room temperature, the plastic is not solid, hard, and tensile deformation of rubber hardness is not high., elastic, can be stretched, and stop pulling back to normal. This is due to differences in their molecular structure. Another difference is the plastic can be repeatedly recycled, while the rubber cannot be directly recycled, can only be processed and then reclaimed rubber, plastic and rubber. Available in the form of more than 100 to 200 degrees at 60 to 100 degrees. The morphological similarity does not include plastic rubber

- Q: How to distinguish between plastic products and rubber products, toys?

- Temperature resistance, plastic, fire easily deformation, melting, rubber will not be deformed, it will not melt

Send your message to us

White PVC PU Conveyor Belt in Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords