All Categories

- - Steel Wire Rod

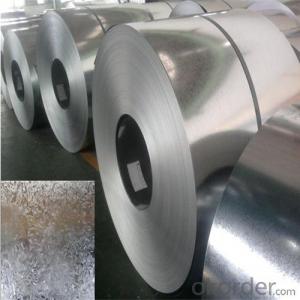

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can stainless steel coils be used in power generation applications?

Yes, stainless steel coils can be used in power generation applications. Stainless steel is known for its excellent corrosion resistance, high heat resistance, and strength, making it suitable for various power generation systems such as steam turbines, nuclear power plants, and renewable energy sources. Stainless steel coils help in maintaining efficient heat transfer and ensure long-term durability in these demanding environments.

What are the common applications of stainless steel coil?

Some common applications of stainless steel coil include manufacturing of kitchen appliances, automotive parts, construction materials, and industrial equipment. Stainless steel coil is also used in the production of pipes, tubing, and various types of fasteners due to its corrosion resistance and durability.

Can stainless steel coil be used in the textile manufacturing?

Yes, stainless steel coil can be used in textile manufacturing. It is commonly used as a component in various textile machinery, such as spinning frames, looms, and knitting machines. Stainless steel coils are preferred due to their durability, resistance to corrosion, and ability to withstand high temperatures.

What are the different types of surface finishes for stainless steel coils?

There are several types of surface finishes for stainless steel coils, including:

1. No.1 Finish: This is a hot-rolled, annealed, and descaled finish that has a rough, dull appearance.

2. No.2D Finish: Also known as a cold-rolled, annealed, and pickled finish, it has a smooth, semi-reflective surface.

3. No.2B Finish: Similar to No.2D, but with a brighter and more reflective surface.

4. No.3 Finish: A semi-polished finish achieved by using a 120-150 grit abrasive.

5. No.4 Finish: A brushed finish with a satin-like appearance obtained by using a 150-180 grit abrasive.

6. No.6 Finish: A highly reflective, mirror-like finish produced by using progressively finer abrasives.

7. No.7 Finish: A mirror-like finish achieved by buffing the surface with a polishing compound.

8. No.8 Finish: The highest-quality mirror-like finish achieved by using very fine abrasives and a final buffing process.

These different surface finishes offer varying levels of smoothness, reflectivity, and aesthetic appeal, allowing for a range of options to meet specific requirements in various industries.

Wholesale Stainless Steel Coil from supplier in Kiribati

We are a Stainless Steel Coil supplier serving the Kiribati, mainly engaged in the sale, quotation, and technical support services of various Stainless Steel Coil products in the Kiribati region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Stainless Steel Coil procurement services in the Kiribati. Not only do we have a wide range of Stainless Steel Coil products, but after years of market development in the Kiribati, we can also provide valuable experience for your projects.