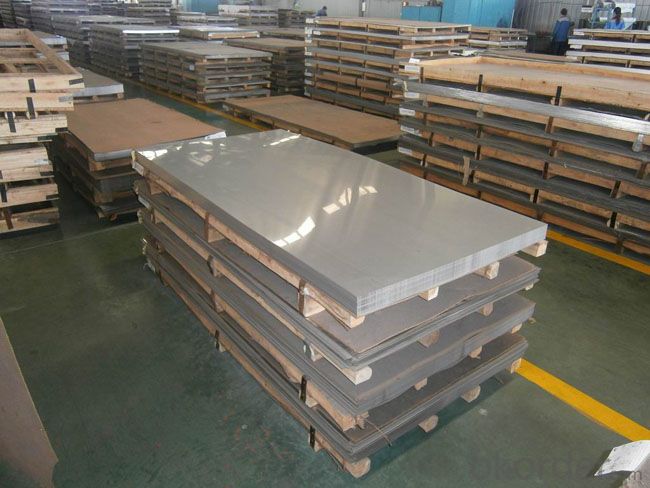

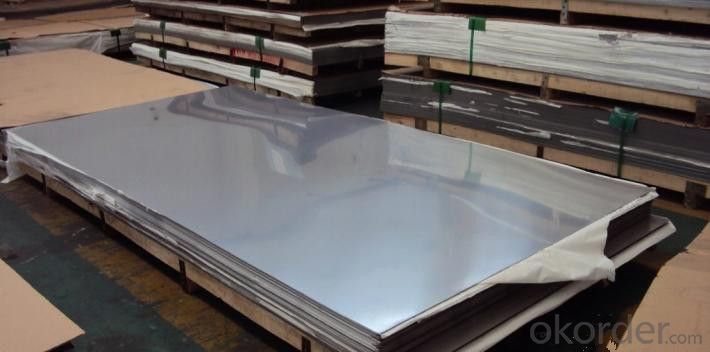

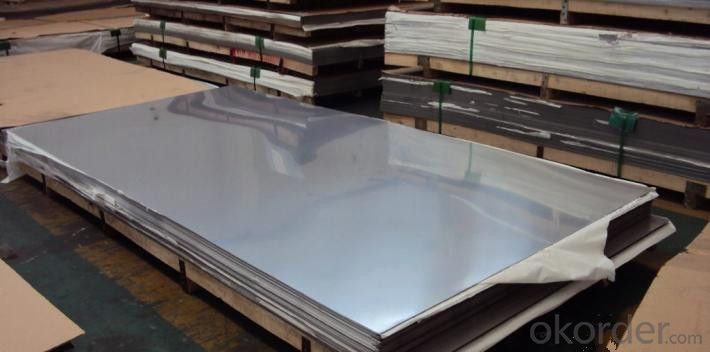

Stainless Steel Sheet 201/202/304/304L/316/316L/310/310s/430

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Sheet

Quick Details:

Specifications of Stainless Steel Sheets:

1. Material: 200series&300series&400series

2. Standard: JIS, AISI, ASTM, GB, DIN, EN

3. Thickness: 0.3-100mm or as customer’s requirement

4. Width: 1500-2200mm or as customer’s requirement

5. Length: 1000-6000mm or as customer’s requirement

6. Surface: 2B, BA, No.1, etc

7. Technical processing: Hot Rolled/Cold Rolled

8. Decorative:

Mirror, No.4, HL NSP, Bead Blast, Vibration,

HL Gold, Mirror Gold, Vibration Gold NSP,

No4 Copper NSP, Mirror Copper, Bead Copper,

HL Brass, Mirror Brass, Bead Brass,

HL Black, Mirror Black, Bead Black NSP,

HL Bronz, Mirror Bronze, Vibration Bronze,

Mirror Etched, HL Etched Copper, Mirror Black Etched, Mirror Etched Gold.

