Steel Coil In Slip Good Quality Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Description

Narrow strip steel is below 650 mm steel, the product in a bar or roll supplies.Due to the edges of the strip shape after rolling strip steel is more suitable for welding after the slitting, so much for welded pipe, metal construction and daily necessities such as blank.With method of continuous production of narrow strip steel by using many sets of vertical roll mill and obtain good shape of edge, the edge shearing defects such as flash and burr, thus ensuring welding performance.It than with wide strip slitting machine cut into strip saves a vast amount of equipment, so it is more suitable for simple equipment of small and medium-sized enterprises.

2. Main Features

Hot rolled narrow strip in the old open-train mill in the production process of flat steel production process is similar in general section mill;In the new continuous mill production, its technological process and equipment structure form basically similar with wide strip production technology for HSM.Hot rolled narrow strip steel billet for slab and billet used in the production of two.From increasing production capacity and simplify the production process, the slab is good, but must be sufficiently workshop or add big mill to provide.When using billet as blank, although production was lower, but the source is more easily, for small and medium-sized enterprises, have simplified equipment and the advantages of independent production.The main factors influencing the quality of hot rolled narrow strip steel product with billet defects, rolling temperature, rolling tension and roll wear and surface roughness, etc

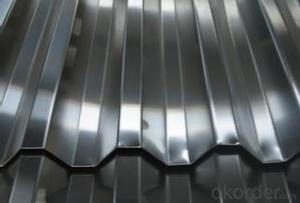

3. Excellent Product Image

4. Application

The classification of strip steel by the material divided into two categories, ordinary steel strip and high quality steel strip;According to the processing method is divided into hot and cold rolling.The purpose of strip steel is widely used in production of welded steel pipe, cold bending steel billet, manufacturing bicycle frame and wheels

5. FAQ

1.Q: Do you have attended any exhibition?

A: We almost go to Canton Fair and Overseas Exhibitions every year.

2. Q: How to guarantee the quality of the products?

A: We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. Q: How long can we receive the product after purchase?

A: Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

Why choose us?

Pre-sale Service

1. Sample can be offered with sample charge and courier fee by buyer's side.

2. We have full stock,and can deliver within short time.Many styles for your choices.

3. OEM and ODM order are accepted, Any kind of logo printing or design are available.

4. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you

5. All of our products are produce by our professional workman and we have our high-work-effect foreign trust-worthy sales team.

6. We have 18 years' experience of design, manufacture and sell lingerie, we cherish every order from our honor.

After you choose

1. Count the most efficient shipping cost and make invoice to you at once.

2. Check quality again, then send out to you at 1-2 working day after your payment.

3. Email you the tracking no, and help to chase the parcels until it arrive you.

- Q: What are the alloying elements found in steel strips?

- The composition of alloying elements in steel strips varies depending on the grade and intended use of the steel. However, several alloying elements commonly found in steel strips are carbon, manganese, silicon, phosphorus, sulfur, chromium, nickel, and molybdenum. Of these elements, carbon is the most crucial as it provides strength and hardness to the steel. Manganese is frequently added to improve the hardenability and tensile strength of the steel strips. Silicon is utilized to enhance the steel's resistance to oxidation and enhance its electrical properties. Although phosphorus and sulfur are usually present in small amounts, they can affect the machinability and brittleness of the steel. Chromium is incorporated to boost the steel's corrosion resistance and its strength at elevated temperatures. Nickel is employed to enhance the toughness and ductility of the steel, particularly in low-temperature applications. Molybdenum is often added to increase the steel's strength, hardness, and resistance to corrosion. Depending on the desired properties of the steel strips, other alloying elements such as vanadium, titanium, copper, and aluminum may also be present. In summary, the alloying elements in steel strips are meticulously chosen to achieve specific mechanical, physical, and chemical properties, making the steel suitable for a wide range of applications in various industries.

- Q: How are steel strips cold rolled?

