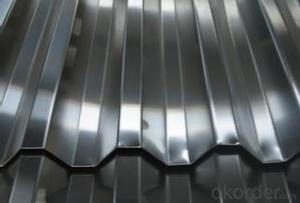

Good Quality of Corrugated Steel Coil from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

2.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

3.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

4. Hot-Dip Galvanized Steel Roof Description:

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

- Q: I have never owned a non-stainless steel chef's knife and have been looking at some to buy recently, but all of them have various degrees of wear and use. They say that the wear is normal for non-stainless steel knives, but how can I tell if it is too much wear, or if the blade is clean?

- Carbon steel chef's knives out perform stainless in every aspect except 1, care. You can't put them in a dishwasher. Wash, rinse and dry off. Do not keep them in a drawer filled with other kitchen stuff, rather, keep them in a cabinet or block. If it starts to rust you can use steel wool to clean them up, or fine grit sandpaper if you want to retain a fine finish. For your viewing pleasure, a chef's knife I forged from crane cable.

- Q: What are the different types of steel coil edge trimming methods?

- There are several different types of steel coil edge trimming methods, including shearing, slitting, and laser cutting. Shearing involves cutting the edges of the coil with a sharp blade, while slitting involves making multiple cuts to create narrower strips. Laser cutting uses a high-powered laser to precisely trim the edges of the coil. Each method has its own advantages and is used depending on the specific requirements of the steel coil application.

- Q: How are steel coils used in the manufacturing of agricultural structures?

- Steel coils are used in the manufacturing of agricultural structures as they provide the necessary strength and durability required for building structures such as barns, grain storage facilities, and equipment sheds. These coils are often used to fabricate beams, columns, and trusses, ensuring structural stability and resistance to harsh weather conditions. Additionally, steel coils are also used in the production of agricultural machinery and equipment, further enhancing the efficiency and reliability of farming operations.

- Q: How are steel coils used in the oil and gas industry?

- Steel coils are commonly used in the oil and gas industry for various purposes such as manufacturing pipelines, storage tanks, and offshore platforms. These coils are formed into cylindrical shapes and serve as the main structural component for these applications, providing strength, durability, and resistance to extreme conditions. Additionally, steel coils are used in the production of equipment like heat exchangers, compressors, and drilling machinery, which are essential for the extraction, processing, and transportation of oil and gas.

- Q: What are the common international standards for steel coils?

- The common international standards for steel coils include ASTM A653/A653M, EN 10142, JIS G3302, and ISO 3575. These standards provide specifications for the physical and mechanical properties of steel coils, such as the thickness, width, and coating requirements. They ensure consistent quality and compatibility in the global steel industry.

- Q: Could someone please explain what happens when steel is heat treated and why these happenings cause the steel to become harder? Please dig down into the micro details of the crystallites but in somewhat laymen's terms. Also describe the processes which achieve these results; if you have the time. Thanks for your time and effort.

- If you are speaking of a micro mini skirt, then i would think that the answer would be 1000 Hostess HoHo's would equal a macro skirt.

- Q: How are steel coils used in the manufacturing of body panels?

- Steel coils are used in the manufacturing of body panels by being processed and shaped into flat sheets or strips. These sheets or strips are then further formed, cut, and welded to create various body panels, such as doors, hoods, and fenders, which are essential components of vehicles.

- Q: What are the challenges in coil blanking for high-strength steel?

- Coil blanking for high-strength steel poses several challenges due to the unique properties of this material. One of the main challenges is the high tensile strength of the steel, which makes it more difficult to cut and blank compared to conventional steel grades. The high-strength steel is typically harder and less malleable, leading to increased tool wear and higher cutting forces. This requires the use of specialized cutting tools that are capable of withstanding these extreme conditions. Additionally, the increased cutting forces can lead to more vibration, which may affect the accuracy and quality of the blanks. Another challenge is the spring-back effect that high-strength steel exhibits after cutting. This means that the material tends to revert to its original shape, making it difficult to achieve precise dimensions and tolerances in the blanks. This issue requires careful consideration and adjustment of the cutting parameters to minimize the spring-back effect. Moreover, high-strength steel often has a higher carbon content, which can result in increased work hardening during the blanking process. Work hardening causes the material to become even harder and more brittle, making it more prone to cracks and fractures. To overcome this challenge, proper lubrication and cooling techniques are crucial to reduce heat buildup and minimize the risk of cracking. Furthermore, the increased strength of the steel may also affect the overall production efficiency. The higher cutting forces and tool wear mean that the cutting speeds may need to be reduced, leading to longer processing times. This can impact the productivity and throughput of the coil blanking process, requiring careful optimization and planning. In summary, the challenges in coil blanking for high-strength steel include increased cutting forces, tool wear, spring-back effect, work hardening, and reduced production efficiency. Overcoming these challenges requires specialized cutting tools, precise cutting parameters, proper lubrication and cooling techniques, and careful optimization of the production process.

- Q: What are the main factors that affect the paint adhesion on steel coils?

- The main factors that affect paint adhesion on steel coils are surface cleanliness, surface roughness, presence of contaminants, proper surface preparation, and the type of paint or coating being used.

- Q: How are steel coils used in the production of electrical resistors?

- Steel coils are used in the production of electrical resistors as the core material for winding wire around. The coils provide a stable structure, allowing the wire to be tightly wound and creating the necessary resistance for regulating electric current flow.

Send your message to us

Good Quality of Corrugated Steel Coil from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords