All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

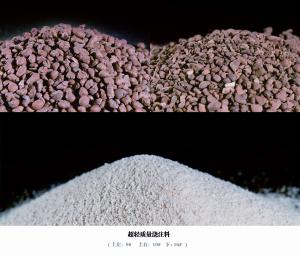

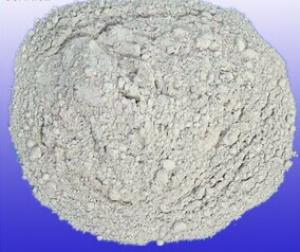

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can monolithic refractories be used for lining power plant boilers?

Yes, monolithic refractories can be used for lining power plant boilers. Monolithic refractories are often used in power plant boilers due to their excellent thermal shock resistance, high temperature stability, and ease of installation. They can withstand the extreme heat and thermal cycling conditions found in boiler environments, making them an ideal choice for lining power plant boilers.

How are monolithic refractories being used in the ceramic industry?

Monolithic refractories are extensively used in the ceramic industry for various applications. They are primarily used as linings in kilns, furnaces, and other high-temperature processing equipment. Monolithic refractories offer excellent thermal insulation and resistance to thermal shock, making them ideal for maintaining stable and efficient operating conditions in ceramic manufacturing. They also provide protection against chemical corrosion and mechanical wear, ensuring prolonged equipment lifespan. Additionally, monolithic refractories are used in the repair and maintenance of ceramic equipment, allowing for quick and convenient application. Overall, monolithic refractories play a crucial role in enhancing the performance, durability, and efficiency of ceramic industry processes.

How do monolithic refractories provide resistance to thermal shock in glass furnaces?

Monolithic refractories provide resistance to thermal shock in glass furnaces due to their unique properties and composition. These refractories are made from a single, continuous material without any joints or seams, which prevents the formation of cracks and weak points. Additionally, they have a high thermal conductivity, allowing them to evenly distribute heat and minimize temperature gradients. This, combined with their high thermal expansion coefficient, enables them to expand and contract with the extreme temperature changes experienced in glass furnaces, without fracturing or breaking. Overall, monolithic refractories provide a durable and reliable barrier against thermal shock, ensuring the efficient and continuous operation of glass furnaces.

How do monolithic refractories perform in corrosive gas environments?

Monolithic refractories generally perform well in corrosive gas environments as they are designed to withstand high temperatures and resist chemical attacks. They have excellent resistance to acidic gases and can provide a protective barrier against corrosive elements, thereby ensuring long-lasting performance and durability in such environments.

How do monolithic refractories handle alkaline attack?

Monolithic refractories are designed to withstand alkaline attack through several mechanisms. These refractories contain specialized additives and binders that provide resistance to alkaline corrosion. Additionally, they have a dense structure that limits the penetration of alkalis, preventing damage to the underlying material. The chemical composition of monolithic refractories is carefully chosen to resist alkaline attack, ensuring their long-term durability and performance in alkaline environments.

Wholesale Monolithic Refractories from supplier in Spain

We understand the importance of delivering high-quality products and services to our customers in Spain. That is why we only source Monolithic Refractories from trusted manufacturers, ensuring that you receive products that meet international standards and exceed your expectations.

In addition to our wide range of products, we also offer customized solutions to meet your specific project requirements. Our team of experts is available to provide technical support and guidance, helping you select the right Monolithic Refractories for your applications. We can also assist with product installation and maintenance, ensuring optimal performance and longevity.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of industry trends and advancements, ensuring that we can provide you with the latest and most innovative Monolithic Refractories solutions.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients by delivering exceptional service and quality products. We understand the importance of timeliness and reliability, and we work tirelessly to ensure that your orders are processed and delivered on time.

Choose us as your trusted partner for all your Monolithic Refractories needs in Spain. Contact us today to discuss your requirements and let us assist you in finding the perfect solution for your projects.

In addition to our wide range of products, we also offer customized solutions to meet your specific project requirements. Our team of experts is available to provide technical support and guidance, helping you select the right Monolithic Refractories for your applications. We can also assist with product installation and maintenance, ensuring optimal performance and longevity.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of industry trends and advancements, ensuring that we can provide you with the latest and most innovative Monolithic Refractories solutions.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients by delivering exceptional service and quality products. We understand the importance of timeliness and reliability, and we work tirelessly to ensure that your orders are processed and delivered on time.

Choose us as your trusted partner for all your Monolithic Refractories needs in Spain. Contact us today to discuss your requirements and let us assist you in finding the perfect solution for your projects.

Hot Search

- Monolithic Refractories in Malawi

- Ceramic Fiber Products in Dominica

- Refractory Bricks in Turkey

- Raw Materials For Refractory in Netherlands

- Monolithic Refractories in Vietnam

- Monolithic Refractories in Qatar

- Raw Materials For Refractory in Benin

- Monolithic Refractories in Mexico

- Monolithic Refractories in Samoa

- Ceramic Fiber Products in Japan