All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How are monolithic refractories used in the foundry industry?

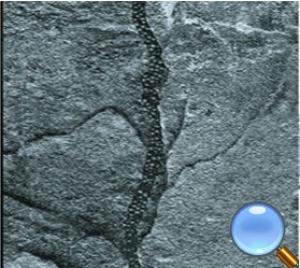

Monolithic refractories are extensively used in the foundry industry for lining various types of furnaces and kilns. They are applied as a single, cohesive mass, unlike traditional brick or tile refractories. Monolithic refractories offer several advantages, such as ease of installation, improved thermal insulation, and reduced maintenance. They are commonly used for lining the walls, roofs, and floors of furnaces, providing high-temperature resistance and protection against chemical attacks from molten metals and other harsh substances. Additionally, monolithic refractories can be easily shaped to fit complex geometries, allowing for more efficient heat transfer and better control of temperature distribution within the foundry equipment.

Can monolithic refractories be used for lining converters?

Yes, monolithic refractories can be used for lining converters. Monolithic refractories are known for their versatility and can be shaped and formed to fit various applications, including converter linings. They offer excellent thermal shock resistance, high temperature stability, and good resistance to chemical attacks, making them suitable for lining converters in industries such as steelmaking and non-ferrous metals.

How do monolithic refractories perform in terms of thermal shock resistance in high-temperature applications?

Monolithic refractories exhibit excellent thermal shock resistance in high-temperature applications. Their unique composition and structure allow them to withstand rapid temperature changes without cracking or deteriorating. This property ensures their reliability and longevity in demanding industrial settings where thermal cycling is common.

Can monolithic refractories be used for lining ladle slide gates and nozzles?

Yes, monolithic refractories can be used for lining ladle slide gates and nozzles. Monolithic refractories are versatile and can be shaped and molded to fit various applications, including ladle slide gates and nozzles. They offer excellent resistance to high temperatures and can withstand the harsh conditions of molten metal and slag. Monolithic refractories also provide good thermal shock resistance and have a longer service life, making them an ideal choice for lining ladle slide gates and nozzles.

Wholesale Monolithic Refractories from supplier in Kiribati

Whether you are in need of Monolithic Refractories for industrial furnaces, kilns, or any other high-temperature applications, we have the expertise to meet your requirements. Our team of professionals will work closely with you to understand your specific needs and provide tailored solutions that maximize efficiency and cost-effectiveness.

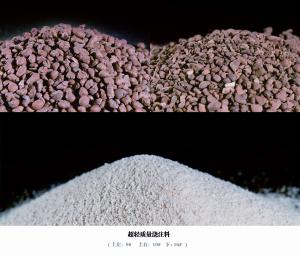

As a trusted supplier, we guarantee the highest quality products sourced from reputable manufacturers. Our comprehensive range of Monolithic Refractories includes castables, plastic refractories, ramming mass, gunning mix, and more. We ensure that our products are of the highest standard, offering superior thermal resistance, excellent mechanical strength, and long-lasting performance.

In addition to our product offerings, we provide comprehensive sales, quotation, and technical support services. Our team of experts is available to assist you throughout the entire procurement process, from product selection to after-sales support. We understand the importance of timely delivery and offer efficient logistics solutions to ensure your Monolithic Refractories reach you on time.

With our years of market experience in Kiribati, we have developed strong relationships with local suppliers and manufacturers. This allows us to provide you with valuable insights and expertise specific to the local market. We understand the unique challenges and requirements of working in Kiribati and can assist you in making informed decisions for your projects.

By choosing us as your supplier of Monolithic Refractories in Kiribati, you can be confident in receiving top-quality products, reliable services, and unmatched expertise. We are committed to meeting your needs and exceeding your expectations. Contact us today to discuss your requirements and discover how we can support your projects in Kiribati.

As a trusted supplier, we guarantee the highest quality products sourced from reputable manufacturers. Our comprehensive range of Monolithic Refractories includes castables, plastic refractories, ramming mass, gunning mix, and more. We ensure that our products are of the highest standard, offering superior thermal resistance, excellent mechanical strength, and long-lasting performance.

In addition to our product offerings, we provide comprehensive sales, quotation, and technical support services. Our team of experts is available to assist you throughout the entire procurement process, from product selection to after-sales support. We understand the importance of timely delivery and offer efficient logistics solutions to ensure your Monolithic Refractories reach you on time.

With our years of market experience in Kiribati, we have developed strong relationships with local suppliers and manufacturers. This allows us to provide you with valuable insights and expertise specific to the local market. We understand the unique challenges and requirements of working in Kiribati and can assist you in making informed decisions for your projects.

By choosing us as your supplier of Monolithic Refractories in Kiribati, you can be confident in receiving top-quality products, reliable services, and unmatched expertise. We are committed to meeting your needs and exceeding your expectations. Contact us today to discuss your requirements and discover how we can support your projects in Kiribati.

Hot Search

- Monolithic Refractories in Rwanda

- Ceramic Fiber Products in Lesotho

- Refractory Bricks in Paraguay

- Raw Materials For Refractory in Dominica

- Raw Materials For Refractory in Uruguay

- Raw Materials For Refractory in Iceland

- Refractory Bricks in Oman

- Refractory Bricks in Belarus

- Refractory Bricks in Ghana

- Monolithic Refractories in Spain