- Steel strips are cold rolled by passing them through a series of rollers at room temperature, which apply pressure to reduce the thickness and improve the surface finish of the strips. This process not only increases the strength and hardness of the steel but also enhances its dimensional accuracy and overall quality.

- Q: Can steel strips be used in the manufacturing of cutting tools?

- Yes, steel strips can be used in the manufacturing of cutting tools. Steel strips are commonly used in the production of various types of cutting tools such as saw blades, knives, shears, and drills. The properties of steel, such as its high strength, durability, and resistance to wear and corrosion, make it an ideal material for cutting tools. Steel strips can be easily formed and shaped into the desired cutting tool design, and they can also be hardened and tempered to enhance their cutting performance. Additionally, steel strips can be coated or treated with various materials or coatings to further improve their cutting efficiency and prolong their lifespan. Overall, steel strips offer a reliable and versatile option for the manufacturing of cutting tools.

- Q: What are the different types of steel strips available?

- There are several different types of steel strips available, each with its own unique properties and uses. Some common types include: 1. Carbon steel strips: These are made from iron and carbon, and are the most common type of steel strip. They are known for their strength and durability, and are used in a wide range of applications such as construction, automotive manufacturing, and electrical equipment. 2. Stainless steel strips: These are made from a combination of iron, chromium, and other elements. They have excellent corrosion resistance and are often used in applications where hygiene and cleanliness are important, such as in the food and beverage industry. 3. Galvanized steel strips: These are carbon steel strips that have been coated with a layer of zinc to protect against corrosion. They are commonly used in outdoor applications, such as fencing, roofing, and automotive parts. 4. High-strength low-alloy (HSLA) steel strips: These are carbon steel strips that have been alloyed with small amounts of other elements, such as manganese, vanadium, or niobium. This improves their strength and toughness, making them ideal for applications that require high strength-to-weight ratios, such as in the construction of bridges and buildings. 5. Electrical steel strips: These are special types of steel strips that have been specifically designed for use in electrical equipment, such as transformers and motors. They have low magnetic losses and high electrical resistance, making them efficient for use in these applications. These are just a few examples of the different types of steel strips available. The specific type of steel strip chosen will depend on the desired properties and intended use of the product.

- Q: What are the different surface patterns available for steel strips?

- There are several different surface patterns available for steel strips, including plain, smooth, textured, embossed, brushed, and patterned surfaces.

- Q: What are the different methods for embossing steel strips?

- There exists a variety of techniques for embossing steel strips, each possessing its own merits and applications. 1. Roll embossing remains the most prevalent method, involving the passage of the steel strip through a series of rolls with engraved patterns. The rolls exert pressure on the strip, resulting in the desired embossed design. Industries such as automotive, construction, and decorative applications widely employ roll embossing. 2. Heat embossing entails heating the steel strip before pressing it onto a patterned die. The heat softens the metal, enabling it to conform to the shape of the die. Heat embossing is particularly advantageous for intricate or elaborate designs that prove challenging to achieve through roll embossing. 3. Laser embossing represents a non-contact approach, utilizing a laser beam to create the embossed pattern on the steel strip. The laser selectively removes material from the surface, generating the desired design. Laser embossing offers remarkable precision and flexibility, rendering it suitable for complex and customized patterns. 4. Press embossing, also referred to as stamping, necessitates the use of a hydraulic or mechanical press to exert force on the steel strip against a die. The die possesses the desired engraved pattern, and the pressure from the press transfers the pattern onto the strip. Press embossing finds common usage in large-scale production and facilitates deep and uniform embossing. 5. Photochemical etching involves the application of a photoresist onto the steel strip, followed by exposure to ultraviolet light through a patterned mask. The exposed areas are chemically etched away, leaving behind the embossed design on the strip. Photochemical etching permits intricate patterns and is frequently employed for decorative or artistic purposes. Each method exhibits its own advantages and limitations, with the selection of a particular technique dependent on factors such as the desired design, production volume, precision requirements, and cost considerations.

- Q: How are steel strips measured and classified?

- Steel strips are measured and classified based on their dimensions, thickness, and mechanical properties. The measurement of steel strips typically involves three main parameters: width, thickness, and length. The width refers to the distance between the two edges of the strip, while the thickness is the distance between the top and bottom surfaces. The length, on the other hand, refers to the overall size of the strip. Steel strips are commonly classified based on their thickness. They can be categorized into thin, medium, or thick strips. Thin strips usually have a thickness of less than 3 mm, medium strips range from 3 mm to 10 mm, and thick strips have a thickness exceeding 10 mm. This classification is important as it determines the suitability of the steel strip for various applications, such as in the automotive, construction, or manufacturing industries. Moreover, steel strips can also be classified based on their mechanical properties. These properties include tensile strength, yield strength, elongation, hardness, and other relevant characteristics. These properties help determine the strength and durability of the steel strip, making it suitable for specific applications. For example, high tensile strength strips are commonly used in industries that require robust materials, while strips with good formability are preferred in industries that require complex shaping or bending. In addition to dimensions and mechanical properties, steel strips may also be classified based on their surface finish. This can include factors such as the presence of a protective coating or the level of smoothness. The surface finish is important as it impacts the appearance, corrosion resistance, and overall quality of the steel strip. Overall, the measurement and classification of steel strips involve considering dimensions, thickness, mechanical properties, and surface finish. Understanding these parameters is crucial in selecting the appropriate steel strip for a specific application, ensuring optimal performance and durability.

- Q: Can steel strips be used in the production of bicycle frames?

- Bicycle frames can be produced using steel strips, which are frequently utilized in this manufacturing process due to their strength, durability, and affordability. By shaping and welding steel strips, it becomes possible to construct the primary structure of the frame, establishing a sturdy and inflexible foundation. The employment of steel strips enables the attainment of various shapes and sizes, facilitating design flexibility and customization. Furthermore, steel frames deliver an exceptional riding experience by absorbing vibrations and providing a smooth and comfortable journey. In summary, steel strips are a perfect selection for the production of bicycle frames as they encompass a blend of strength, durability, and adaptability.

- Q: What are the safety precautions for handling steel strips?

- When handling steel strips, it is important to take several safety precautions to minimize the risk of accidents or injuries. Here are some key safety measures to follow: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, gloves, and steel-toed boots, to protect yourself from potential hazards. 2. Proper Lifting Techniques: Use correct lifting techniques, such as bending at the knees and keeping your back straight, to avoid strains or injuries when lifting heavy steel strips. 3. Secure Storage: Store steel strips in a secure and organized manner, ensuring they are stacked properly and secured to prevent them from falling or causing tripping hazards. 4. Adequate Training: Ensure that all personnel involved in handling steel strips have received proper training on safe handling procedures, including lifting, stacking, and moving them. 5. Equipment Inspection: Regularly inspect all equipment, such as cranes, forklifts, or hoists, used for handling steel strips to ensure they are in good working condition and meet safety standards. 6. Clear Communication: Establish clear communication protocols between workers involved in handling steel strips to avoid misunderstandings or accidents. 7. Avoid Overloading: Do not exceed the load-bearing capacity of equipment or storage areas when handling steel strips to prevent structural failures or collapse. 8. Watch for Sharp Edges: Be cautious of sharp edges on steel strips, as they can cause cuts or puncture wounds. Use appropriate protective measures, such as wearing gloves or using edge protectors, to minimize the risk. 9. Slips and Falls: Ensure work areas are clean and free from spills or debris that could cause slips or falls. Use appropriate non-slip mats or flooring, especially in areas where steel strips are being handled. 10. Emergency Preparedness: Have a well-defined emergency plan in place that includes procedures for responding to accidents or injuries related to steel strip handling. By following these safety precautions, you can minimize the risk of accidents and injuries while handling steel strips, ensuring a safe working environment for all involved.

- Q: What are the different surface texturing techniques for steel strips?

- Some of the different surface texturing techniques for steel strips include shot blasting, pickling, acid etching, brushing, and embossing.

Send your message to us

Steel Coil In Slip Good Quality Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords