All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

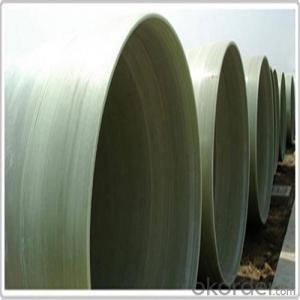

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

Can fiberglass be used in automotive applications?

Yes, fiberglass can be used in automotive applications. It is commonly used for various parts of a vehicle such as body panels, hoods, fenders, and interior components. Fiberglass is valued for its lightweight, high strength, corrosion resistance, and flexibility, making it an ideal material for improving fuel efficiency and performance in automobiles.

What are the different types of fiberglass surface coatings?

There are several different types of fiberglass surface coatings, including gelcoat, epoxy, polyurethane, and acrylic. Each coating offers unique benefits and properties, such as durability, UV resistance, chemical resistance, and ease of application. The choice of coating depends on the specific application and desired outcome.

How do you calculate the amount of fiberglass material required for a project?

To calculate the amount of fiberglass material required for a project, you need to determine the surface area that needs to be covered with fiberglass. Once you have the surface area measurement, you can consult the product specifications or supplier guidelines to determine the coverage rate of the fiberglass material. Multiply the surface area by the coverage rate to calculate the amount of fiberglass material required for your project.

How is fiberglass used in boat building?

Fiberglass is commonly used in boat building as it provides strength, durability, and resistance to water damage. It is used to create the hull, deck, and other structural components of the boat. The fiberglass material is layered with resin and then molded into the desired shape, resulting in a lightweight yet sturdy boat structure. Additionally, fiberglass allows for flexibility in design and can be easily repaired if damaged.

How does fiberglass supply handle extreme temperatures?

Fiberglass supply is highly resistant to extreme temperatures due to its excellent thermal insulation properties. It can withstand both high and low temperatures without cracking, warping, or losing its structural integrity. This makes fiberglass supply a reliable choice for various applications, including insulation, construction, and automotive industries.

Wholesale Fiberglass Supply from supplier in Kiribati

Whether you require fiberglass materials for construction, industrial applications, or any other project in Kiribati, we have you covered. Our sales team is highly knowledgeable and can assist you in selecting the right products based on your specific requirements.

We also provide quick and accurate quotes, ensuring transparency and competitive pricing. Our technical support team is available to answer any queries you may have and provide guidance on product installation and usage.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, ensuring a reliable and consistent supply of fiberglass materials. Our strong partnerships with global suppliers enable us to offer a wide range of high-quality products at competitive prices.

We understand the unique challenges and requirements of the Kiribati market. With our years of experience in the industry, we can provide valuable insights and recommendations for your projects. Whether you are working on a small-scale residential project or a large-scale industrial development, we have the expertise to assist you.

Our commitment to customer satisfaction means that we strive to provide efficient and hassle-free procurement services. We ensure timely delivery of products to your desired location in Kiribati, saving you time and effort.

Contact us today to discuss your fiberglass supply needs in Kiribati. Our dedicated team is ready to assist you and provide tailored solutions for your projects.

We also provide quick and accurate quotes, ensuring transparency and competitive pricing. Our technical support team is available to answer any queries you may have and provide guidance on product installation and usage.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, ensuring a reliable and consistent supply of fiberglass materials. Our strong partnerships with global suppliers enable us to offer a wide range of high-quality products at competitive prices.

We understand the unique challenges and requirements of the Kiribati market. With our years of experience in the industry, we can provide valuable insights and recommendations for your projects. Whether you are working on a small-scale residential project or a large-scale industrial development, we have the expertise to assist you.

Our commitment to customer satisfaction means that we strive to provide efficient and hassle-free procurement services. We ensure timely delivery of products to your desired location in Kiribati, saving you time and effort.

Contact us today to discuss your fiberglass supply needs in Kiribati. Our dedicated team is ready to assist you and provide tailored solutions for your projects.

Hot Search

- Fiberglass Chopped Strand in Jordan

- Fiberglass Mesh Cloth in Mongolia

- Composite Pipes in Zimbabwe

- FRP Pultrusion Profiles in Mauritania

- Fiberglass Mat Tissue in Hungary

- Fiberglass Fabrics in America

- Fiberglass Mesh in Australia

- Composite Tank in Benin

- Fiberglass Mesh tape in Kiribati

- Polymer in Guatemala