Features of 304 Stainless Steel Sheet/pipe/bar:

Accurate dimension

Minimum maintenance

Excellent service life

Non Corrosive

Heat Resistant

Know more about trade...

Payment term: 1. 30% T/T in advance, and the balance against B/L copy

2. 100% irrevocable LC at sight.

Shipment date: Within 15-20 days after advance payment or receipt of LC

Trade term: 1. FOB Shanghai port, China.

2. CIF Discharging port

Guarantee& Service: Mill Test Certificate is supplied with shipment, and Third Part Inspection is acceptable.

Packing: standard export packing (plastic package to prevent water or plywood case to strengthen package)

- Q: What are the different types of stainless steel bars used in agricultural equipment?

- Agricultural equipment commonly utilizes several types of stainless steel bars. These bars are selected based on their specific properties and suitability for various applications in the agricultural industry. 1. Austenitic stainless steel bars are renowned for their exceptional corrosion resistance and high ductility. They are commonly employed in agricultural equipment where exposure to moisture and corrosive elements is a concern. Ideal for applications such as tanks, silos, and irrigation systems. 2. Martensitic stainless steel bars are known for their high strength and hardness. They find extensive use in robust and durable components of agricultural equipment, including tillers, plows, and harvesting machinery. These bars provide excellent wear resistance and can withstand heavy-duty applications. 3. Ferritic stainless steel bars possess magnetic properties and resistance to corrosion and oxidation. They are often utilized in agricultural equipment that requires high-temperature resistance, such as exhaust systems, heaters, and drying equipment. Ferritic stainless steel bars are also recognized for their good formability and weldability. 4. Duplex stainless steel bars combine austenitic and ferritic properties, offering exceptional strength, corrosion resistance, and toughness. They are well-suited for demanding agricultural applications and find common use in equipment such as manure spreaders, balers, and feeders. 5. Precipitation-hardening stainless steel bars exhibit high strength and excellent corrosion resistance. They are frequently employed in agricultural equipment that requires outstanding performance under extreme conditions, such as sprayers, seeders, and irrigation pumps. These bars can endure high pressures and harsh environments. In conclusion, the different types of stainless steel bars used in agricultural equipment possess distinct properties and characteristics that cater to specific applications. The choice of stainless steel depends on factors such as corrosion resistance, strength, hardness, temperature resistance, and the specific requirements of the agricultural equipment.

- Q: Are stainless steel bars resistant to heat?

- Yes, stainless steel bars are highly resistant to heat. They have excellent heat resistance properties, allowing them to withstand high temperatures without losing their strength or structural integrity.

- Q: Are stainless steel bars suitable for heat recovery systems?

- Stainless steel bars are indeed appropriate for heat recovery systems due to their excellent resistance to corrosion. This characteristic proves crucial in high-temperature environments where exposure to various gases or liquids is common. Moreover, stainless steel boasts commendable thermal conductivity, ensuring efficient heat transfer throughout the system. Its strength and durability further establish it as a dependable choice for enduring the rigorous conditions of heat recovery systems. Furthermore, the malleability of stainless steel bars allows for easy fabrication into different shapes and sizes, providing the flexibility needed to design and construct heat recovery systems tailored to specific requirements. In conclusion, stainless steel bars are a widely preferred material in heat recovery systems due to their corrosion resistance, thermal conductivity, durability, and adaptability.

- Q: Are stainless steel bars suitable for oil and gas applications?

- Stainless steel bars prove to be suitable for oil and gas applications, undoubtedly. Owing to its remarkable resistance to corrosion, stainless steel emerges as an ideal choice in environments teeming with oil and gas. The material exhibits exceptional endurance against the harshest conditions and corrosive elements prevalent in these industries, encompassing exposure to chemicals, elevated temperatures, and immense pressure. The strength and durability offered by stainless steel bars further guarantee their long-lasting and dependable performance in oil and gas applications. Moreover, the non-magnetic nature of stainless steel assumes great significance in specific oil and gas processes that mandate the avoidance of magnetic interference. In conclusion, stainless steel bars reign supreme as the preferred material for oil and gas applications due to their corrosion resistance, strength, durability, and non-magnetic properties.

- Q: Can stainless steel bars be used in the food and beverage industry?

- Yes, stainless steel bars can be used in the food and beverage industry. Stainless steel is a popular choice for equipment and utensils in this industry due to its excellent corrosion resistance, durability, and hygienic properties. Stainless steel bars can be used for various purposes such as forming structures, creating shelving units, manufacturing food processing equipment, and constructing countertops and work surfaces. The high resistance to rust and staining makes stainless steel bars ideal for contact with food and beverages, as they do not contaminate or alter the taste or quality of the products. Additionally, stainless steel is easy to clean and maintain, which is crucial in an industry where cleanliness and sanitation are of utmost importance. Overall, stainless steel bars are widely accepted and used in the food and beverage industry for their reliability, safety, and suitability for food handling and processing.

- Q: Can stainless steel bars be used in the manufacturing of reactor vessels?

- Yes, stainless steel bars can be used in the manufacturing of reactor vessels. Stainless steel is a commonly used material in the construction of reactor vessels due to its excellent corrosion resistance, high strength, and durability. It can withstand high temperatures and is resistant to chemical reactions, making it suitable for containing and withstanding the harsh conditions within a reactor vessel.

- Q: Can stainless steel bars be used in hydraulic applications?

- Yes, stainless steel bars can be used in hydraulic applications. Stainless steel is known for its high strength, corrosion resistance, and durability, making it suitable for various industrial applications, including hydraulics. Stainless steel bars are often used in hydraulic systems where resistance to chemicals, moisture, and high temperatures is required. Additionally, stainless steel bars have good mechanical properties, such as high tensile strength and hardness, which make them capable of withstanding the high pressures and loads that hydraulic systems often experience. Overall, stainless steel bars are a reliable and efficient choice for hydraulic applications.

- Q: Are stainless steel bars resistant to erosion?

- Yes, stainless steel bars are highly resistant to erosion. Stainless steel is specifically designed to withstand corrosion and erosion due to its composition, which includes a significant amount of chromium. The addition of chromium creates a protective, passive oxide layer on the surface of the steel, which acts as a barrier against corrosive elements. This oxide layer prevents the steel from coming into direct contact with corrosive substances, such as water, chemicals, or atmospheric pollutants, thereby reducing the risk of erosion. Additionally, stainless steel bars can also be further enhanced with various alloys or coatings to enhance their resistance to specific corrosive environments. Overall, stainless steel bars are widely used in industries where erosion resistance is essential, such as marine, chemical, and construction industries.

- Q: How do stainless steel bars resist pitting and crevice corrosion?

- Stainless steel bars resist pitting and crevice corrosion due to their high content of chromium and other alloying elements. Chromium forms a protective oxide layer on the surface of the steel, known as the passive layer, which acts as a barrier against corrosion. This passive layer is self-healing, meaning that if it gets damaged or scratched, it can re-form and continue to protect the steel. Additionally, the alloying elements present in stainless steel enhance its resistance to both pitting and crevice corrosion, making it a durable and reliable material for various applications.

- Q: Can stainless steel bars be used in food processing plants?

- Stainless steel bars are indeed applicable for utilization in food processing plants. The utilization of stainless steel in the construction of equipment and fixtures in such plants is prevalent owing to its numerous desirable characteristics. The corrosion resistance of stainless steel is particularly significant in an environment where food products and cleaning agents coexist. Moreover, stainless steel is effortless to clean and maintain, thereby ensuring hygiene in food processing plants. Furthermore, stainless steel exhibits non-reactivity, thereby preventing any interaction with the food, thereby safeguarding its taste and quality. In conclusion, the durability, corrosion resistance, and hygienic properties of stainless steel bars render them an appropriate material for use in food processing plants.

Send your message to us

Stainless Steel Sheet 201/202/304/304L/316/316L/310/310s/430

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords