Hot Rolled Steel Strip Coils with high quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 55 m.t.

- Supply Capability:

- 222555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil,kitchen ware

3:Architectural purpose, Milk & Food processing facilities

4:Hospital Equipment, interior Exterior decoration for building

5:Architectural purposes, escalators, kitchen ware,vehicles

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

4. On/about 1000kgs to be packed with one wooden pallet.

5. Strips can be loaded to 20'FCL without pallet if required by customer.

6. LCL shipment can also be arranged once required by the customer.

Specifications of Steel Strip Coils:

Household Appliance | Refrigerator shutter &side panels, Rice Cooker, Washer, Microwave Ovens, Freezers, Air conditions, Water Heaters, Sterilization Cabinets, Range Hoods, Computer Panels , DVD/DVB panels, TV back panel etc. |

Construction Material | Fireproof Door &Kitchen Cabinet ,Ceiling, Sanitary Unit, Elevator etc. |

Transportation | Car, Ship, Trains, Aircraft Equipment. etc. |

Education and Health Field | Electronic Writing Boards, Projection Screens, Clean Operating Rooms, etc. |

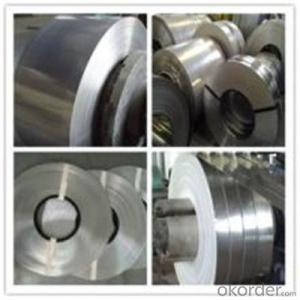

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: How are steel strips protected during transportation?

- Steel strips are protected during transportation through various methods to ensure their safety and prevent any damage. One common method is the use of protective coatings or films. These coatings act as a barrier between the steel strips and their surroundings, shielding them from moisture, dust, and other contaminants that can potentially cause corrosion or scratches. Another way to protect steel strips during transportation is by using proper packaging materials. The strips are often wrapped in plastic or paper to provide an additional layer of protection. This helps to prevent any direct contact between the strips and other objects, reducing the risk of scratches or dents. Furthermore, steel strips are often secured using straps or bands to keep them in place during transit. These straps are tightened to ensure that the strips do not move or shift, minimizing the chances of any impact or collision that could lead to damage. In addition to these measures, steel strips may also be placed in sturdy containers or pallets to further protect them from external forces. These containers provide an extra layer of protection and help to distribute any weight or pressure evenly, reducing the risk of deformation or breakage. Overall, a combination of protective coatings, proper packaging, secure strapping, and the use of containers or pallets are commonly employed to safeguard steel strips during transportation. These measures help to ensure that the strips reach their destination in optimal condition, ready for their intended use.

- Q: How are steel strips used in the production of tools?

- Due to their high strength, durability, and versatility, steel strips are essential in the production of tools. Various types of cutting tools, including saw blades, drill bits, and knives, are primarily manufactured using these strips. One of the key roles of steel strips in tool production is serving as the raw material for the tool's cutting edge. These strips are meticulously shaped and sharpened to create a precise cutting surface that effectively cuts through different materials. The hardness and toughness of steel strips make them perfectly suited for this purpose, as they can endure the intense forces and pressures during the cutting process without deforming or breaking. Furthermore, steel strips are employed in the production of tool components that demand high strength and rigidity. For instance, they are commonly utilized in constructing tool handles or frames, providing the necessary strength and stability for effective tool usage. Thanks to their malleability, the strips can be easily shaped or bent to fit the desired design and ensure an ergonomic grip for the user. Moreover, steel strips frequently find application in specialty tools such as measuring instruments or precision engineering tools. These tools require exceptional precision and accuracy, and steel strips can be precisely machined and calibrated to meet these requirements. The dimensional stability and uniformity of steel strips make them highly suitable for creating tools with consistent and reliable performance. In conclusion, steel strips are of utmost importance in tool production due to their ability to provide the necessary strength, durability, and versatility required by various cutting tools and tool components. By utilizing steel strips, the production of robust and reliable tools capable of performing a wide range of tasks in different industries and applications is ensured.

- Q: What is the standard thickness of steel strips?

- The standard thickness of steel strips can vary depending on the specific application and industry requirements. However, common standard thicknesses range from 0.015 inches (0.38 mm) to 0.25 inches (6.35 mm).

- Q: How are steel strips used in the manufacturing of pressure vessels?

- Steel strips are used in the manufacturing of pressure vessels to provide strength and structural integrity. These strips are typically rolled into cylindrical shapes and welded to form the vessel's body. The high tensile strength of steel ensures that the pressure vessel can withstand the internal pressure and external forces, making it a reliable and safe container for storing or transporting pressurized gases or liquids.

- Q: Can steel strips be used in the production of lighting fixtures?

- Yes, steel strips can be used in the production of lighting fixtures. Steel is a versatile material that can be shaped and molded into various forms, making it suitable for constructing the frames, casings, or supports of lighting fixtures. Additionally, steel's strength and durability make it a reliable choice for ensuring the longevity and stability of lighting fixtures.

- Q: What are the specifications for steel strips used in the production of fasteners?

- The specifications for steel strips used in the production of fasteners can vary depending on the specific requirements of the fastener being produced. However, some common specifications include the type of steel used (such as carbon steel or stainless steel), the thickness and width of the strip, the level of hardness required, and any specific surface finishes or coatings needed. It is important to consult the industry standards or specific fastener design guidelines to determine the precise specifications for the steel strips in question.

- Q: How are steel strips used in the production of lighting fixtures?

- Lighting fixtures for various purposes commonly incorporate steel strips. The creation of the fixture's body or housing is one of the primary applications for steel strips in lighting fixture production. To establish the structure of the lighting fixture, steel strips are frequently shaped, bent, or molded into the desired form. This ensures durability, strength, and stability, enabling the fixture to withstand the weight of its components and external forces. Moreover, steel strips can also be employed in the production of brackets or mounting plates, which secure the lighting fixture to the ceiling or wall. These brackets are crucial for proper installation and positioning, guaranteeing the fixture remains securely fixed in place. In certain instances, steel strips can serve as decorative elements in lighting fixture design. They can be fashioned into intricate patterns, curves, or other designs, enhancing the fixture's aesthetic appeal. Furthermore, steel strips may be utilized to manufacture reflectors or diffusers that regulate the direction and intensity of the emitted light. These components are vital for achieving the desired lighting effect and can be customized to meet specific requirements. Overall, steel strips fulfill a vital role in lighting fixture production, providing structural support, decorative elements, and functional components. Ultimately, this contributes to the overall quality and functionality of the product.

- Q: Are steel strips used in the production of metal brackets and supports?

- Steel strips have a common usage in the production of metal brackets and supports. These components benefit from the strength, durability, and stability that steel strips provide. Their application is often seen in situations that demand a high load-bearing capacity. Furthermore, steel strips are easily shaped, cut, and welded, which makes them suitable for different bracket and support designs. Moreover, steel strips exhibit outstanding resistance to corrosion, which makes them an excellent choice for applications in outdoor or harsh environments.

- Q: How are steel strips coated with tin?

- Steel strips are coated with tin using a process called electroplating. In this process, the steel strips are immersed in an electrolyte solution containing tin salts. A direct current is then applied to the steel strips, causing the tin ions in the solution to be attracted to the steel surface. This forms a thin layer of tin on the steel, providing it with a protective coating.

- Q: How are steel strips used in the production of metal fences?

- Steel strips are used in the production of metal fences as they are cut and shaped to form the framework and structure of the fence. These strips provide strength, durability, and support to the overall fence design, ensuring a long-lasting and secure boundary.

Send your message to us

Hot Rolled Steel Strip Coils with high quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 55 m.t.

- Supply Capability:

- 222555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords