Flat Rubber Sealing Strips Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Flat Rubber Sealing Strips Made in China:

1. Brief Description of Flat Rubber Sealing Strips Made in China

Building door & windows; curtain walls, Automobiles, trucks, boat, railway, plane, cabinet, bridge, equipment, industrial and agriculture machines etc.

2. Main Features of Flat Rubber Sealing Strips Made in China

1. Very soft and light weight, With smooth surface

2. Ozone and chemical resistance.

3. Good elasticity and flexibility.

4. Excellent weather resistant and water resistant

5. High and low temperature resistance

6. No penetrating smell.

7. Ensure long life to use under stable temperature.

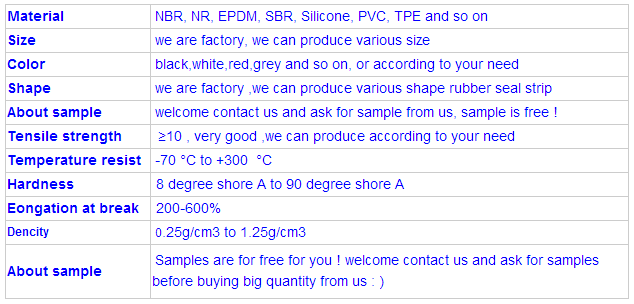

3. Main Specification of Flat Rubber Sealing Strips Made in China

4. Pictures of Flat Rubber Sealing Strips Made in China

5. FAQ

1.Q: Do you produce standard parts?

A: No, We do non-standard parts only, customised parts, OEM. According to customers design, drawing or samples.

2. Q: Your MOQ?

A: We do even prototype. No MOQ, or we can say, MOQ is 1pc.

3. Q: Your Product life time?

A: Usually, rubber seal strips can be used about 10 years.

4. Q: Your Product making time?

A: Usually, within 30 days. According to the quantity,we may refund the R$D spendings

5. Q: Your sample lead time?

A: Usually 10 - 15 days after mould's done.

- Q: What is the difference between silicone rubber and silicone rubber?

- The word language belongs to the chaos of the silica gel in above, there is no accurate way, and the types of silica can be divided into organic and inorganic silica gel, we in the life of common orthopedic medical cosmetic is divided into inorganic silica gel is a kind of amorphous chemicals into different pore structures which belongs to a liquid form of silica gel. It can be used in human tissue because it is non-toxic, no stimulation, no response to any material, has good stability, in addition to the medical industry in other industries can effectively use the strong adsorptive force so as beer silica gel, silica gel desiccant, viscose and so on

- Q: How long is the warranty period for EPDM?

- The warranty period for rubber products (EPDM) is about 1--6 months.

- Q: Rubber and metal have to be sealed before they are too strong

- The percentage difference between the first compression compression = original section diameter minus the trench size divided by the original O ring diameter O-ring compression is mainly depends on the material hardness and O-ring, O-ring if the hardness is 70 degrees, then the O-ring compression is equal to 20%. Of course, the lower the hardness of the O-ring, O-ring compression is greater, mainly used for low pressure places. Then the O-ring hardness increases the amount of compression of the O-ring is smaller, mainly used for high pressure, pressure resistance, resistance of small environment. And so on, the amount of compression can be any hardness O-ring you need.

- Q: Rubber soaked with hot water will not come out harmful substances?

- Chloroprene rubber chloroprene as the main raw material, made by homopolymerization or copolymerization of small amounts of other. Such as high tensile strength rubber, heat resistance and light resistance, aging resistance and oil resistance properties are superior to natural rubber, styrene butadiene rubber, butadiene rubber. It has a good flame resistance and excellent resistance to burning, its chemical stability is high, water resistance is good

- Q: Why does rubber burn black smoke?

- So, when rubber burns, it does not burn completely. There are many black carbon, which form black smoke

- Q: Is vulcanized sole good or rubber sole is good?

- Rubber sole refers to some students glue, wear resistance, good elasticity, also known as Dichotomanthes bottomIn general, there are advantages to each other, depending on what kind of thing you like

- Q: Rubber products are not allowed to touch oil products, but why can rubber gloves be contacted daily? What's the point?

- Most rubber materials are not resistant to oil, some rubber materials are resistant to oil, such as nitrile rubber, etc., the family commonly used detergent on rubber gloves did not affect.

- Q: What are the reasons for rubber cracking after shock absorption of rubber products?

- Shock absorber rubber suspension products, durable rubber cracking:1, rubber aging, weathering, heat resistance;

- Q: What do you pay attention to when using rubber?

- Water: the moisture content has two aspects: rubber in the humid air or rain soaked in water, easy to damage, this is because the rubber of water-soluble substances and hydrophilic components by water extraction solution, hydrolysis or other reasons caused by absorption. Especially in the water immersion and atmospheric exposure of alternating action, will accelerate the destruction of rubber. But in some cases water does not damage rubber and even retard ageing.

- Q: What kind of material does the shockproof rubber cushion usually choose? What's the hardness?

- The air tightness of butyl rubber is the best of all the rubber, is its biggest advantage, it is mainly used for tyres, although there are shock absorbing function, but dynamic flex is not ideal.

Send your message to us

Flat Rubber Sealing Strips Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords