Hot Rolled Steel With High Quality and Good Price Sheets From China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

DESCRIPTION FOR CARBON STEEL PLATE

Product | carbon steel plate price per ton |

Place of origin | Tianjin,China mainland |

MOQ | 25 tons |

Thickness | 1mm-200mm |

Width | 1000mm-3000mm |

Length | 1000mm-2000mm |

Application | widely |

Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

Tpye | Steel plate |

Surfacing | Coated |

Productive Technology | Hot Rolled & Cold Rolled |

Price | FOB USD 500-900 per ton |

Port | TIANJIN,SHANGHAI |

Payment Terms | L/C,T/T,Western Union,MoneyGram |

Product Ability | 1000 tons per month |

Delivery | 10 days after deposit or according to customers' quantity |

Packing | standard seaworthy export packing or as the request of customers |

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

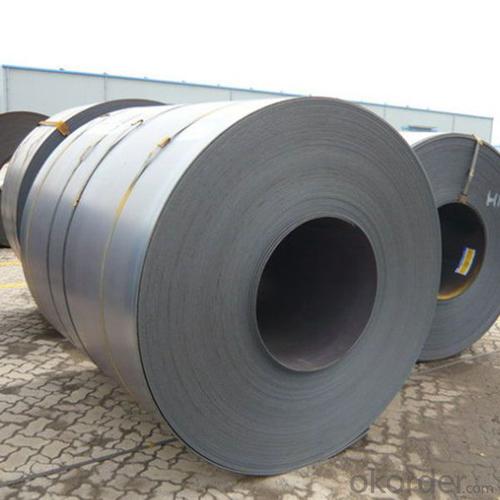

DETAILED PICTURES FOR STEEL COILS

EXPORT MARKET FOR STEEL COILS/SHEETS

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ:

Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

Q:How about the delivery time?

A:Within 15-30days after receiving the deposit or L/C at sight.

FAQ:

Q:You are Factory or Trading Company?

A:We are factory,our main products include Steel plate,Steel Bar,Steel coils.

Q:What’s the MOQ?

A:Generally,the trail order will be accepted.The MOQ can be confirmed according to the different products.For example,the MOQ of rebar will be 25-50MT,the galvanized steel pipe will be 10MT,the stainless steel pipe will 1-5MT.

- Q: What are the main characteristics of galvanized steel coils?

- The main characteristics of galvanized steel coils include their high corrosion resistance, durability, and ability to withstand extreme weather conditions. They are also known for their excellent formability, making them suitable for various applications in construction, automotive, and manufacturing industries. Additionally, galvanized steel coils have a smooth and shiny appearance due to the zinc coating, which provides aesthetic appeal along with enhanced protection against rust and other damages.

- Q: What is the process of slitting steel coils into narrower strips?

- The process of slitting steel coils into narrower strips involves unwinding the steel coil, passing it through a set of rotating circular blades called slitters, and then rewinding the resulting narrower strips onto separate spools.

- Q: What are the different coil leveling machine configurations used for steel coils?

- Steel coils can be processed using various coil leveling machine configurations, each designed to meet specific requirements. One commonly used configuration is the four-high leveling machine, consisting of a stack of four leveling rolls. These rolls apply pressure to flatten and level the steel coil. This configuration is ideal for thicker and heavier coils, as it offers greater pressure and control. Another option is the six-high leveling machine, which comprises two stacks of three leveling rolls each. The steel coil passes through the first stack for initial leveling and then through the second stack for further refinement. This configuration is suitable for thinner coils, allowing for a more precise and gentle leveling process. Additionally, combination leveling machines are available, integrating leveling with other processes like slitting or shearing. These machines provide a comprehensive solution for steel coil processing, particularly in applications requiring multiple steps to achieve the desired final product. Choosing the right coil leveling machine configuration depends on factors such as coil thickness, weight, desired precision, and efficiency. Manufacturers and processors must carefully assess their specific needs to select the appropriate configuration, ensuring optimal results in the steel coil leveling process.

- Q: How are steel coils packaged for transportation?

- Steel coils are typically packaged for transportation using a variety of methods to ensure their safe and secure delivery. The packaging process involves several steps to protect the coils from damage during transit and to facilitate their handling and loading onto trucks, ships, or trains. Firstly, steel coils are tightly wound and bound using steel straps or bands to keep them compact and prevent unwinding. These straps are usually made of high-strength steel and are securely fastened around the circumference of the coil at regular intervals. This helps to maintain the coil's shape and prevent any movement during transportation. Next, the coils are often placed on wooden or steel pallets to provide a stable base and facilitate handling with forklifts or cranes. The pallets are usually sized to fit the dimensions of the coils and are designed to withstand the weight and stress of the loaded coils. To provide additional protection, steel coils are often covered with a layer of protective material such as plastic or paper to shield them from moisture, dust, and other potential contaminants. This wrapping also helps to prevent scratching or damage to the outer surface of the coils. Furthermore, to secure the coils and prevent shifting during transit, they are often placed within a steel or wooden crate. These crates provide an extra layer of protection and stability, particularly for larger coils or when multiple coils are being transported together. Finally, once the coils are properly packaged, they are typically loaded onto flatbed trucks, shipping containers, or railway cars for transportation. During loading, proper care is taken to ensure that the coils are positioned securely and that weight distribution is balanced to prevent any potential damage or accidents during transit. In summary, steel coils are packaged for transportation by tightly binding them with steel straps, placing them on pallets, covering them with protective material, and, if necessary, enclosing them within crates. This packaging process helps to safeguard the coils and ensure their safe and efficient transportation to their destination.

- Q: How do steel coils compare to other types of metal coils?

- Steel coils are highly regarded for their exceptional strength and durability, making them superior to other types of metal coils. Steel is known for its high tensile strength, allowing it to withstand heavy loads and resist deformation. This makes steel coils ideal for applications that require a high level of structural integrity, such as in the construction and automotive industries. In addition to their strength, steel coils also offer excellent corrosion resistance. Various protective layers, such as zinc or paint, can be applied to steel to prevent rusting and ensure longevity. This makes steel coils suitable for outdoor and marine environments where exposure to moisture and harsh weather conditions is common. Furthermore, steel coils have a diverse range of mechanical properties that can be customized through different manufacturing processes. This allows for the production of steel coils with specific characteristics, including high ductility, heat resistance, or electrical conductivity, to meet the requirements of various industries. When compared to other metal coils, such as aluminum or copper, steel coils often have a lower cost. Steel is one of the most economical metals available, and its abundance in nature contributes to its affordability. This makes steel coils a cost-effective choice for many applications, especially when large quantities are required. Overall, steel coils are distinguished by their exceptional strength, durability, corrosion resistance, versatility, and affordability. These qualities make steel coils the preferred choice for a wide range of industries, including construction, manufacturing, transportation, and energy.

- Q: What is the average amount carbon emissions of steel per pound produced?

- Carbon okorder /... - Similar pages - Life-cycle energy and emissions of marine energy devices | Carbon ...Carbon dioxide emissions per unit mass of steel: 1.75 tCO2/tonne steel ; Total mass of steel in device: 665 tonnes ; Carbon dioxide emissions due to .

- Q: How are steel coils used in the production of wind turbine components?

- Wind turbine components rely heavily on steel coils for their production. These coils, typically crafted from high-strength steel, possess remarkable durability and resilience against harsh weather conditions. The tower, which serves as the wind turbine's main support structure, heavily relies on steel coils. These coils are used to construct the tower sections, which are then assembled to create a sturdy and tall structure capable of withstanding the weight of the nacelle and rotor blades. Steel coils also find essential application in the manufacturing of the rotor blades. Responsible for capturing wind energy and converting it into rotational motion, the rotor blades require a strong internal structure called the spar, which is constructed using steel coils. These coils are shaped and formed to achieve the desired blade shape, with composite materials added to enhance aerodynamic properties. Moreover, steel coils are utilized in the production of other wind turbine components like the hub and the nacelle. The hub, located at the center of the rotor, demands a robust steel structure to endure the immense forces generated by the rotating blades. The nacelle, which houses crucial turbine components such as the generator, also incorporates steel coils in its construction to ensure stability and protection. To summarize, steel coils play a vital role in the production of wind turbine components. From the tower to the rotor blades, hub, and nacelle, these coils provide the necessary strength, durability, and stability required to withstand the demanding conditions of wind energy production. Without them, the construction and operation of wind turbines would be impossible, as they serve as the backbone of these renewable energy systems.

- Q: Why is steel a stiff material?I'm doing a project on the use of steel in the construction of skyscrapers - and obviously, for the inner steel skeleton of a skyscraper the steel support beams and girders will have to be stiff so that they don't fall apart or the building doesn't shake due to wind or other natural forces.But in my research I've found that steel (mild steel to be more exact) is ductile and malleable, meaning it can be shaped fairly easily. However, how can steel ALSO be stiff - the definition of stiffness is the tendency to withstand bending and stretching - so my question is. How can this material be BOTH ductile/malleable, AND stiff? and why? :)Thank you in advance if anyone takes the time to answer this, would be appreciated - I'll give you 10 points straight away if the answers conclusive

- Steel is NOT stiff. In fact it is worldly accepted metals (steel is a metal) are not rigid in mechanical terms, and rigid means stiff. Steel easy to shape, but is strong and therefore hard to break. Thermosetting polymers (hard plastic) which is stiff, is in fact easy to break (weak) and also hard to reshape without changing its state (solid to liquid). Whoever told you steel is stiff is wrong and possible meant steel is strong, or you misheard/misunderstood.

- Q: I have the game of the year edition for fallout 3 but there's no mission or quest saying it's called broken steel so what is it actually called and where is it? Please describe the quest in case I mightve already done it without even knowing.

- Broken Steel fixes the original ending of the game so that you can continue past the end and continue exploring. The Broken Steel missions also take place after the original ending of the game. One way you can tell if Broken Steel is working though is if you are finding enemies added with Broken Steel (Super Mutant Overlords, Hellfire Enclave Troops, and so on), and if you can level up past level 20 and get new perks added between 20 and 30. You can even see all of these new perks any time you level up, so next time you level up, scroll down and see if there are new perks below the level 20 perks. If there are, then Broken Steel is working properly.

- Q: Cold rolled steel coil steel, what is the difference?

- Cold: hot rolled steel coil as raw material by pickling descaling after cold rolling, the finished rolling hard volumes, due to continuous deformation caused by cold hardening the volume rolling hard strength, hardness, toughness index rise decline, so the stamping performance will deteriorate, only for a simple deformation of parts. Rolled hard rolls can be used as raw material for hot galvanizing plants. Because the hot galvanizing units are equipped with annealing lines, the steel coils are rolled continuously at room temperature. Its strength is very high, but toughness, weldability is slightly worse, bright surface, not easy to corrosion, in order to prevent rust, the factory surface is coated with a protective layer of oil (hot rolling did not). Because of the complexity of the process, the price is higher.

Send your message to us

Hot Rolled Steel With High Quality and Good Price Sheets From China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords