All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

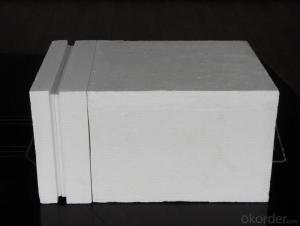

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the common refractory materials used for lining kilns?

The common refractory materials used for lining kilns are fire clay bricks, high alumina bricks, silica bricks, and magnesia bricks.

How do refractory materials contribute to the efficiency of smelting operations?

Refractory materials contribute to the efficiency of smelting operations by providing exceptional heat resistance and insulation, enabling them to withstand the extreme temperatures involved in the smelting process. They help maintain a stable and controlled environment inside the smelting furnace, preventing heat loss and optimizing energy usage. Moreover, refractory materials also protect the furnace lining from corrosion and erosion caused by the chemical reactions and molten metal, thereby extending the lifespan of the furnace and reducing downtime for repairs and maintenance.

How are refractory fibers used in insulation applications?

Refractory fibers are commonly used in insulation applications due to their exceptional high-temperature resistance and thermal stability. They are typically incorporated into insulation materials to provide insulation and prevent the transfer of heat, especially in environments where extreme temperatures are present. These fibers are woven or bonded together to create a dense and effective barrier that helps conserve energy and maintain a desired temperature within a space. Additionally, refractory fibers are lightweight, flexible, and easy to install, making them ideal for various insulation applications in industries such as aerospace, automotive, and manufacturing.

What are the challenges faced by refractory materials in the waste treatment industry?

Refractory materials in the waste treatment industry face several challenges, such as high temperatures, corrosive environments, and abrasive substances. These materials need to withstand extreme heat and chemical reactions while maintaining their physical integrity and durability. Additionally, they must resist erosion and wear caused by the abrasive nature of waste materials. The selection and design of refractory materials in this industry require careful consideration of these challenges to ensure long-lasting and effective waste treatment operations.

Wholesale Refractory Materials from supplier in Spain

Our team is ready to provide you with personalized sales and technical support, ensuring that you receive the best products and services for your specific needs. We understand the importance of timely and efficient procurement, and we strive to make the process as seamless as possible for our customers.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer competitive prices and superior quality products to our customers in Spain.

We take pride in our extensive selection of Refractory Materials, which includes bricks, castables, insulating materials, and refractory coatings. Our products are designed to withstand high temperatures and harsh conditions, making them ideal for industrial furnaces, kilns, and other applications.

At our company, we prioritize customer satisfaction and are dedicated to providing exceptional service. Our team of experts has a deep understanding of the Spanish market and can offer tailored solutions to meet your specific requirements.

Don't hesitate to contact us today to discuss your Refractory Materials needs in Spain. We look forward to assisting you and helping you achieve success in your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer competitive prices and superior quality products to our customers in Spain.

We take pride in our extensive selection of Refractory Materials, which includes bricks, castables, insulating materials, and refractory coatings. Our products are designed to withstand high temperatures and harsh conditions, making them ideal for industrial furnaces, kilns, and other applications.

At our company, we prioritize customer satisfaction and are dedicated to providing exceptional service. Our team of experts has a deep understanding of the Spanish market and can offer tailored solutions to meet your specific requirements.

Don't hesitate to contact us today to discuss your Refractory Materials needs in Spain. We look forward to assisting you and helping you achieve success in your projects.

Hot Search

- Monolithic Refractories in Portugal

- Ceramic Fiber Products in Uganda

- Refractory Bricks in Bulgaria

- Raw Materials For Refractory in Mali

- Refractory Bricks in Thailand

- Refractory Bricks in Estonia

- Monolithic Refractories in Spain

- Ceramic Fiber Products in Serbia

- Raw Materials For Refractory in Andorra

- Refractory Bricks in Nauru