stainless steel round bar

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless Steel round Bar

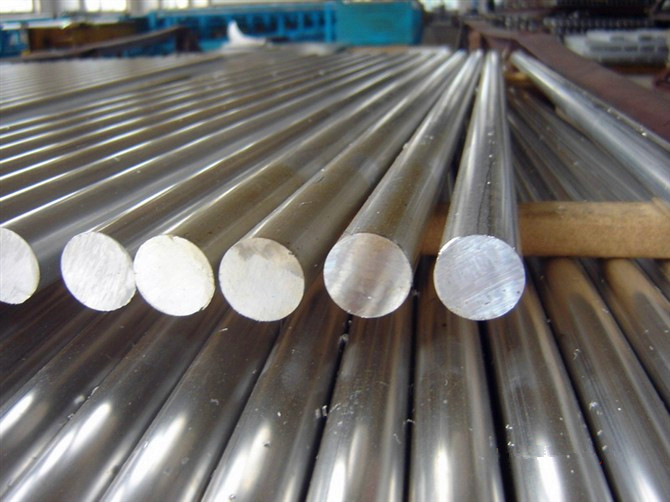

Specifications

stainless steel round bar1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

A series of pictures

- Q: Are stainless steel bars suitable for cleanroom applications?

- Stainless steel bars are indeed suitable for cleanroom applications. In cleanroom environments, stainless steel is highly preferred due to its remarkable cleanliness, durability, and resistance to corrosion. It possesses a non-porous and non-shedding nature, thereby preventing the release of particles or contaminants into the air. Furthermore, stainless steel bars are effortless to clean and maintain, making them the perfect fit for cleanroom applications where hygiene and cleanliness hold utmost importance. Moreover, stainless steel exhibits exceptional strength and stability, ensuring the bars can endure heavy loads and serve as a dependable support structure in cleanrooms. All in all, stainless steel bars offer a trustworthy and appropriate choice for cleanroom applications.

- Q: Are stainless steel bars suitable for aerospace engine components?

- Stainless steel bars are indeed appropriate for aerospace engine components. Their outstanding corrosion resistance, impressive strength, and commendable heat resistance properties have established them as a favored option for diverse aerospace uses. Within the aerospace sector, stainless steel bars are frequently utilized in engine components like shafts, turbine blades, and compressor discs. These crucial elements necessitate materials capable of enduring elevated temperatures, extreme pressure, and corrosive surroundings, all of which stainless steel can deliver. Moreover, stainless steel's capacity to sustain its mechanical properties across a wide range of temperatures guarantees its reliability and durability as a material for aerospace engine components.

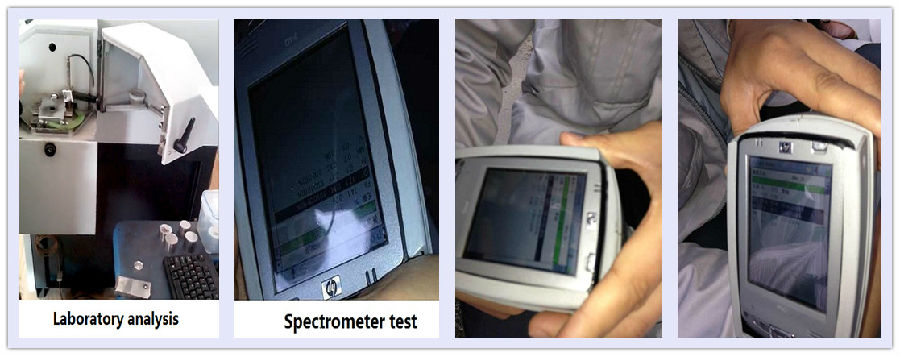

- Q: How are stainless steel bars tested for quality control?

