Hot and Cold Rolled Steel Strip Coils with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Steel Strip Coils:

Steel strips is one of our main products that is widely used in making band saw blade & other blades to cut paper, weed, etc.

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

Specifications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil, kitchen ware

3:Architectural purpose, Milk & Food processing facilities

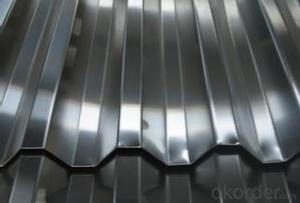

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: Can steel strips be used for making coins?

- No, steel strips are typically not used for making coins. Coins are usually made from metals such as copper, nickel, or zinc alloys for their durability and value.

- Q: How are steel strips hardened and tempered?

- Through a specific heat treatment process, steel strips can be hardened and tempered. Initially, the steel strips are subjected to high temperatures, referred to as the austenitizing temperature. This particular temperature facilitates the transformation of the steel into austenite, which possesses a face-centered cubic crystal structure. Once the austenitizing temperature is reached, the steel strips undergo rapid cooling through a process known as quenching. Quenching entails immersing the steel strips in a medium like oil, water, or polymer, causing the austenite to convert into a hard and brittle phase called martensite. This swift cooling ensures the steel strips attain maximum hardness. Nevertheless, martensite is exceedingly brittle and lacks toughness. To enhance toughness and diminish brittleness, the steel strips undergo tempering. During tempering, the steel strips are reheated to a lower temperature, typically ranging between 300-700 degrees Celsius. This reheating enables the reduction of excess hardness in the martensite, while simultaneously increasing the strength and toughness of the steel. The specific temperature and duration of the tempering process vary based on the desired mechanical properties of the steel strips. Higher tempering temperatures yield lower hardness but enhanced toughness, whereas lower temperatures result in higher hardness but diminished toughness. Ultimately, the combination of hardening and tempering enables steel strips to achieve a harmonious balance between hardness and toughness, rendering them suitable for diverse applications such as tool manufacturing, spring production, and structural components.

- Q: What are the different methods for etching steel strips?

- There are several methods for etching steel strips, including chemical etching, electrochemical etching, laser etching, and mechanical etching. Each method involves different techniques and processes to selectively remove material from the steel surface and create desired patterns or designs.

- Q: What are the different lengths available for steel strips?

- Steel strips are available in a variety of lengths to suit different applications and requirements. The lengths of steel strips can range from a few inches to several feet, depending on the intended use and the industry. Common lengths for steel strips can be found in standard sizes such as 12 inches, 24 inches, 36 inches, and so on. However, custom lengths can also be obtained by cutting longer strips to the desired size. Additionally, steel strips can be supplied in rolls or coils, which can have varying lengths depending on the thickness and width of the strip. Ultimately, the length of steel strips is determined by factors such as the specific industry, the intended use, and the customer's specifications.

- Q: Can steel strips be used in architectural applications?

- Yes, steel strips can definitely be used in architectural applications. Steel is a versatile and durable material that can be shaped into various forms, including strips, making it suitable for a wide range of architectural uses. Steel strips can be used for cladding, roofing, and siding applications, providing structural support while also enhancing the aesthetic appeal of a building. Additionally, steel strips are often used for decorative purposes, such as creating feature walls or accents, due to their sleek and modern appearance. Overall, steel strips offer architects and designers a flexible and reliable option for incorporating metal elements into their architectural projects.

- Q: How are steel strips used in the production of metal grating?

- Steel strips are an essential component in the production of metal grating. These strips are usually made from high-quality steel and are used to create the framework and support structure of the grating. Firstly, steel strips are cut into precise lengths and widths according to the desired dimensions of the metal grating. These strips are then welded or interlocked together to form a grid-like pattern, creating the overall structure of the grating. The welding process ensures that the strips are securely joined together, providing strength and durability to the final product. Moreover, steel strips can also be used to reinforce the edges of the metal grating. This reinforcement prevents the grating from bending or warping under heavy loads, ensuring its stability and structural integrity. The strips are often welded along the edges or can be attached with bolts or clips to further strengthen the grating. Additionally, steel strips can serve as the bearing bars or load-bearing components of the metal grating. These bars are responsible for carrying the weight and distributing it evenly across the grating surface. The strips are carefully spaced and aligned to provide proper support and prevent any sagging or deformation. Furthermore, steel strips can also be used to create serrated or anti-slip surfaces on the metal grating. These strips are usually attached to the top surface of the grating to enhance its grip and prevent accidents caused by slipping. The serrations or raised patterns on the steel strips provide additional traction, making the grating suitable for applications where slip resistance is crucial, such as industrial platforms or walkways. In summary, steel strips play a crucial role in the production of metal grating. They are used to create the framework, reinforce the edges, serve as load-bearing components, and provide slip resistance. These strips contribute to the overall strength, durability, and safety of the metal grating, making it suitable for a wide range of applications in various industries.

- Q: What is the tensile strength of galvanized steel strips?

- The tensile strength of galvanized steel strips can vary depending on various factors such as the grade and thickness of the steel, the galvanization process, and any additional treatments applied. Generally, galvanized steel strips have a tensile strength ranging from around 300 to 600 megapascals (MPa). However, it is important to note that specific tensile strength values may differ across different manufacturers and specific product specifications. Therefore, it is recommended to consult the manufacturer's technical data or specifications sheet for accurate and up-to-date information on the tensile strength of galvanized steel strips.

- Q: What are the different hardness options for steel strips?

- The different hardness options for steel strips typically range from soft to hard, with common options including annealed (soft), quarter hard, half hard, three-quarter hard, and full hard. These hardness options are achieved through various heat treatment processes, such as annealing, tempering, or cold rolling, to improve the steel's strength, flexibility, and durability for specific applications.

- Q: How are steel strips leveled or straightened?

- Steel strips are typically leveled or straightened through a process called leveling or flattening. This involves passing the strips through a series of rolls that apply pressure and tension to remove any deformations and ensure their flatness.

- Q: What is the electrical resistivity of a steel strip?

- The electrical resistivity of a steel strip can vary depending on various factors such as the composition of the steel, its temperature, and any impurities present. However, on average, the electrical resistivity of steel is typically around 6.5 x 10^-7 ohm-meters. It is important to note that this value can differ slightly for different types of steel or specific alloys used in the strip. Additionally, the electrical resistivity can also change with temperature, where it generally increases as the temperature rises.

Send your message to us

Hot and Cold Rolled Steel Strip Coils with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords