All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

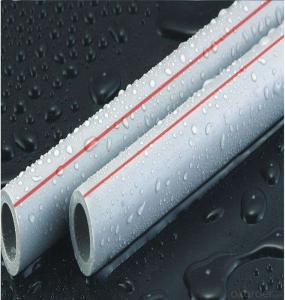

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can plastic tubes be used for industrial fluid transfer?

Yes, plastic tubes can be used for industrial fluid transfer. Plastic tubes are commonly used in various industries for transferring fluids such as water, chemicals, gases, and oils. They offer advantages such as flexibility, resistance to corrosion, lightweight, and cost-effectiveness. However, the specific type of plastic used for the tubes should be chosen based on the type of fluid being transferred and the operating conditions to ensure compatibility and safety.

Can plastic tubes be used for creating custom signage?

Yes, plastic tubes can be used for creating custom signage. They offer flexibility in design, easy customization, and durability. Plastic tubes can be shaped, bent, and cut into various sizes and forms to create unique and eye-catching signage. Additionally, they are weather-resistant, cost-effective, and can be illuminated for added visibility.

What are the different thicknesses available for plastic tubes?

The different thicknesses available for plastic tubes vary depending on the specific type and purpose of the tube. Generally, plastic tubes can range in thickness from thin-walled tubes that are just a few millimeters thick to thicker-walled tubes that can be several millimeters or even centimeters thick. The thickness required for a specific application will depend on factors such as the intended use, pressure requirements, and the material being transported or contained within the tube.

Can plastic tubes be used for cosmetic gift sets?

Yes, plastic tubes can be used for cosmetic gift sets. They provide a convenient and practical packaging option for various cosmetic products such as lotions, creams, and gels. Plastic tubes are lightweight, durable, and often come in various sizes and designs, making them suitable for creating attractive and appealing gift sets.

How do plastic tubes compare to nylon tubes?

Plastic tubes and nylon tubes have some key differences. Plastic tubes are usually made from various types of plastic materials, while nylon tubes are specifically made from nylon polymer. Nylon tubes tend to have higher strength, durability, and heat resistance compared to most plastic tubes. Nylon tubes are also often more flexible and resistant to chemicals and abrasion. However, plastic tubes can be more cost-effective and offer a wider range of options in terms of materials and sizes. Ultimately, the choice between plastic and nylon tubes depends on the specific requirements of the application.

Wholesale Plastic Tubes from supplier in Spain

Our team of experts is dedicated to understanding your specific needs and providing tailored solutions for your plastic tube requirements. Whether you are looking for tubes for industrial applications, construction projects, or packaging solutions, we have a wide range of options to meet your requirements.

We pride ourselves on delivering high-quality products that meet international standards and are manufactured using advanced technology and processes. Our plastic tubes are durable, reliable, and designed to withstand various environmental conditions.

In addition to our vast product range, we also offer sales, quoting, and technical support services to ensure a smooth and hassle-free procurement process. Our experienced team is always ready to assist you with any queries or concerns you may have.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and expertise to provide you with efficient procurement services. CNBM is known for its commitment to innovation, sustainability, and customer satisfaction, and we uphold these values in all aspects of our business.

Whether you are a small business or a large corporation, we are here to support your plastic tube needs in Spain. Contact us today to discuss your requirements and let us provide you with the best solutions for your projects.

We pride ourselves on delivering high-quality products that meet international standards and are manufactured using advanced technology and processes. Our plastic tubes are durable, reliable, and designed to withstand various environmental conditions.

In addition to our vast product range, we also offer sales, quoting, and technical support services to ensure a smooth and hassle-free procurement process. Our experienced team is always ready to assist you with any queries or concerns you may have.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and expertise to provide you with efficient procurement services. CNBM is known for its commitment to innovation, sustainability, and customer satisfaction, and we uphold these values in all aspects of our business.

Whether you are a small business or a large corporation, we are here to support your plastic tube needs in Spain. Contact us today to discuss your requirements and let us provide you with the best solutions for your projects.