- Stainless steel bars are thoroughly tested for quality control using various methods to ensure their durability, strength, and resistance to corrosion. One of the primary tests conducted on stainless steel bars is the chemical composition analysis. This involves examining the elemental composition of the steel to ensure it meets the specified requirements. This is crucial as even slight variations in the composition can significantly impact the quality and performance of the bars. Another important test is the mechanical properties analysis. This includes evaluating the tensile strength, yield strength, elongation, and impact resistance of the steel bars. These tests determine the ability of the bars to withstand external forces and stresses. To assess the resistance to corrosion, stainless steel bars undergo corrosion testing. This typically involves exposure to various corrosive environments, such as salt spray, to evaluate their performance over time. This test ensures that the bars can withstand harsh conditions without deteriorating or developing rust. Furthermore, dimensional inspection is carried out to verify that the bars meet the required size and shape specifications. This involves measuring the length, diameter, straightness, and surface finish of the bars. Any deviations from the specified dimensions are thoroughly examined and rectified to maintain high-quality standards. In addition to these tests, non-destructive testing methods are employed to detect any internal or surface defects. Techniques such as ultrasonic testing, magnetic particle inspection, and dye penetrant testing are used to identify cracks, voids, or other imperfections that may compromise the quality and integrity of the bars. All these tests are conducted in accordance with international standards and guidelines to ensure consistency and reliability in the quality control process. By subjecting stainless steel bars to comprehensive testing procedures, manufacturers can guarantee that the bars meet the desired quality standards and are suitable for various applications in industries such as construction, manufacturing, and infrastructure.

- Q: What is the thermal expansion coefficient of stainless steel bars?

- The thermal expansion coefficient of stainless steel bars varies depending on the specific grade of stainless steel. In general, stainless steel exhibits a lower thermal expansion coefficient compared to metals like aluminum or copper. The coefficient of thermal expansion for stainless steel falls within the range of 9 to 16 × 10^-6 per °C (or 9 to 16 μm/m·°C). It should be noted that the coefficients of different grades of stainless steel differ slightly due to variations in their chemical composition and microstructure. The precise thermal expansion coefficient of stainless steel bars used in production depends on the specific grade employed. Understanding the thermal expansion coefficient is crucial when considering the impact of temperature changes on stainless steel bars. As the temperature rises or falls, stainless steel bars will expand or contract accordingly. This information is vital for the design of structures, machinery, or components that may be exposed to varying temperatures. It ensures a proper fit and prevents potential issues arising from thermal expansion or contraction.

- Q: Are stainless steel bars suitable for machining?

- Yes, stainless steel bars are suitable for machining. Stainless steel is known for its excellent machinability, making it easy to cut, shape, and drill. It also offers high strength and durability, making it suitable for various machining applications in industries such as automotive, aerospace, and manufacturing.

- Q: Can stainless steel bars be used in automotive manufacturing?

- Yes, stainless steel bars can be used in automotive manufacturing. Stainless steel is a versatile and durable material that offers numerous benefits for automotive applications. It has excellent corrosion resistance, which is particularly important in the automotive industry where vehicles are exposed to various environmental conditions. Stainless steel bars are commonly used for manufacturing automotive components such as exhaust systems, suspension parts, and engine components. They provide strength, stability, and longevity to these parts, ensuring the safety and reliability of the vehicle. Additionally, stainless steel bars can be easily fabricated and welded, making them suitable for various automotive manufacturing processes. Overall, stainless steel bars are widely used in automotive manufacturing due to their exceptional properties and ability to meet the demanding requirements of the industry.

- Q: How do stainless steel bars compare to other metal bars?

- Stainless steel bars are highly regarded for their exceptional properties and characteristics, making them one of the most sought-after metal bars in various industries. In comparison to other metal bars, stainless steel bars offer several distinct advantages. Firstly, stainless steel bars are highly resistant to corrosion and rust, making them an ideal choice for applications that require durability and longevity. This corrosion resistance is attributed to the presence of chromium, which forms a protective oxide layer on the surface of the stainless steel, preventing it from being affected by external factors such as moisture, chemicals, or atmospheric conditions. In contrast, other metal bars, such as carbon steel or aluminum, are more prone to corrosion and require additional protective coatings or maintenance to prevent deterioration. Secondly, stainless steel bars possess excellent strength and toughness, allowing them to withstand heavy loads and high-pressure environments. This inherent strength makes stainless steel bars suitable for applications that require structural integrity or resistance to deformation. Compared to other metal bars, stainless steel has a higher strength-to-weight ratio, meaning it can provide the same strength with a lower weight, making it more cost-effective and efficient. Additionally, stainless steel bars exhibit superb heat resistance, maintaining their strength and structural integrity even at high temperatures. This property is crucial in industries such as aerospace, automotive, or manufacturing, where metal bars are subjected to extreme heat conditions. Other metals, such as aluminum or copper, may experience thermal expansion or deformation under high temperatures, making stainless steel bars a superior choice in such scenarios. Furthermore, stainless steel bars offer exceptional hygiene and cleanliness, making them widely used in industries like food processing, pharmaceuticals, and healthcare. The smooth and non-porous surface of stainless steel bars makes them easy to clean, resistant to bacterial growth, and capable of maintaining high sanitary standards. In contrast, other metals may have porous or rough surfaces that can trap bacteria or contaminants, compromising the hygiene and safety of the application. In conclusion, stainless steel bars surpass other metal bars in terms of corrosion resistance, strength, heat resistance, and hygiene. These qualities make stainless steel bars a versatile and reliable choice for a wide range of applications across various industries, ensuring long-lasting performance and cost-effectiveness.

- Q: Are stainless steel bars suitable for pharmaceutical packaging equipment?

- Yes, stainless steel bars are suitable for pharmaceutical packaging equipment. Stainless steel is known for its corrosion resistance, strength, and hygienic properties, making it an ideal material choice for equipment used in pharmaceutical packaging. It ensures that the packaging process remains sanitary, protects the integrity of the pharmaceutical products, and complies with the stringent standards and regulations of the industry.

- Q: What are stainless steel bars used for?

- Stainless steel bars possess durability, strength, and corrosion resistance properties that find extensive use in diverse industries. The construction industry frequently utilizes stainless steel bars to reinforce concrete structures like bridges, buildings, and highways, ensuring the longevity and structural integrity of these projects. In the manufacturing sector, stainless steel bars play a crucial role in producing machinery and equipment. These bars are machined, formed, or welded to create components that require high strength, heat resistance, chemical resistance, and wear resistance. Industries such as automotive, aerospace, and oil and gas heavily rely on stainless steel bars for manufacturing parts like shafts, valves, fasteners, and fittings. The food and beverage industry extensively utilizes stainless steel bars due to their non-reactive nature. This makes stainless steel an ideal material for food processing equipment, including conveyor systems, mixers, tanks, and storage containers. It ensures the safety and hygiene of food products by preventing contamination and facilitating easy cleaning. Furthermore, the marine industry heavily relies on stainless steel bars due to their excellent resistance to saltwater corrosion. These bars are commonly used in boat fittings, propeller shafts, and other components exposed to harsh marine environments. Additionally, stainless steel bars find application in architectural projects such as handrails, balustrades, and decorative elements. The aesthetic appeal, durability, and low maintenance requirements of stainless steel make it a popular choice for enhancing the appearance and functionality of buildings and public spaces. In conclusion, stainless steel bars serve diverse purposes across various industries. Their versatility, strength, and corrosion resistance make them indispensable in the construction, manufacturing, food processing, marine, and architectural sectors.

- Q: Are stainless steel bars suitable for water treatment applications?

- Yes, stainless steel bars are suitable for water treatment applications. Stainless steel has excellent corrosion resistance properties, making it ideal for use in water treatment facilities where contact with water and various chemicals is common. Additionally, stainless steel bars are durable, hygienic, and can withstand high temperatures, making them well-suited for the harsh conditions often found in water treatment processes.

Send your message to us

stainless steel round bar

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords