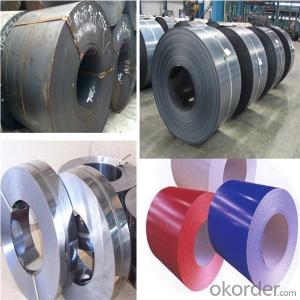

Hot Rolled/Cold Rolled Steel Strip Band Steel Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Hot Rolled/Cold Rolled Steel Strip Band Steel Made In China at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled/Cold Rolled Steel Strip Band Steel Made In China are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled/Cold Rolled Steel Strip Band Steel Made In China are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Spring steel is divided into two types, one is alloy spring steel, and other one is carbon spring steel.

Alloy spring steel is a type that is used for manufacturing springs and other elastic parts. Spring steel should have high elastic limit and ratio of yield strength and tensile strength to make sure that the springs obtain enough power of elastic deformation and can bear much load.

Types of alloy spring steel: Si-Mn spring steel, Si-Cr spring steel, Cr-Mn Spring steel, Cr-V spring steel and so on.

Specification of Spring Steel Strip

-Material: 50CrVA

-Standard: GB/T 1222-2007

-Type: Spring Steel

Chemical Composition:

C | Si | Mn | S |

0.26~0.34 | 0.17~0.37 | ≤0.40 | ≤0.030 |

P | Cr | Ni | Cu |

≤0.030 | 2.00~2.50 | ≤0.35 | ≤0.25 |

V | W | ||

0.50~0.80 | 4.00~4.50 |

Mechanical Properties:

-Yield Strength σs (MPa): ≥1470 (150)

-Elongation δ10(%):≥7

-Hardness:

1, Hot rolled + Heat treatment, ≤321HB

2, Cold drawn + Heat treatment: ≤321HB

-Impact Power: ≥40

Norm of heat treatment:

1, Quenching: 1050℃~1100℃.

2, Cooled by oil.

3, Tempering: 600℃±50℃.

Usage/Applications of Spring Strip Steel:

-Due to the elements W, Cr and V, this type of spring steel obtain pretty high hardenability and nice mechanical properties under room temperature and high temperature. The tempering stability and hot workability are good.

-Being used under the state of quenching and high temperature tempering. It’s usually used as heat-resisting springs with working temperature below 500℃, like main secure valve spring of furnace and turbine steam seal leaf springs.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

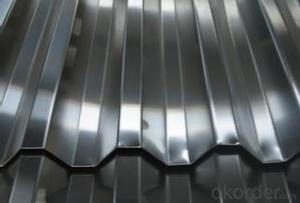

- Q: How are steel strips used in the production of metal roofing?

- Steel strips are used in the production of metal roofing as they are commonly used as the base material for the roof panels. These strips are cold-rolled and coated with protective layers to enhance durability and resistance to corrosion. They are then formed into roofing panels using various techniques like roll forming or stamping. Steel strips provide strength, stability, and longevity to the final metal roofing product, making it an excellent choice for both residential and commercial applications.

- Q: Are steel strips suitable for the manufacturing of pharmaceutical equipment?

- Yes, steel strips are suitable for the manufacturing of pharmaceutical equipment. Steel is a durable and strong material that provides the necessary strength and stability required for pharmaceutical equipment. It is also resistant to corrosion and can withstand harsh conditions, making it an ideal choice for ensuring the safety and longevity of pharmaceutical equipment. Additionally, steel strips can be easily shaped and molded into various forms, allowing for customization and versatility in the manufacturing process.

- Q: What are the common edge burr tolerances for steel strips?

- The common edge burr tolerances for steel strips typically range from 0.005 to 0.030 inches, depending on the specific application and industry standards.

- Q: How are steel strips used in the production of electrical motors?

- Steel strips are used in the production of electrical motors for various purposes such as manufacturing the motor's core laminations, which play a crucial role in reducing energy losses and increasing efficiency. The steel strips are typically shaped and stacked to create the laminations, providing a low-resistance path for the magnetic flux generated within the motor. Additionally, the steel strips provide mechanical strength and stability to the motor, ensuring its durability and proper functioning.

- Q: What are the surface finishing techniques for steel strips?

- There are several surface finishing techniques that can be employed for steel strips, depending on the desired final product and its specific requirements. Some of the commonly used surface finishing techniques for steel strips include: 1. Pickling: This technique involves the use of an acid solution to remove any oxide scale or impurities from the steel strip's surface. Pickling helps in improving the strip's corrosion resistance and prepares it for further processing. 2. Electroplating: It is a process wherein a thin layer of metal is deposited onto the steel strip's surface using an electrolytic bath. Electroplating can enhance the appearance of the strip, improve corrosion resistance, and provide additional properties such as increased hardness or conductivity. 3. Galvanizing: This technique involves coating the steel strip with a layer of zinc to provide protection against corrosion. Galvanizing is commonly used in applications where the steel strip will be exposed to harsh environments. 4. Painting: Applying a layer of paint onto the steel strip's surface can provide both aesthetic appeal and protection against corrosion. Different types of paint coatings can be used, depending on the specific requirements of the application. 5. Grinding and Polishing: These techniques involve the use of abrasive materials to remove any imperfections or roughness from the steel strip's surface. Grinding and polishing can provide a smooth and reflective finish to the strip, which is desirable in certain applications such as decorative or reflective surfaces. 6. Coating: Various types of coatings, such as powder coatings or organic coatings, can be applied to the steel strip's surface to provide protection against corrosion, enhance appearance, or provide specific functional properties. 7. Heat Treatment: Certain heat treatment processes, such as annealing or tempering, can be employed to modify the surface properties of the steel strip. These processes can improve hardness, strength, or other mechanical properties of the strip's surface. It is important to note that the choice of surface finishing technique for steel strips depends on factors such as the desired final properties, application requirements, cost considerations, and environmental impact.

- Q: How are steel strips protected against UV radiation?

- Steel strips are commonly protected against UV radiation through the application of coatings or paints that contain UV-resistant agents. These coatings create a barrier between the steel surface and the harmful UV rays, preventing the strips from undergoing degradation or discoloration caused by prolonged exposure to sunlight.

- Q: How are steel strips used in the defense industry?

- Steel strips are utilized in various ways in the defense industry, such as for manufacturing armored vehicles, tanks, and military aircraft. These strips are commonly used to reinforce and strengthen critical components, including structural parts, armor plates, and bulletproof panels. Additionally, steel strips are crucial for producing weapons, ammunition, and other defense equipment that require high strength and durability.

- Q: How are steel strips coated with paint or powder?

- Steel strips can be coated with paint or powder through a process called coil coating, where the strip is unwound from a coil and passed through a series of cleaning, pretreatment, and coating stations. In the case of paint, the strip is first cleaned and treated to ensure proper adhesion, then the paint is applied using rollers, brushes, or sprayers. For powder coating, the strip is electrostatically charged and the powder is sprayed onto the surface, then cured in an oven to create a durable coating.

- Q: How are steel strips processed for soundproofing?

- There are several ways to process steel strips for soundproofing. One method involves applying a layer of sound-absorbing material, like foam or rubber, to the strip. This material helps to reduce noise transmission by dampening and absorbing sound vibrations. The steel strip is typically coated or bonded with the sound-absorbing material to ensure a secure attachment. Another approach is to use a technique called constrained layer damping (CLD), which involves applying a viscoelastic layer to the steel strip. This layer converts sound energy into heat, effectively dissipating vibrations and reducing noise. Materials like butyl rubber are commonly used for the viscoelastic layer because of their excellent damping properties. In addition, surface treatments can be applied to the steel strips to enhance their soundproofing capabilities. For example, perforations or microperforations can be made on the surface to disrupt sound waves and reduce their transmission. This technique is often used in architectural applications, like soundproofing ceilings or walls. Furthermore, the shape and dimensions of the steel strips can also contribute to soundproofing. Using thicker and wider strips increases their mass, which helps to block sound transmission. Additionally, the design of the strips can incorporate features such as corrugations or ridges, which disrupt sound waves. Overall, the processing of steel strips for soundproofing involves various techniques, including adding sound-absorbing materials, applying viscoelastic layers, surface treatments, and optimizing the shape and dimensions. These methods aim to minimize noise transmission and create a quieter environment.

- Q: How are steel strips processed for notching?

- Steel strips are processed for notching by using specialized machinery that cuts V-shaped notches into the strips. This process involves feeding the steel strips through the machine, where a cutting tool applies pressure to create precise notches according to the desired specifications.

Send your message to us

Hot Rolled/Cold Rolled Steel Strip Band Steel Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords