All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can ductile iron pipes be used for irrigation of agricultural fields?

Yes, ductile iron pipes can be used for irrigation of agricultural fields. Ductile iron pipes are known for their strength, durability, and corrosion resistance, making them suitable for various applications, including agricultural irrigation. Their ability to withstand high pressure and provide reliable water supply makes them an ideal choice for transporting water to agricultural fields efficiently.

What are the different options for pipe joint bolts with ductile iron pipe?

There are several options for pipe joint bolts with ductile iron pipe. Some commonly used options include mechanical joint bolts, flange bolts, and restrained joint bolts. Mechanical joint bolts are typically used for joining pipes with mechanical joint fittings, while flange bolts are used for connecting pipes with flange fittings. Restrained joint bolts are specifically designed to provide added strength and stability to the joint, preventing movement or separation of the pipes. Ultimately, the choice of joint bolt depends on the specific application and requirements of the project.

What is the difference between bell and spigot and flanged joint ductile iron pipes?

Bell and spigot and flanged joint ductile iron pipes are both commonly used for plumbing and water distribution systems, but they differ in their connection methods.

Bell and spigot joints consist of one pipe end with a circular flared or bell-shaped opening (bell) and another pipe end with a matching tapered or spigot-shaped projection (spigot). These two ends are joined by inserting the spigot end into the bell end and sealing it with a gasket or sealant. This type of joint provides a flexible and watertight connection, allowing for easy installation and maintenance.

On the other hand, flanged joint ductile iron pipes have flared and flat faces at each end. A set of bolts and nuts are used to connect the flanges of adjacent pipes, compressing a gasket between them to create a tight seal. Flanged joints offer a more rigid connection, making them suitable for higher pressure applications or situations where the pipes need to be disassembled frequently.

In summary, the main difference between bell and spigot and flanged joint ductile iron pipes lies in their connection methods. Bell and spigot joints offer flexibility and ease of installation, while flanged joints provide a more rigid and robust connection suitable for higher pressure systems or frequent disassembly.

Can ductile iron pipes be used for biogas plants?

Yes, ductile iron pipes can be used for biogas plants. Ductile iron is a strong and durable material that can withstand the corrosive nature of biogas. It is commonly used in various industries, including wastewater treatment and gas distribution, making it a suitable choice for biogas plants where the transportation of gases is involved.

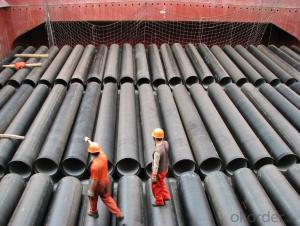

Wholesale Ductile Iron Pipes from supplier in Spain

With our strong network of suppliers and manufacturers, we can ensure that you receive high-quality Ductile Iron Pipes that meet all necessary standards and specifications. We work closely with our partners to ensure timely delivery and competitive pricing for all your procurement needs.

Furthermore, our technical support team is available to provide guidance and assistance throughout the entire process, from product selection to installation. We understand that each project is unique, and our experts will work closely with you to find the best solution for your specific requirements.

At our company, customer satisfaction is our top priority. We strive to exceed your expectations by providing exceptional service and support. Whether you are a contractor, engineer, or distributor, we have the knowledge and resources to meet your needs.

Choose us as your trusted supplier of Ductile Iron Pipes in Spain, and experience the convenience and efficiency of our one-stop procurement services. Contact us today to learn more about how we can assist you with your Ductile Iron Pipes needs.

Furthermore, our technical support team is available to provide guidance and assistance throughout the entire process, from product selection to installation. We understand that each project is unique, and our experts will work closely with you to find the best solution for your specific requirements.

At our company, customer satisfaction is our top priority. We strive to exceed your expectations by providing exceptional service and support. Whether you are a contractor, engineer, or distributor, we have the knowledge and resources to meet your needs.

Choose us as your trusted supplier of Ductile Iron Pipes in Spain, and experience the convenience and efficiency of our one-stop procurement services. Contact us today to learn more about how we can assist you with your Ductile Iron Pipes needs.

Hot Search

- Ductile Iron Pipes in Finland

- Ductile Iron Pipe Fittings in Slovakia

- Ductile Iron Pipe Fittings in Dominica

- Ductile Iron Pipe Fittings in Kuwait

- Ductile Iron Pipes in Guinea

- Ductile Iron Pipes in Algeria

- Ductile Iron Pipes in Vietnam

- Ductile Iron Pipe Fittings in Mali

- Ductile Iron Pipe Fittings in Guatemala

- Ductile Iron Pipes in Samoa