ASTM Standard 200,300,400 Series Stainless Steel Sheet/Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

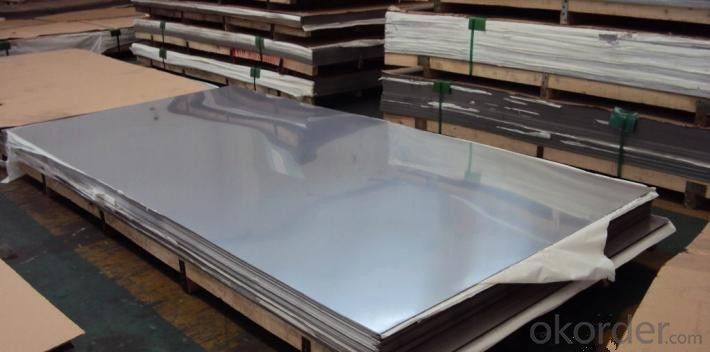

ASTM Standard 200,300,400 stainless steel sheet /Plate

1.Product introduction

We are the manufacturer! We produce stainless steel products with high quality & very competitive price!Please feel free to contact us for more information! | |

Product Name | ASTM Standard 200,300,400 Series Stainless Steel Sheet/Plate |

Standard | JIS AISI ASTM GB DIN |

Grade | 200/300/400 Series |

Thickness | 0.2mm-100mm |

Width | 100mm-2000mm |

Length | According to clients’ requirement |

Surface Finish | 2B ,BA ,8K ,NO4,NO2, NO1 ,Hair line ,EMBOSSED... |

Technique | Cold rolled ,Hot rolled |

Package | Seaworthy packing or as the consumers’ demand |

Application | Be used in manufacture of medical equipment, auto parts, heat-resistant kitchen utensils, electrical accessories , construction decoration ,etc |

Trade Term | FOB CIF |

Payment | T/T , L/C |

LoadingPort | Shanghai |

Delivery Time | 3-7days,mainly in accordance with the quantity |

Report | Material report ,Mechanical performance report |

Certification | ISO9001 |

2.Surface finishes and characteristic

Surface finish | Characteristics and application |

NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

NO.1 |

The surface is finished by heat treatment and pickling or processes corresponding thereto after hot rolling.

|

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Know more about trade...

Payment term: 1. 30% T/T in advance, and the balance against B/L copy

2. 100% irrevocable LC at sight.

Shipment date: Within 15-20 days after advance payment or receipt of LC

Trade term: 1. FOB Shanghai port, China.

2. CIF Discharging port

Guarantee& Service: Mill Test Certificate is supplied with shipment, and Third Part Inspection is acceptable.

Packing: standard export packing (plastic package to prevent water or plywood case to strengthen package)

- Q: How do you measure the hardness of a stainless steel bar?

- The hardness of a stainless steel bar can be measured using various methods, with the most common being the Rockwell hardness test. This test involves applying a specific amount of pressure to the surface of the bar using a diamond or a steel ball indenter, and then measuring the depth or the area of the resulting indentation. The hardness value is determined based on the depth or area measurement, which indicates the resistance of the stainless steel to penetration or deformation.

- Q: Are stainless steel bars suitable for architectural applications?

- Yes, stainless steel bars are highly suitable for architectural applications. They offer excellent corrosion resistance, durability, and a sleek aesthetic appearance, making them a popular choice for a wide range of architectural designs, including buildings, bridges, and decorative elements. Stainless steel bars also have high strength-to-weight ratio, allowing for versatility in design while maintaining structural integrity. Overall, stainless steel bars provide both functional and aesthetic benefits, making them a preferred material in architectural applications.

- Q: Are stainless steel bars suitable for the production of heat sinks?

- Yes, stainless steel bars are suitable for the production of heat sinks. Stainless steel has excellent thermal conductivity, which allows it to efficiently transfer heat away from the source. Additionally, stainless steel bars offer good corrosion resistance and durability, making them a reliable choice for heat sink production.

- Q: Can stainless steel bars be used in tennis racket frames?

- Yes, stainless steel bars can be used in tennis racket frames. Stainless steel is a strong and durable material that can provide stability and support to the racket frame, making it suitable for use in tennis rackets.

- Q: What is the elongation of stainless steel bars?

- The elongation of stainless steel bars refers to the amount of deformation or stretch they can undergo before breaking. It is a measure of the ductility or flexibility of the material and is usually expressed as a percentage of the original length.

- Q: What are the different testing methods for stainless steel bars?

- Various testing methods are available to evaluate the quality and performance of stainless steel bars, ensuring they meet required specifications and standards. These methods play a crucial role in the assessment of the bars. The following are some common testing methods for stainless steel bars: 1. Visual Inspection: Initially, a basic visual examination is done to identify any visible defects like surface imperfections, cracks, or irregularities. 2. Dimensional Inspection: Stainless steel bars' dimensions are measured using various tools and gauges to ensure they meet size, diameter, and length requirements. 3. Chemical Composition Analysis: Determining the chemical composition is essential to ensure the appropriate elements are present in the correct proportions. Spectroscopy techniques, like optical emission spectroscopy (OES) or X-ray fluorescence (XRF) analysis, are typically used for this purpose. 4. Mechanical Testing: Mechanical properties such as tensile strength, yield strength, elongation, hardness, and impact resistance are crucial for stainless steel bars. Tension, compression, or hardness tests determine these properties. 5. Non-Destructive Testing (NDT): This group of testing methods evaluates the integrity and quality of stainless steel bars without causing damage. Techniques like ultrasonic testing (UT), magnetic particle testing (MPT), dye penetrant testing (DPT), and eddy current testing (ECT) are commonly employed for this purpose. 6. Corrosion Testing: Various tests are conducted to assess stainless steel's resistance to different corrosive environments, including salt spray testing, pitting corrosion tests, intergranular corrosion tests, and crevice corrosion tests. 7. Microstructural Analysis: The microstructure of stainless steel bars significantly affects their properties. Techniques like metallography, electron microscopy, and X-ray diffraction can be used to analyze the microstructure and identify any defects or abnormalities. It is important to note that the choice of testing method may vary depending on specific requirements and applications of the stainless steel bars. Manufacturers and quality control personnel often use a combination of these testing methods to ensure the bars' quality, reliability, and suitability for their intended use.

- Q: What are the safety precautions when working with stainless steel bars?

- To ensure a safe work environment when handling stainless steel bars, it is crucial to adhere to specific safety measures. Here are some key precautions to consider: 1. Personal Protective Equipment (PPE): To safeguard yourself from potential hazards, it is essential to wear suitable PPE such as safety glasses, gloves, and steel-toed boots. Cut-resistant gloves are advisable due to the sharp edges and splinters of stainless steel bars. 2. Handling and Lifting: Proper lifting techniques and equipment should be utilized when moving or lifting heavy stainless steel bars. Avoid overloading and, if necessary, employ mechanical lifting devices like cranes or forklifts to prevent strain or injuries. 3. Ventilation: Maintaining adequate ventilation in the working area is crucial to minimize the inhalation of fumes or gases emitted during welding or cutting processes. Proper ventilation preserves air quality and reduces respiratory issues. 4. Fire Prevention: Although stainless steel is non-combustible, sparks generated during cutting or welding operations can pose a fire hazard. Keep the work area free from flammable materials and have appropriate fire extinguishing equipment readily accessible. 5. Electrical Safety: If electrical tools or equipment are used when working with stainless steel bars, it is important to inspect and use them correctly. Avoid using damaged or faulty equipment and always disconnect power sources before making adjustments or repairs. 6. Tool Selection: It is vital to select appropriate tools for cutting or shaping stainless steel bars. Ensure that the tools are in good condition, properly sharpened, and suitable for the specific task at hand. Using the wrong tool can result in accidents or material damage. 7. Secure Work Area: To minimize the risk of accidents, trip hazards, and injuries, it is crucial to maintain a clean and organized work area. Remove any clutter, debris, or loose objects that may cause slips, falls, or other accidents. 8. Training and Knowledge: Adequate training and a thorough understanding of the specific risks associated with working with stainless steel bars are essential. Regular safety training and updates are imperative to maintain a safe working environment. By adhering to these safety precautions, the likelihood of accidents, injuries, or health hazards when working with stainless steel bars can be significantly reduced.

- Q: Can stainless steel bars be used in desalination plants?

- Yes, stainless steel bars can be used in desalination plants. Stainless steel is highly resistant to corrosion, making it an ideal material for use in such environments where high levels of saltwater are present. Its durability and strength make it suitable for various applications within desalination plants, such as structural support, piping, and equipment.

- Q: Can stainless steel bars be used in brewing and distilling equipment?

- Brewing and distilling equipment can indeed utilize stainless steel bars. These industries commonly opt for stainless steel due to its remarkable resistance to corrosion, durability, and hygienic properties. Various components of brewing and distilling equipment, like tanks, fermenters, piping, fittings, valves, and agitators, can be manufactured using stainless steel bars. The material's ability to resist corrosion ensures its ability to endure the harsh and corrosive conditions typically present in brewing and distilling processes, including exposure to acids, chemicals, and high temperatures. Moreover, stainless steel is effortless to clean and maintain, a crucial factor in guaranteeing the purity and quality of the final product. In summary, stainless steel bars are a dependable and widely embraced choice for brewing and distilling equipment.

- Q: Can stainless steel bars be used in aerospace components manufacturing?

- Stainless steel bars are indeed applicable for aerospace components manufacturing. Stainless steel possesses superior characteristics such as exceptional strength, resistance to corrosion and heat, all of which are highly sought-after in aerospace applications. It is widely utilized in the production of diverse aerospace components including engine parts, structural elements, fasteners, and landing gear. Stainless steel bars can be skillfully machined, welded, and shaped into various forms to precisely meet the specific demands of aerospace components. Furthermore, stainless steel's capability to endure extreme temperatures and adverse conditions renders it an apt material for aerospace applications where durability and dependability are of utmost importance.

Send your message to us

ASTM Standard 200,300,400 Series Stainless Steel Sheet/Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords