Stainless Steel Sheet ASTM Standard 200,300,400 Series

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Stainless Steel Sheet Description

The surface brightness and flatness of no2B is better than no2D. then through a special

surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses.

2.Main Features of the Stainless Steel Sheet

• Decoration

• Daily Necessities

•,Medical Treatment

• Daily Necessities

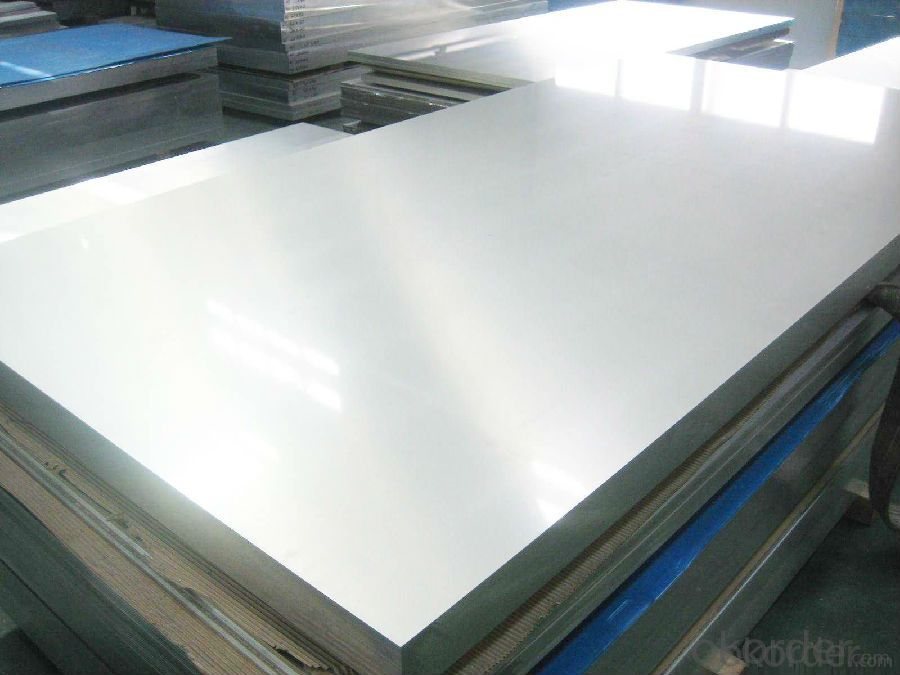

3. Stainless Steel Sheet Images

4. Stainless Steel Sheet Specification

Grade: | 200,300,400 Series Stainless Steel Sheet | Standard: | JIS,AISI,ASTM,GB,DIN,EN | Length: | 0-6000mm ,Or According to clients' requirement

|

Thickness: | 0.3mm-100mm | Width: | 10mm-2500mm | Place of Origin: | Shanxi China (Mainland) |

Brand Name: | CNBM | Model Number: | 200,300,400 Series,200,300,400 Series Stainless Steel Sheet

| Type: | Plate |

Application: | Decoration, Machinerhty,Lig Industry,Heavy Industry,Daily Necessities,Decoration,Kitchen,Building,Medical Treatment,Transport,Chemical

| Certification: | SGS,ISO,SGS | Technique: | Cold/hot rolled |

Surface Finish: | 2B,NO.1,NO.3,NO.4,HL,BA,8K,mirror,polished etc. | Exported Area: | USA,Europe,Asia,Middle East,Africa,South America | Packaging: | As Customers Requirement |

5.FAQ of Stainless Steel Sheet

①Who are you?

We are the manufacturer! We produce stainless steel products

with high quality & very competitive price!Please feel free to

contact us for more information!

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③How about your company?

A world class manufacturer & supplier of castings forging in Stainless Steel Sheet,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q: Can steel strips be used for making springs or clips?

- Yes, steel strips can be used for making springs or clips. Steel strips have excellent strength and flexibility properties, making them suitable for applications that require elasticity, such as springs and clips. They can be easily shaped, formed, and hardened to meet the specific requirements of the desired spring or clip design.

- Q: How are steel strips used in the production of conveyor belts?

- Steel strips are used in the production of conveyor belts to provide strength and durability. These strips are typically embedded within the belt to reinforce it and prevent stretching or tearing. They also help maintain the belt's shape and flexibility, allowing for smooth movement of materials along the conveyor system.

- Q: What are the different surface laminating options for steel strips?

- There are several surface laminating options for steel strips, including hot-dip galvanizing, electroplating, powder coating, and painting.

- Q: What are the mechanical properties of steel strips?

- The mechanical properties of steel strips include high tensile strength, excellent ductility, good toughness, and high resistance to corrosion and wear.

- Q: Can steel strips be used in the production of packaging materials?

- Indeed, the utilization of steel strips is feasible for the creation of packaging materials. Steel strips find extensive application in the production of diverse packaging materials, encompassing metal straps, bands, or seals. These packaging materials are extensively employed in industries such as shipping, transportation, and warehousing to effectively secure and bundle a wide array of goods and products. The outstanding strength and durability of steel strips render them highly suitable for demanding tasks. Moreover, their corrosion resistance and ability to withstand rough handling guarantee the utmost security and protection of packaged items throughout the transportation process.

- Q: How are steel strips annealed for improved properties?

- Steel strips are annealed for improved properties by heating them to a specific temperature and then slowly cooling them. This process helps to relieve internal stresses, improve ductility, and refine the grain structure of the steel, resulting in enhanced strength and toughness.

- Q: Can steel strips be used for making agricultural machinery?

- Indeed, agricultural machinery can indeed be crafted using steel strips. Given its robustness, longevity, and ability to resist deterioration, steel is a widely employed material in the production of agricultural machinery. Steel strips can be skillfully manipulated, fused, and molded into diverse components utilized in agricultural machinery, including plows, harrows, cultivators, seeders, and planters. Furthermore, for enhanced resistance against corrosion, steel strips can be galvanized, rendering them ideal for deployment in outdoor agricultural settings. On the whole, steel strips possess the essential attributes to endure the arduous conditions and rigorous utilization commonly linked with agricultural machinery.

- Q: What are the high speed steel strips and material specifications?

- (1) main usesUsed for stamping machine parts, metal products and manufacturing structural parts, etc..(2) the grade and chemical composition of the materialIn line with GB699 (high-quality carbon structural steel technical conditions), the brand is 15-70# steel provisions.

- Q: Can steel strips be used in the production of metal fences?

- Yes, steel strips can be used in the production of metal fences. Steel strips are commonly used as a material for fencing due to their strength, durability, and resistance to corrosion. They can be easily shaped and welded to create various fence designs while providing the necessary security and stability.

- Q: What are the common applications of steel strips?

- Steel strips have various common applications across industries. They are extensively used in manufacturing automotive parts, such as body panels, brackets, and reinforcements. Steel strips also find their use in the construction sector for producing roofing, cladding, and framing materials. Additionally, they are utilized in the production of electrical appliances, household goods, and various industrial machinery components. The versatility, durability, and strength of steel strips make them a preferred choice for a wide range of applications.

Send your message to us

Stainless Steel Sheet ASTM Standard 200,300,400 Series

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords