Hot and Cold Rolled Steel Strip Coils with High Quality in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 122 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Steel Strip Coils:

Steel strips is one of our main products that is widely used in making band saw blade & other blades to cut paper, weed, etc.

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

Specifications of Steel Strip Coils:

Our Products are packed and labeled according to rigorous internal regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product and quality information.

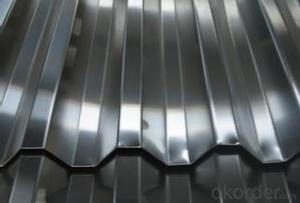

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: What is the yield strength of steel strips?

- The yield strength of steel strips differs based on the unique grade and composition of the steel. Typically, steel strips possess a yield strength ranging from 210 to 550 megapascals (MPa). Yield strengths surpassing 1000 MPa are achievable in higher strength steels like high-strength low-alloy (HSLA) or advanced high-strength steel (AHSS). It should be emphasized that the specific yield strength will also be influenced by variables like the thickness and processing of the steel strips.

- Q: Can steel strips be used in the manufacturing of agricultural equipment?

- Yes, steel strips can be used in the manufacturing of agricultural equipment. Steel strips are commonly used in the fabrication of various components and parts for agricultural machinery due to their strength, durability, and ability to withstand harsh conditions. These strips can be shaped, welded, and formed into different structures such as brackets, frames, or supports, providing stability and reliability to agricultural equipment.

- Q: How are steel strips protected against rust and corrosion?

- Steel strips are protected against rust and corrosion through a variety of methods. One common method is the application of a protective coating on the surface of the steel. This can be done through processes such as galvanizing or painting. Galvanizing involves coating the steel with a layer of zinc, which acts as a sacrificial layer. Zinc is more reactive than steel, so it corrodes first, protecting the steel underneath. This process is highly effective in preventing rust and corrosion, especially in outdoor or high-humidity environments. Painting is another widely used method of protection. A layer of paint acts as a barrier between the steel and the surrounding environment, preventing moisture and oxygen from coming into direct contact with the steel surface. The paint can be formulated with corrosion-resistant additives to provide even greater protection. In addition to coatings, steel strips can also be protected through the use of corrosion inhibitors. These are chemical compounds that are applied to the steel surface and form a protective layer. Corrosion inhibitors work by either passivating the steel surface, making it less reactive, or by forming a protective film that prevents the penetration of corrosive substances. Proper storage and handling of steel strips is also crucial in preventing rust and corrosion. This includes keeping the strips in a dry environment, away from moisture and corrosive substances. Regular cleaning and maintenance, such as removing any dirt or debris that may accumulate on the surface, can also help prolong the lifespan of the steel and prevent corrosion. Overall, a combination of protective coatings, corrosion inhibitors, and proper storage practices is essential in ensuring the long-term protection of steel strips against rust and corrosion.

- Q: How are steel strips tested for hardness?

- Steel strips are typically tested for hardness using a method called the Rockwell hardness test. This involves applying a specific amount of force to the surface of the steel strip using a diamond or carbide ball indenter, and then measuring the depth of the indentation. The hardness value is determined based on the depth of the indentation, providing an accurate measure of the steel strip's hardness.

- Q: How are steel strips annealed for improved properties?

- Steel strips are annealed to improve their properties through a process called annealing. Annealing involves heating the steel strips to a specific temperature and then gradually cooling them down. This thermal treatment helps to remove any internal stresses within the steel, making it softer and more ductile. To anneal steel strips, they are typically heated to a temperature slightly above the critical temperature, which is the temperature at which the steel undergoes a phase transformation. This temperature may vary depending on the type of steel being annealed. Once the desired temperature is reached, the steel strips are held at that temperature for a specific duration to allow for the desired changes to occur. This duration may also vary depending on the thickness and composition of the steel. After the soaking period, the steel strips are slowly cooled down in a controlled manner. This slow cooling process, also known as furnace cooling, allows the steel to undergo a transformation called recrystallization. Recrystallization helps to refine the grain structure of the steel, making it more uniform and reducing any internal defects. The annealing process improves the properties of steel strips in several ways. It reduces the hardness and brittleness of the steel, making it easier to form and shape. It also increases the ductility and toughness of the steel, making it less prone to cracking or breaking under stress. Additionally, annealing helps to improve the machinability and weldability of the steel, making it easier to work with during various manufacturing processes. In conclusion, annealing steel strips is a crucial step in improving their properties. By carefully controlling the heating and cooling process, steel strips are made softer, more ductile, and less prone to defects. This enhances their overall performance and makes them more suitable for various industrial applications.

- Q: What are the dimensions of a typical steel strip?

- The dimensions of a typical steel strip can vary depending on its intended application and industry standards. However, common dimensions for steel strips range from 0.5 inches to 12 inches in width and 0.005 inches to 0.25 inches in thickness. The length of a steel strip is typically determined by the coil it is supplied in, which can vary from several hundred to several thousand feet long. It is important to note that these dimensions are general guidelines and may vary based on specific requirements and manufacturing processes for different applications.

- Q: How are steel strips tested for coating thickness?

- Steel strips are tested for coating thickness using various methods and instruments. One of the most common methods is the magnetic induction method, also known as magnetic pull-off method. In this method, a handheld gauge with a magnetic probe is used to measure the magnetic attraction between the probe and the steel strip. The coating thickness is then calculated based on the strength of the magnetic attraction. Another commonly used method is the eddy current method. This method utilizes a handheld gauge with an eddy current probe. The probe generates an alternating magnetic field that induces eddy currents in the steel strip. By measuring the impedance of these eddy currents, the coating thickness can be determined. Ultrasonic thickness gauges are also used to test coating thickness on steel strips. These gauges emit high-frequency sound waves that penetrate the coating and reflect back from the steel strip. By measuring the time it takes for the sound waves to travel and return, the coating thickness can be calculated. In addition to these methods, there are also destructive tests that involve cutting a small section of the steel strip and measuring the coating thickness using microscopy or other specialized equipment. However, destructive tests are typically used as a last resort or for quality control purposes. Overall, the testing of coating thickness on steel strips involves a combination of non-destructive methods such as magnetic induction, eddy current, and ultrasonic testing, along with occasional destructive tests for verification and quality control.

- Q: Can steel strips be used in the production of electronics?

- Yes, steel strips can be used in the production of electronics. They are often used as a base material for circuit boards and as a structural component in electronic devices due to their strength, durability, and ability to dissipate heat effectively.

- Q: How are steel strips processed for chemical resistance?

- Steel strips are typically processed for chemical resistance through a surface treatment method known as passivation. This involves exposing the steel strips to an oxidizing agent, such as nitric acid or chromic acid, which removes iron contaminants from the surface and forms a protective oxide layer. This oxide layer acts as a barrier against corrosive chemicals, enhancing the steel's resistance to chemical reactions and preventing the formation of rust or other forms of corrosion.

- Q: Can steel strips be bent or formed into specific shapes?

- Yes, steel strips can be bent or formed into specific shapes through various methods such as cold bending, hot bending, or using specialized machinery like presses and rollers.

Send your message to us

Hot and Cold Rolled Steel Strip Coils with High Quality in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 122 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords